Have you ever wondered how complex plastic parts with intricate details are made? The answer lies in a clever technique called injection molding undercuts. But what exactly are undercuts, and why are they so important?

Undercuts are features that prevent the easy removal of a part from its mold. They're crucial for creating parts with enhanced functionality, improved assembly, and reduced need for secondary operations. However, designing and molding undercuts comes with its own set of challenges.

In this post, you'll learn what undercuts are, why they are important, and how to manage their complexities effectively.

What are Injection Molding Undercuts?

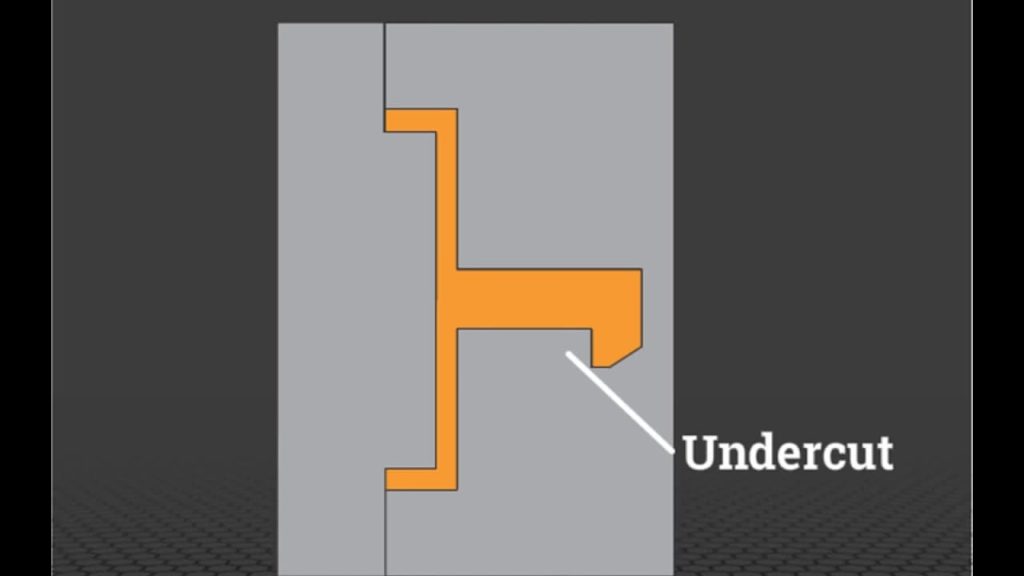

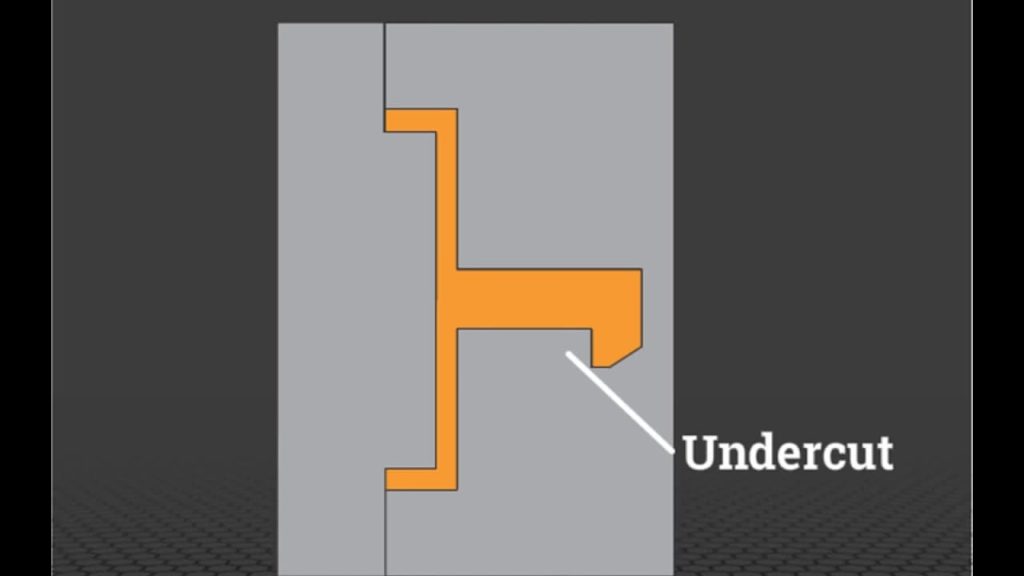

Injection molding undercuts are features that prevent a part from being easily ejected from its mold. They're like hooks or overhangs that "lock" the part in place. Let's explore them in detail.

Detailed Explanation of Undercuts

Undercuts are typically formed when a part has:

Protrusions

Holes

Cavities

Recessed areas

These features aren't perpendicular to the mold's parting line. This makes it challenging to remove the part without damaging it.

Types of Undercuts

There are two main types of undercuts:

Internal undercuts

External undercuts

Found on the outer surface

Examples: clips, hooks, flanges

Common Applications

Undercuts are used in various industries for:

Consumer electronics

Button slots

Battery compartments

Medical devices

Luer locks

Snap-fit assemblies

Automotive components

Clips and fasteners

Fluid channels

| Industry | Application | Benefit |

| Electronics | Button slots | Easy access |

| Medical | Luer locks | Secure connection |

| Automotive | Clips | Quick assembly |

Undercuts add functionality and simplify assembly. They're a key aspect of injection molding design.

Importance of Undercuts in Injection Molded Parts

