Why are more manufacturers shifting towards High-Mix Low-Volume (HMLV) manufacturing in today's rapidly evolving market? As consumer demands become increasingly personalized and product lifecycles shrink, traditional mass production methods are no longer sufficient for many industries. HMLV manufacturing has emerged as a crucial strategy, enabling companies to produce a wide variety of products in smaller quantities while maintaining efficiency and quality.

From medical devices to luxury automobiles, this flexible manufacturing approach is revolutionizing how companies meet diverse customer needs. In this blog, we'll explore what HMLV manufacturing is, why it matters, and how businesses can implement it successfully.

What is High-Mix Low-Volume (HMLV) Manufacturing?

High-Mix Low-Volume (HMLV) manufacturing is a modern production approach that focuses on creating a wide variety of products in smaller quantities. This manufacturing strategy has emerged as a response to growing market demands for customization, flexibility, and rapid product development. Unlike traditional mass production methods, HMLV manufacturing emphasizes adaptability and customization over standardization and volume.

Breaking Down the "High-Mix" Component

High-Mix refers to the production of a diverse range of products or product variations within the same manufacturing facility. This includes:

Product Diversity: Multiple product lines with different specifications

Customization Options: Various designs, materials, and configurations

Production Flexibility: Ability to switch between different products quickly

Diverse Specifications: Different manufacturing requirements for each product type

Understanding the "Low-Volume" Aspect

Low-Volume production is characterized by:

Small Batch Sizes: Production quantities ranging from a few units to several thousand

Make-to-Order: Manufacturing based on specific customer requirements

Limited Production Runs: Shorter production cycles for each product variant

Quick Turnaround: Ability to complete small orders efficiently

How HMLV Differs from Traditional Manufacturing

Traditional Manufacturing vs. HMLV:

Production Volume:

Traditional: High-volume, standardized products

HMLV: Low-volume, customized products

Setup Frequency:

Customer Focus:

Traditional: Mass market, general consumer needs

HMLV: Specific customer requirements and specifications

Inventory Approach:

