VDI 3400 is a vital texture standard developed by the Society of German Engineers (Verein Deutscher Ingenieure) that defines surface finishes for mold-making. This comprehensive standard covers 45 distinct texture grades, ranging from smooth to rough finishes, catering to various industries and applications.

Understanding VDI 3400 is crucial for mold makers, designers, and marketers who strive to create high-quality, visually appealing, and functionally optimal products. By adhering to this standard, professionals can ensure consistent texture quality across different manufacturing processes, materials, and end-use requirements, ultimately leading to improved product performance and customer satisfaction.

Understanding VDI 3400 Standards

What is VDI 3400 Texture?

VDI 3400 is a comprehensive texture standard developed by the Society of German Engineers (Verein Deutscher Ingenieure) to define surface finishes for mold-making. This standard has become widely adopted globally, not just in Germany, as a reliable reference for achieving consistent and precise surface textures in various manufacturing processes.

The VDI 3400 standard covers a wide range of texture types, from smooth to rough finishes, catering to diverse industry requirements. It consists of 12 distinct texture grades, ranging from VDI 12 to VDI 45, each with specific surface roughness values and applications.

VDI 3400 Grade | Surface Roughness (Ra, µm) | Typical Applications |

VDI 12 | 0.40 | Low polish parts |

VDI 15 | 0.56 | Low polish parts |

VDI 18 | 0.80 | Satin finish |

VDI 21 | 1.12 | Dull finish |

VDI 24 | 1.60 | Dull finish |

VDI 27 | 2.24 | Dull finish |

VDI 30 | 3.15 | Dull finish |

VDI 33 | 4.50 | Dull finish |

VDI 36 | 6.30 | Dull finish |

VDI 39 | 9.00 | Dull finish |

VDI 42 | 12.50 | Dull finish |

VDI 45 | 18.00 | Dull finish |

The primary applications of VDI 3400 textures include:

l Automotive industry: Interior and exterior components

l Electronics: Housings, casings, and buttons

l Medical devices: Equipment and instrument surfaces

l Consumer goods: Packaging, appliances, and tools

Categories of VDI 3400 Textures

The VDI 3400 standard encompasses a wide range of texture categories, each with specific surface roughness values and applications. These categories are designated by numbers ranging from VDI 12 to VDI 45, with increasing surface roughness as the numbers progress.

Here's a breakdown of the VDI 3400 texture categories and their corresponding Ra and Rz values:

VDI 3400 Grade | Ra (µm) | Rz (µm) | Applications |

VDI 12 | 0.40 | 1.50 | Low polish parts, e.g., mirrors, lenses |

VDI 15 | 0.56 | 2.40 | Low polish parts, e.g., automotive interior trim |

VDI 18 | 0.80 | 3.30 | Satin finish, e.g., household appliances |

VDI 21 | 1.12 | 4.70 | Dull finish, e.g., electronic device housings |

VDI 24 | 1.60 | 6.50 | Dull finish, e.g., automotive exterior parts |

VDI 27 | 2.24 | 10.50 | Dull finish, e.g., industrial equipment |

VDI 30 | 3.15 | 12.50 | Dull finish, e.g., construction tools |

VDI 33 | 4.50 | 17.50 | Dull finish, e.g., agricultural machinery |

VDI 36 | 6.30 | 24.00 | Dull finish, e.g., heavy-duty equipment |

VDI 39 | 9.00 | 34.00 | Dull finish, e.g., mining equipment |

VDI 42 | 12.50 | 48.00 | Dull finish, e.g., oil and gas industry components |

VDI 45 | 18.00 | 69.00 | Dull finish, e.g., extreme environment applications |

The Ra value represents the arithmetic average of the surface roughness profile, while the Rz value indicates the average maximum height of the profile. These values help engineers and designers select the appropriate VDI 3400 texture category for their specific application, taking into account factors such as:

l Material compatibility

l Desired surface appearance

l Functional requirements (e.g., slip resistance, wear resistance)

l Manufacturing feasibility and cost-effectiveness

VDI 3400 vs. Other Texturing Standards

While VDI 3400 is a widely recognized and utilized texture standard, it is essential to understand how it compares to other international standards. This section will provide a comparative analysis of VDI 3400 with other prominent texturing standards, highlighting their unique aspects, advantages, and potential drawbacks for specific applications.