Undercuts play a crucial role in injection molded parts. They offer several benefits that make them indispensable in modern manufacturing.

Enhanced Functionality and Design Complexity

Undercuts allow designers to create parts with:

Intricate geometries

Interlocking features

Snap-fits and hinges

These elements enhance the functionality of the part. They also enable more complex designs that would be impossible without undercuts.

Improved Assembly and Disassembly

Undercuts facilitate easy assembly and disassembly of parts. They allow for:

Quick snap-fit connections

Reduced need for screws or adhesives

Easy replacement of worn or damaged components

This streamlines the assembly process and makes maintenance a breeze.

Reduced Need for Secondary Operations

By incorporating undercuts directly into the molded part, you can:

Eliminate the need for post-molding drilling or machining

Reduce the number of assembly steps

Minimize the risk of human error

This saves time, effort, and resources in the manufacturing process.

Cost-Effectiveness in Mass Production

Undercuts contribute to cost-effectiveness, especially in high-volume production runs. They enable:

Faster cycle times

Reduced material waste

Lower assembly costs

Over time, these savings add up, making undercuts an economical choice for mass production.

| Benefit | Impact |

| Enhanced functionality | Enables complex designs |

| Improved assembly | Streamlines production |

| Reduced secondary ops | Saves time and resources |

| Cost-effectiveness | Lowers overall expenses |

Techniques for Achieving Injection Molding Undercuts

Creating undercuts in injection molding requires specialized techniques. Let's explore the most common methods and their pros and cons.

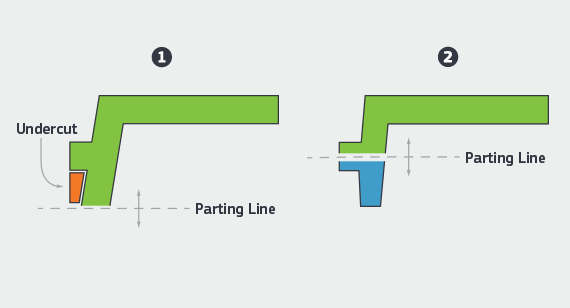

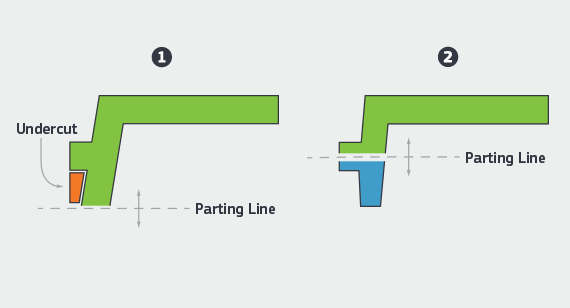

1. Parting Line Adjustment

Parting line placement is crucial for undercut design. It involves:

This allows the part to be ejected without interference.