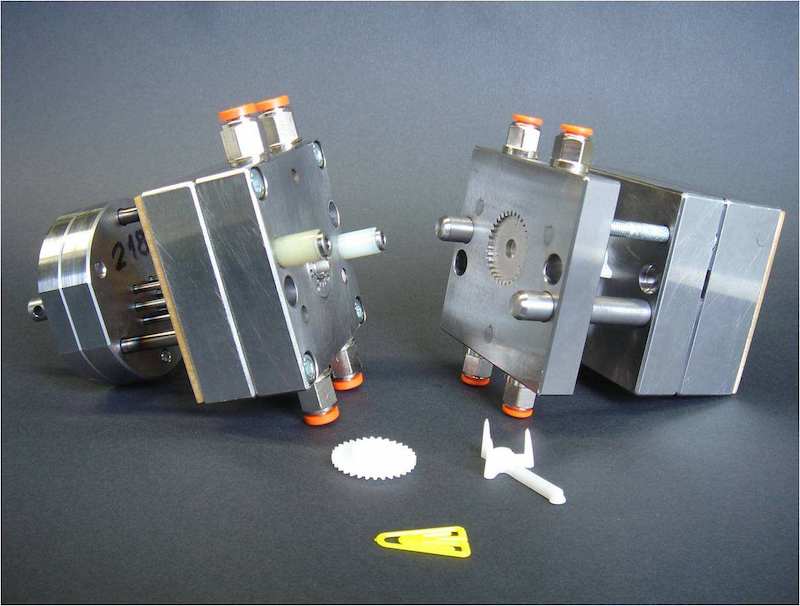

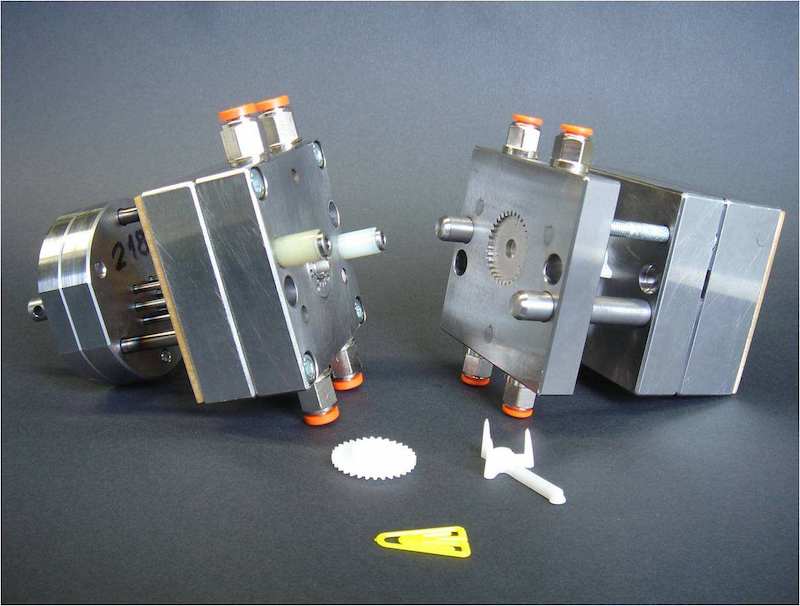

Key Characteristics of HMLV Production Systems

Core Features of HMLV manufacturing include:

Flexible Production Lines: Equipment and processes that can be quickly reconfigured for different products

Advanced Quality Control: Sophisticated inspection systems like industrial CT scanning for maintaining consistency across diverse product lines

Skilled Workforce: Highly trained operators capable of handling various production processes

Digital Integration: Smart manufacturing systems that can manage multiple product specifications and workflows

Efficient Setup Management: Quick changeover capabilities to switch between different products

Customer-Centric Approach: Production processes designed around specific customer needs and requirements

HMLV manufacturers typically operate in industries where customization and precision are crucial, such as:

This manufacturing approach represents a significant shift from traditional mass production methods, offering greater flexibility and customization capabilities while maintaining efficiency and quality standards. As market demands continue to evolve toward more personalized products, HMLV manufacturing has become increasingly important in modern manufacturing strategies.

The Growing Importance of HMLV Manufacturing

Current Market Trends Driving HMLV Adoption

Consumer Demand Shift is revolutionizing manufacturing approaches:

Growing preference for personalized products

Increasing demand for quick product iterations

Rising expectations for product customization

Shorter product life cycles

Market Dynamics pushing towards HMLV include:

Rapid technological advancements

Changing consumer preferences

Global competition

Need for faster time-to-market

Why Traditional Mass Production Isn't Always the Answer

Limitations of Mass Production in modern markets:

Inflexibility:

Unable to quickly adapt to market changes

Limited customization options

High inventory costs

Long production lead times

Market Mismatch:

Cannot efficiently handle small orders

Difficulty in product personalization

Excess inventory risk

Higher costs for small batches

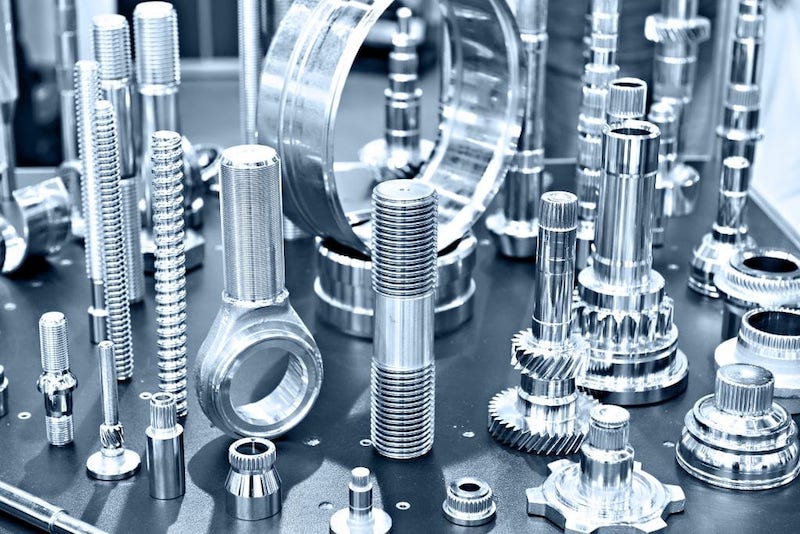

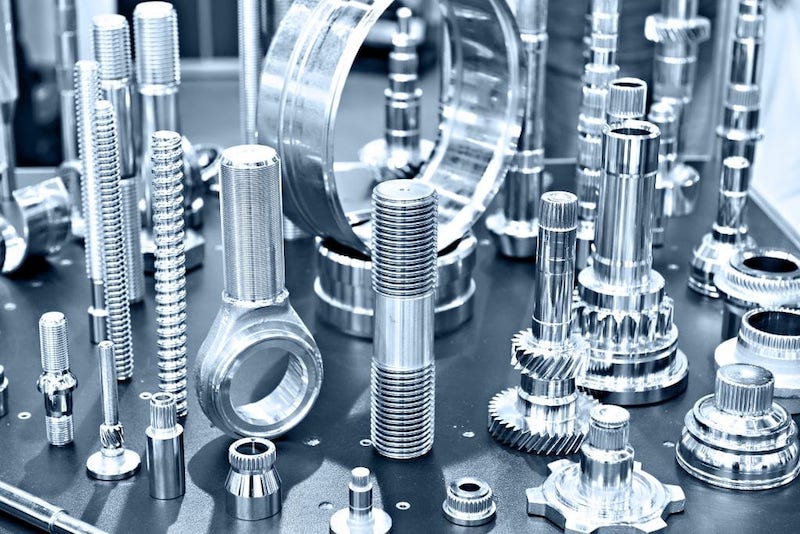

3. Real-World Applications of HMLV Manufacturing

HMLV manufacturing has found successful applications across various industries, each leveraging its unique capabilities to meet specific market demands and customer requirements.

3.1 Automotive Industry

Custom Luxury Vehicles represent a prime example of HMLV manufacturing:

Personalized interior configurations

Bespoke exterior modifications

Custom color schemes and finishes

Limited edition model production

Specialized Automotive Components include:

Custom exhaust systems

Modified engine components

Specialized suspension systems

Unique body panels and aerodynamic elements

Performance Parts Manufacturing focuses on:

High-performance brake systems

Custom turbocharger assemblies

Racing-specific components

Specialized transmission parts

3.2 Aerospace and Defense

Aircraft Components demonstrate complex HMLV applications:

Custom avionics enclosures

Specialized fastening systems

Unique structural elements

Mission-specific modifications

Custom Turbine Manufacturing involves:

Precision-engineered turbine blades

Specialized cooling systems

Custom combustion components

Modified engine parts

Specialized Military Equipment includes:

Custom communication systems

Specialized armor components

Mission-specific modifications

Unique tactical equipment

3.3 Medical Devices

Customized Implants showcase advanced HMLV capabilities:

Patient-specific joint replacements

Custom spinal implants

Personalized cranial plates

Tailored orthopedic solutions

Patient-Specific Surgical Instruments feature:

Custom cutting guides

Specialized surgical tools

Precise measurement devices

Unique positioning instruments

Dental Aligners and Prosthetics demonstrate precision HMLV:

Custom dental aligners

Personalized dental implants

Unique prosthetic components

Individual orthodontic appliances

3.4 Consumer Electronics

High-End Audio Equipment exhibits HMLV excellence:

Specialized Gadgets include:

Custom gaming controllers

Modified computer peripherals

Unique interface devices

Limited run electronic products

Custom Electronic Components feature:

Each of these applications demonstrates how HMLV manufacturing adapts to specific industry needs while maintaining high quality and efficiency. The success of HMLV in these industries highlights its versatility and effectiveness in meeting specialized production requirements. Through advanced technologies like industrial CT scanning and sophisticated quality control measures, manufacturers can ensure consistency and precision across diverse product lines while maintaining the flexibility needed for custom production.