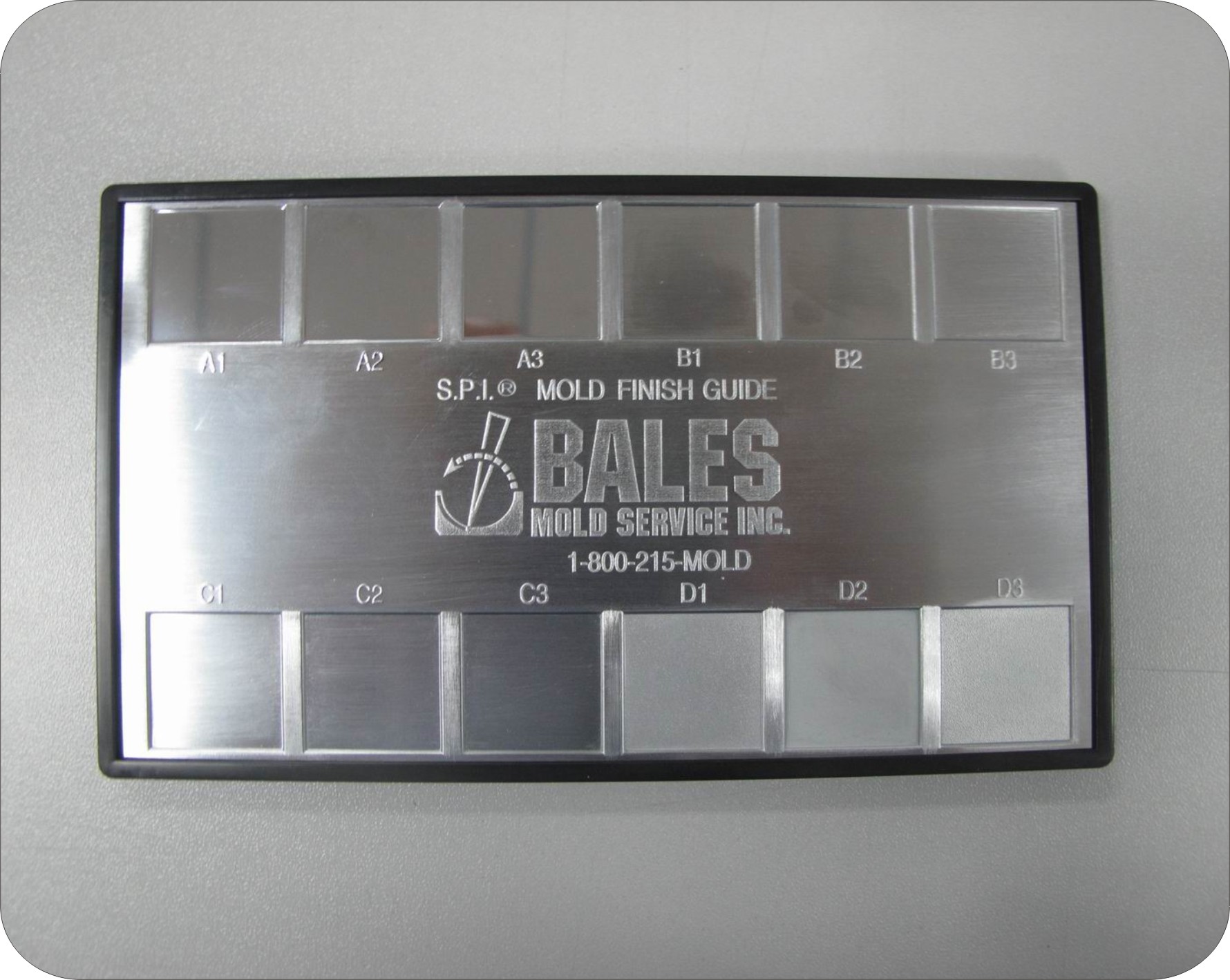

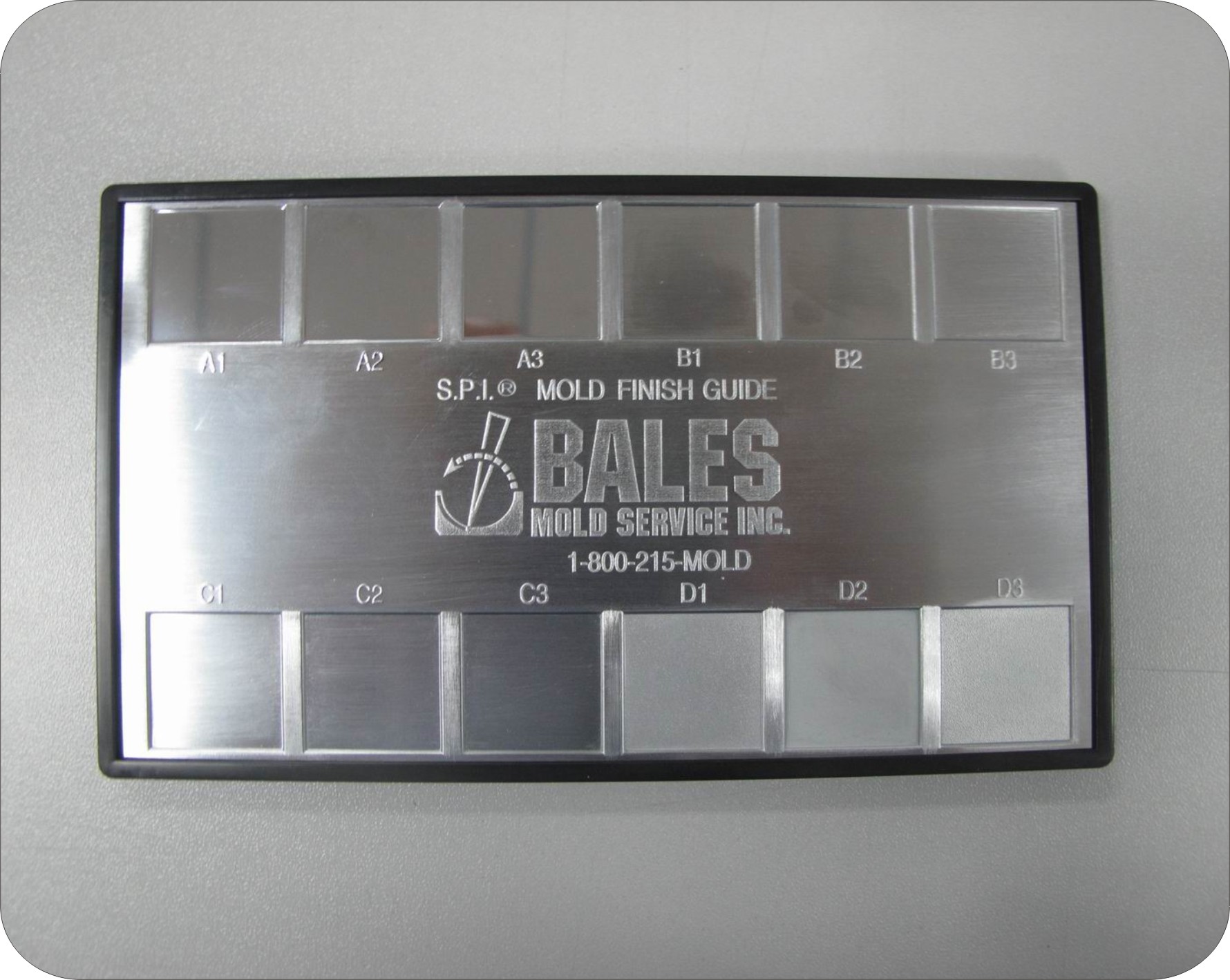

VDI 3400 vs. SPI Finish

The SPI (Society of the Plastics Industry) finish standard is commonly used in the United States and focuses on the smoothness of the surface finish. In contrast, VDI 3400 emphasizes surface roughness and is more widely adopted in Europe and other parts of the world.

Aspect | VDI 3400 | SPI Finish |

Focus | Surface roughness | Surface smoothness |

Geographic prevalence | Europe and worldwide | United States |

Number of grades | 12 (VDI 12 to VDI 45) | 12 (A-1 to D-3) |

Application | Mold texturing | Mold polishing |

VDI 3400 vs. Mold-Tech Textures

Mold-Tech, a US-based company, provides custom texturing services and offers a wide range of texture patterns. While Mold-Tech textures offer greater flexibility in design, VDI 3400 provides a standardized approach to surface roughness.