Advantages:

Limitations:

Tips for optimizing parting line design:

Consider part functionality and aesthetics

Minimize the number of parting lines

Ensure proper venting and cooling

2. Side-Actions

Side-actions are movable mold components that create undercuts. They work by:

Types of side-actions:

Hydraulic - powered by hydraulic pressure

Mechanical - driven by cams or linkages

Pneumatic - actuated by compressed air

Design considerations:

Ensure proper clearance and alignment

Plan for adequate cooling and venting

Consider the force required to operate the side-action

Benefits:

Drawbacks:

3. Bump-Offs

Bump-offs are raised sections on the mold that compress during ejection. They allow the part to flex and release from the undercut.

Suitable materials for bump-offs:

Design guidelines:

Ensure sufficient draft angles

Use smooth, rounded surfaces

Consider the material's compression limits

Advantages:

Disadvantages:

4. Hand-Loaded Inserts

Hand-loaded inserts are manually placed in the mold before each cycle. They create undercuts by:

When to use hand-loaded inserts:

Design and material considerations:

Pros:

Cons:

5. Sliding Shutoffs (Telescoping Shutoffs)

Sliding shutoffs are mold components that move parallel to the ejection direction. They create undercuts by:

Applications:

Design tips:

Ensure proper alignment and clearance

Use wear-resistant materials for the shutoff surfaces

Plan for adequate cooling and venting

Advantages:

Limitations:

6. Collapsible Cores

Collapsible cores are mold components that collapse or retract during ejection. They allow the part to release from internal undercuts.

Types of collapsible cores:

Mechanical - driven by cams or linkages

Hydraulic - actuated by hydraulic pressure

Design considerations:

Ensure proper alignment and timing of the core movement

Plan for adequate cooling and venting

Consider the force required to collapse the core

Benefits:

Drawbacks:

Choosing the right technique depends on factors like:

Design Considerations for Undercuts

When designing parts with undercuts, there are several key factors to keep in mind. Let's explore them in detail.

Draft Angles

Importance of Draft Angles

Draft angles are crucial for undercut design. They help ensure:

Without proper draft, parts can stick or deform during ejection.

Recommended Draft Angles

The optimal draft angle depends on the specific design. However, here are some general guidelines:

| Feature Type | Recommended Draft |

| External walls | 1-2 degrees |

| Internal walls | 2-3 degrees |

| Ribs and bosses | 0.5-1 degree per side |

Increasing draft angles can improve part release but may affect aesthetics.

Wall Thickness

Maintaining Uniform Wall Thickness

Consistent wall thickness is essential for undercut design. It ensures:

Always follow the resin manufacturer's guidelines for wall thickness.

Impact on Part Integrity

Variations in wall thickness can lead to:

Weak spots or stress concentrations

Uneven material flow and packing

Visible defects on the part surface

Maintain a uniform thickness throughout the part for optimal results.

Ribs and Radiuses

Supporting Structures in Molded Parts

Ribs are thin, wall-like features that provide structural support. They help:

Reinforce large, flat surfaces

Prevent sink marks and warping

Improve part rigidity and strength

Use ribs strategically to enhance the performance of undercut parts.

Radiusing Internal Corners

Sharp internal corners are prone to stress concentrations. To mitigate this:

Radiused corners distribute stress more evenly, improving part durability.

Designing for Manufacturability (DFM) in Undercut Injection Molding

DFM is a crucial aspect of successful undercut design. Let's dive into its principles and benefits.