4. Benefits of High-Mix Low-Volume Manufacturing

Production Flexibility Advantages

Adaptive Manufacturing Capabilities represent one of the most significant advantages of HMLV manufacturing. Companies can rapidly switch between different product lines, modify production processes, and accommodate varying batch sizes without significant downtime. This flexibility allows manufacturers to:

Quickly switch between different product lines

Modify production processes on demand

Accommodate varying batch sizes

Implement rapid design changes

Process Versatility enables organizations to maximize their production resources. By utilizing the same equipment and production lines for multiple product variants, companies can achieve higher equipment utilization rates and maintain a more flexible workforce. This includes:

Multiple product variants on the same line

Easy integration of new products

Efficient equipment utilization

Flexible workforce deployment

Customer Satisfaction Improvements

Customization Benefits directly impact customer satisfaction in HMLV manufacturing environments. By producing products tailored to specific customer requirements, companies can deliver exactly what their customers need, when they need it. This approach ensures:

Products tailored to specific customer needs

Rapid response to customer requests

Personalized product features

Enhanced customer engagement

Quality Focus becomes more achievable in HMLV manufacturing due to the smaller batch sizes and increased attention to detail. With fewer units being produced simultaneously, quality control measures can be more stringent, resulting in:

Detailed attention to each product

Stringent quality control

Reduced defect rates

Better product consistency

Inventory Optimization

Lean Inventory Management is a natural outcome of HMLV manufacturing approaches. By producing smaller batches based on actual demand, companies can significantly reduce their warehousing costs and minimize the risk of obsolescence, leading to:

Just-in-Time Production becomes more feasible under HMLV manufacturing. Companies can implement made-to-order strategies that minimize storage requirements and reduce waste, enabling:

Made-to-order manufacturing

Reduced storage requirements

Efficient material utilization

Decreased waste

Quick Market Response Capability

Market Adaptability gives HMLV manufacturers a significant competitive advantage. The ability to rapidly respond to market trends and test new product concepts allows companies to:

Rapidly respond to market trends

Test new product concepts

Address niche market demands

Launch products faster

Competitive Advantage is enhanced through faster time-to-market capabilities and quick design iterations. This responsiveness creates:

Innovation Opportunities

Product Development benefits significantly from HMLV manufacturing capabilities. The ability to quickly prototype and test new designs provides:

Technology Integration becomes more manageable in HMLV environments, enabling:

Advanced manufacturing techniques

Digital process optimization

Smart factory implementation

Continuous improvement

Strategic Benefits of HMLV manufacturing extend across multiple areas:

Business Growth:

Operational Excellence:

The combination of these benefits makes HMLV manufacturing an increasingly attractive option for companies looking to compete in today's dynamic market environment. By enabling greater flexibility, improved customer satisfaction, optimized inventory management, quick market response, and enhanced innovation capabilities, HMLV manufacturing provides a solid foundation for sustainable business growth and success.

5. Common Challenges in HMLV Manufacturing

5.1 Operational Challenges

Production Complexity presents significant challenges in HMLV environments. Managing multiple product variations simultaneously requires sophisticated scheduling systems and careful coordination of resources. Organizations must juggle diverse material requirements, complicated workflow patterns, and intricate process sequences, all while maintaining efficiency and meeting delivery deadlines.

Setup Time Management has become a critical concern in HMLV manufacturing. The frequent changeovers between different products can lead to significant downtime and reduced productivity. Companies must optimize their setup procedures while managing:

Complex tooling requirements

Equipment reconfiguration needs

Production line adjustments

Process validation steps

Quality verification procedures

Worker Training Requirements pose unique challenges in HMLV environments. The diverse nature of production demands a highly skilled workforce capable of handling multiple processes and products. Employees need extensive training to:

Develop multiple technical skills

Maintain process knowledge

Adapt to frequent changes

Handle various equipment types

Understand quality requirements

Equipment Utilization challenges stem from the need to balance flexibility with efficiency. Machinery must be adaptable enough to handle various product specifications while maintaining optimal performance levels. This requires careful planning of:

5.2 Quality Control Challenges

Maintaining Consistent Quality becomes increasingly complex in HMLV manufacturing. The variety of products and frequent process changes make it difficult to maintain uniform quality standards. Organizations must develop robust quality control systems that can adapt to different product specifications while ensuring consistent output quality.