Aspect | VDI 3400 | Mold-Tech Textures |

Texture types | Standardized roughness grades | Custom texture patterns |

Flexibility | Limited to 12 grades | High, can create unique patterns |

Consistency | High, due to standardization | Depends on the specific texture |

Cost | Generally lower | Higher, due to customization |

VDI 3400 vs. Yick Sang Textures

Yick Sang, a Chinese company, offers a wide range of texturing services and is popular in China and other Asian countries. While Yick Sang textures provide a broad selection of patterns, VDI 3400 offers a more standardized approach to surface roughness.

Aspect | VDI 3400 | Yick Sang Textures |

Texture types | Standardized roughness grades | Wide variety of texture patterns |

Geographic prevalence | Europe and worldwide | China and Asian countries |

Consistency | High, due to standardization | Varies depending on the texture |

Cost | Generally lower | Moderate, due to variety of options |

Explanation of Measurement Units

To fully understand the VDI 3400 standard, it is crucial to grasp the units of measurement used to quantify surface roughness. The VDI 3400 scale primarily employs two units: Ra (Roughness average) and Rz (Average maximum height of the profile). These units are typically expressed in micrometers (µm) or microinches (µin).

1. Ra (Roughness average)

a. Ra is the arithmetic average of the absolute values of the profile height deviations from the mean line within the evaluation length.

b. It provides a general description of the surface texture and is the most commonly used parameter in the VDI 3400 standard.

c. Ra values are expressed in micrometers (µm) or microinches (µin).1 µm = 0.001 mm = 0.000039 inches

i. 1 µin = 0.000001 inches = 0.0254 µm

2. Rz (Average maximum height of the profile)

a. Rz is the average of the maximum peak-to-valley heights of five consecutive sampling lengths within the evaluation length.

b. It provides information about the vertical characteristics of the surface texture and is often used in conjunction with Ra.

c. Rz values are also expressed in micrometers (µm) or microinches (µin).

The following table shows the Ra and Rz values for each VDI 3400 grade in both micrometers and microinches:

VDI 3400 Grade | Ra (µm) | Ra (µin) | Rz (µm) | Rz (µin) |

VDI 12 | 0.40 | 16 | 1.50 | 60 |

VDI 15 | 0.56 | 22 | 2.40 | 96 |

VDI 18 | 0.80 | 32 | 3.30 | 132 |

VDI 21 | 1.12 | 45 | 4.70 | 188 |

VDI 24 | 1.60 | 64 | 6.50 | 260 |

VDI 27 | 2.24 | 90 | 10.50 | 420 |

VDI 30 | 3.15 | 126 | 12.50 | 500 |

VDI 33 | 4.50 | 180 | 17.50 | 700 |

VDI 36 | 6.30 | 252 | 24.00 | 960 |

VDI 39 | 9.00 | 360 | 34.00 | 1360 |

VDI 42 | 12.50 | 500 | 48.00 | 1920 |

VDI 45 | 18.00 | 720 | 69.00 | 2760 |

Application and Benefits

Application of VDI 3400 in Different Industries

VDI 3400 textures find extensive application across various industries, owing to their versatility and standardized nature. Here are some examples of how different sectors utilize VDI 3400 textures in their manufacturing processes:

1. Automotive Industry

a. Interior components: Dashboard, door panels, and trim parts

b. Exterior components: Bumpers, grilles, and mirror housings

c. Example: VDI 27 texture used on a car's dashboard for a matte, low-gloss finish

2. Aerospace Industry

a. Aircraft interior components: Overhead bins, seat parts, and wall panels

b. Example: VDI 30 texture applied to aircraft interior trim for a consistent, durable finish

3. Consumer Electronics

a. Device housings: Smartphones, laptops, and television sets

b. Buttons and knobs: Remote controls, appliances, and gaming controllers

c. Example: VDI 21 texture used on a smartphone's back cover for a smooth, satin finish