Overview of DFM Principles

DFM is a design approach that focuses on ease of manufacturing. Its key principles include:

Simplifying part geometry

Minimizing the number of components

Designing for efficient assembly

Considering material properties and limitations

By applying DFM, designers can create parts that are easier and cheaper to produce.

Importance of DFM in Undercut Design

Undercuts add complexity to the injection molding process. DFM helps manage this complexity by:

Identifying potential manufacturing issues early in the design phase

Optimizing part geometry for specific molding techniques

Ensuring the design is compatible with the chosen material

Reducing the risk of defects and production delays

Incorporating DFM is essential for successful undercut design.

Common DFM Guidelines for Undercuts

Here are some key DFM tips for designing undercuts:

Minimize undercut depth and complexity

Use consistent wall thickness throughout the part

Provide adequate draft angles for easy ejection

Avoid sharp corners and edges

Consider the parting line location and its impact on the undercut

Use standard materials and tolerances whenever possible

Following these guidelines can help streamline the molding process.

Benefits of Incorporating DFM

Implementing DFM in undercut design offers several advantages:

Reduced production costs and lead times

Improved part quality and consistency

Enhanced collaboration between design and manufacturing teams

Faster time-to-market for new products

Increased overall manufacturing efficiency

| DFM Benefit | Impact |

| Lower costs | More competitive pricing |

| Faster production | Shorter lead times |

| Better quality | Higher customer satisfaction |

| Enhanced efficiency | Increased profitability |

Challenges and Solutions

Designing and molding undercuts comes with its fair share of challenges. Let's explore some common issues and their solutions.

Material and Design Challenges

Managing Rigid Materials and Complex Geometries

Rigid materials like polycarbonate and ABS can be challenging for undercut design. They:

Complex geometries with deep or narrow undercuts further complicate the process.

Solutions to Common Design Issues

To overcome these challenges, designers can:

Use more flexible materials like TPE or nylon

Optimize wall thickness and draft angles

Incorporate side-actions or collapsible cores for complex features

Collaboration between designers and molders is key to finding effective solutions.

Aesthetic and Functional Considerations

Dealing with Visible Parting Lines

Parting lines are often visible on parts with undercuts. They can:

To minimize their impact, consider:

Adjusting the parting line location

Using texture or color to hide the lines

Employing sliding shutoffs for a seamless appearance

Ensuring Functional Integrity

Undercuts can also affect the functional performance of the part. To maintain integrity:

Conduct thorough design reviews and simulations

Test prototypes under real-world conditions

Make necessary design adjustments based on feedback

Finding the right balance between functionality and manufacturability is crucial.

Cost Implications

Balancing Complexity and Production Costs

More complex undercuts generally mean higher production costs. This is due to:

Increased mold complexity and maintenance

Longer cycle times and higher material usage

Additional labor for hand-loaded inserts or secondary operations

Designers must weigh the benefits of undercuts against their cost impact.

Long-Term Impacts on Investment

The upfront investment in a complex mold with undercuts can be significant. However, it's important to consider:

A well-designed undercut can pay off in the long run, despite initial costs.

| Challenge | Solution |

| Rigid materials | Use flexible alternatives |

| Visible parting lines | Adjust location or use texture |

| Functional integrity | Conduct thorough testing |

| Production costs | Balance complexity and benefits |

Summary

In summary, achieving injection molding undercuts involves several key techniques. We explored parting lines, side-actions, bumpoffs, hand-loaded inserts, and telescoping shutoffs. Selecting the right technique is crucial for success. Material choice and Design for Manufacturability (DFM) are also vital in undercut molding. Collaborating with experts ensures the best results. Effective undercut design requires both knowledge and precision.

Have a complex undercut design? Team Mfg has the expertise to bring it to life. Submit your CAD files today at https://www.team-mfg.com for a fast, free quote. Our experts are ready to assist you. Get started now!