Inspection Methods require significant sophistication in HMLV environments. Companies need to implement:

Multiple inspection protocols

Advanced testing procedures

Varied quality criteria

Complex measurement systems

Specialized inspection equipment

Documentation Requirements have become more demanding with HMLV manufacturing. Each product variant needs detailed documentation covering:

Process specifications

Quality parameters

Testing procedures

Compliance requirements

Traceability records

Quality Assurance Processes need careful attention in HMLV settings. Organizations must develop comprehensive systems that can handle the complexity of multiple product lines while maintaining strict quality standards. This includes implementing:

Robust validation procedures

Regular auditing processes

Continuous monitoring systems

Corrective action protocols

Performance tracking methods

5.3 Cost Management

Pricing Strategies in HMLV manufacturing require careful consideration of multiple factors. Companies must develop pricing models that account for:

Variable production costs

Setup time expenses

Small batch inefficiencies

Customization requirements

Market positioning

Resource Allocation becomes particularly challenging in HMLV environments. Organizations must carefully balance their resources across multiple product lines while maintaining efficiency. This involves strategic planning of:

Labor distribution

Equipment scheduling

Material management

Time allocation

Capacity utilization

Investment Considerations need thorough evaluation in HMLV manufacturing. Companies must carefully assess their investment needs in:

Cost Reduction Techniques focus on maintaining efficiency despite the complexity of HMLV operations. Organizations must implement strategies for:

The successful management of these challenges requires a balanced approach that combines strategic planning with operational excellence. Organizations must develop comprehensive solutions that address both immediate operational needs and long-term strategic goals while maintaining the flexibility and responsiveness that HMLV manufacturing demands.

6. Implementing HMLV Manufacturing Successfully

6.1 Essential Technologies

Industrial CT Scanning has revolutionized quality control in HMLV manufacturing. This technology enables non-destructive testing and inspection of complex parts, providing detailed insight into internal structures, early defect detection, and comprehensive quality validation without compromising products.

Advanced Inspection Systems ensure quality consistency across diverse product lines. These systems combine automation with precise measurement capabilities, providing real-time monitoring, automated defect detection, and data-driven quality management for multiple product variations.

Digital Work Instructions transform production floor operations by ensuring consistent process execution while maintaining flexibility. They provide clear visual guidance, enable real-time updates, and serve as valuable training tools for operators managing multiple processes.

Manufacturing Execution Systems (MES) integrate various aspects of production management. These systems provide real-time visibility, enable efficient resource allocation, and facilitate quick response to production changes across multiple product lines.

6.2 Process Optimization

Standardizing Methods balances consistency with flexibility in HMLV implementation. Organizations establish standard procedures while maintaining adaptability for different product requirements, reducing errors and improving efficiency across product lines.

Flow Optimization focuses on improving material movement, production sequencing, and resource utilization. This includes minimizing bottlenecks, reducing setup times, and ensuring smooth transitions between different product runs.

Communication Improvements ensure effective coordination in complex HMLV operations. Clear communication channels, regular team meetings, and digital tools for real-time updates help maintain smooth operations across departments.

Inventory Management Strategies handle multiple product lines while maintaining efficient inventory levels. This includes implementing just-in-time systems, smart storage solutions, and effective forecasting methods.

6.3 Workforce Considerations

Training Requirements prepare workers for handling multiple products and processes. Comprehensive programs cover technical skills, quality awareness, and safety procedures, supported by continuous learning opportunities.

Skill Development enables workers to manage multiple processes while maintaining quality standards. Structured approaches combine formal training with on-the-job experience, ensuring workforce capability across different product lines.

Team Organization promotes cross-functional capabilities and clear communication. Teams are structured to respond quickly to changing production requirements while maintaining consistent quality and efficiency.

Knowledge Management captures and shares best practices, procedures, and expertise. This includes maintaining information repositories, mentoring programs, and effective methods for knowledge transfer across the organization.

The successful implementation of HMLV manufacturing requires integrating technology, optimizing processes, and developing workforce capabilities. Regular assessment and adjustment of strategies ensure long-term success in these complex manufacturing environments.

Conclusion

Looking ahead, HMLV manufacturing will continue to grow in importance as markets demand more personalized products and shorter production cycles. Success in this manufacturing approach requires careful balance between flexibility and efficiency, supported by continuous improvement in processes, technology, and workforce capabilities.

At TEAM MFG, we specialize in High-Mix Low-Volume manufacturing solutions tailored to your unique needs. Whether you're looking to enhance production flexibility, improve quality control, or optimize your manufacturing processes, our expert team is here to help. Contact us today to discover how our HMLV expertise can drive your manufacturing success.

Transform your manufacturing future with TEAM MFG.