Benefits of Using VDI 3400 Textures

Implementing VDI 3400 textures in product design and manufacturing offers several advantages, including:

1. Improved Product Durability

a. Consistent surface finish enhances wear resistance and longevity

b. Reduced risk of scratches, abrasions, and other surface damage

2. Enhanced Aesthetic Appeal

a. Wide range of texture options to suit various design preferences

b. Consistent surface appearance across different production batches

3. Increased Production Efficiency

a. Standardized textures facilitate easier mold design and manufacturing

b. Reduced lead times and increased productivity due to streamlined processes

4. Improved Customer Satisfaction

a. High-quality surface finishes contribute to better user experiences

b. Consistent product appearance and durability lead to increased customer loyalty

How to Implement VDI 3400 Textures in Mold Design

To successfully incorporate VDI 3400 textures into your mold design, follow these steps:

1. Determine the desired surface finish based on product requirements and aesthetic preferences

2. Select the appropriate VDI 3400 texture grade (e.g., VDI 24 for a dull finish)

3. Consider the material properties and select suitable drafting angles (refer to section 3.4)

4. Specify the chosen VDI 3400 texture grade on the mold drawing or CAD model

5. Communicate the texture requirements clearly to the mold maker

6. Verify the texture quality during mold trials and adjust as necessary

When selecting textures, consider the following factors:

l Material compatibility: Ensure the texture is suitable for the chosen plastic material

l Desired finish: Choose a texture grade that aligns with the intended surface appearance

l Product release: Opt for textures that facilitate easy part ejection from the mold

Material-Specific Drafting Angles

Drafting angles play a crucial role in mold design, as they facilitate the easy removal of the molded part from the mold cavity. The appropriate drafting angle depends on the material being used and the surface texture specified by the VDI 3400 standard. Insufficient drafting angles can lead to part sticking, surface defects, and increased wear on the mold surface.

Here's a table displaying the recommended drafting angles for common plastic materials according to VDI 3400 texture grades:

Material | VDI 3400 Grade | Drafting Angle (degrees) |

ABS | 12 - 21 | 0.5° - 1.0° |

24 - 33 | 1.0° - 2.5° |

36 - 45 | 3.0° - 6.0° |

PC | 12 - 21 | 1.0° - 1.5° |

24 - 33 | 1.5° - 3.0° |

36 - 45 | 4.0° - 7.0° |

PA | 12 - 21 | 0.0° - 0.5° |

24 - 33 | 0.5° - 2.0° |

36 - 45 | 2.5° - 5.0° |

*Note: The drafting angles provided above are general guidelines. Always consult with your material supplier and mold maker for specific recommendations based on your project requirements.

Key points to consider when determining drafting angles:

l Higher VDI 3400 grades (rougher textures) require larger drafting angles to ensure proper part release.

l Materials with higher shrinkage rates, such as ABS and PC, generally require larger drafting angles compared to materials like PA.

l Complex part geometries, such as deep ribs or undercuts, may necessitate larger drafting angles to prevent sticking and facilitate ejection.

l Textured surfaces typically require larger drafting angles compared to smooth surfaces to maintain the desired surface finish and avoid deformation during ejection.

By selecting the appropriate drafting angles based on the material and VDI 3400 texture grade, you can ensure:

l Easier part removal from the mold

l Reduced risk of surface defects and deformation

l Improved mold durability and longevity

l Consistent surface texture across multiple production runs

Technical Aspects

Production Techniques for VDI 3400 Textures

VDI 3400 textures can be produced using various techniques, each with its own advantages and limitations. The two most common methods are Electrical Discharge Machining (EDM) and chemical etching.

1. Electrical Discharge Machining (EDM)

a. EDM is a highly precise and controlled process that uses electrical sparks to erode the mold surface and create the desired texture.

b. The process involves a conductive electrode (usually graphite or copper) that is shaped to the inverse of the desired texture pattern.

c. Electrical sparks are generated between the electrode and the mold surface, gradually removing material and creating the texture.

d. EDM is capable of producing intricate and detailed textures, making it suitable for complex designs and high-precision applications.

2. Chemical Etching

a. Chemical etching is a cost-effective and efficient method for creating VDI 3400 textures on large surface areas.

b. The process involves applying a chemically resistant mask to the mold surface, leaving the areas to be textured exposed.

c. The mold is then immersed in an acidic solution, which etches away the exposed areas, creating the desired texture.

d. Chemical etching is particularly useful for achieving uniform textures across large mold surfaces and is suitable for less complex designs.

Other traditional texturing methods, such as sandblasting and manual polishing, can also be used to create VDI 3400 textures. However, these methods are less precise and may result in inconsistencies across the mold surface.

Quality Assurance and Standards Compliance

To ensure the consistency and quality of VDI 3400 textures, manufacturers must implement robust quality assurance processes and adhere to international standards.

Key aspects of quality assurance in VDI 3400 texture production include:

l Regular calibration and maintenance of EDM machines and chemical etching equipment

l Strict control of process parameters, such as electrode wear, etching time, and solution concentration

l Visual and tactile inspection of mold surfaces to ensure texture uniformity and absence of defects

l Use of surface roughness measuring instruments (e.g., profilometers) to verify compliance with VDI 3400 specifications

Compliance with international standards, such as ISO 25178 (Surface texture: Areal) and ISO 4287 (Geometrical Product Specifications (GPS) - Surface texture: Profile method), ensures that VDI 3400 textures meet globally recognized quality and consistency requirements.

Techniques for Measuring Surface Finishes

Accurate measurement of surface roughness is crucial for verifying compliance with VDI 3400 specifications and ensuring the quality of the final product. The most common method for measuring surface roughness is using a profilometer.

1. Profilometers

a. Profilometers are precision instruments that use a stylus or laser to trace the surface profile and measure the surface roughness.

b. They provide highly accurate and repeatable measurements, making them the preferred choice for quality control and inspection purposes.

c. Profilometers can measure various surface roughness parameters, such as Ra (arithmetic mean roughness) and Rz (maximum height of profile), as specified in the VDI 3400 standard.

2. Alternative Measurement Methods

a. Surface finish gauges, also known as comparators, are visual and tactile tools that allow for quick and easy comparison of surface textures against reference samples.

b. While surface finish gauges are less precise than profilometers, they are useful for rapid on-site inspections and preliminary quality checks.

Measurement errors, such as improper calibration of instruments or incorrect sampling techniques, can lead to inaccurate surface roughness readings and potentially impact the final product quality. To minimize measurement errors, it is essential to:

l Regularly calibrate and maintain measuring instruments

l Follow standard measurement procedures and sampling techniques

l Ensure that the mold surface is clean and free from debris or contaminants before measurement

l Perform multiple measurements across the mold surface to account for potential variations

By implementing proper quality assurance processes, adhering to international standards, and utilizing accurate surface roughness measurement techniques, manufacturers can consistently produce high-quality VDI 3400 textures that meet the required specifications and ensure customer satisfaction.

Comparing Global Texture Standards

VDI 3400 vs. SPI Finish Standards

When discussing surface texture standards, it is essential to understand the differences and similarities between the widely used VDI 3400 and SPI (Society of the Plastics Industry) finish standards. While both standards aim to provide a consistent way of specifying surface textures, they have distinct focuses and application areas.

Key differences between VDI 3400 and SPI finish standards:

1. Focus

a. VDI 3400: Emphasizes surface roughness and is primarily used for mold texturing.

b. SPI Finish: Focuses on surface smoothness and is mainly used for mold polishing.

2. Measurement Units

a. VDI 3400: Measured in Ra (average roughness) and Rz (average maximum height of the profile), typically in micrometers (μm).

b. SPI Finish: Measured in Ra (average roughness), typically in microinches (μin).

3. Standard Range

a. VDI 3400: Covers 45 grades, from VDI 0 (smoothest) to VDI 45 (roughest).

b. SPI Finish: Covers 12 grades, from A-1 (smoothest) to D-3 (roughest).

4. Geographical Prevalence

a. VDI 3400: Widely used in Europe and other parts of the world.

b. SPI Finish: Primarily used in the United States.

When choosing between VDI 3400 and SPI finish standards, consider the following factors:

l Project location and industry norms

l Required surface roughness or smoothness

l Mold material and manufacturing processes

l Compatibility with other project specifications

To facilitate the comparison between VDI 3400 and SPI finish standards, here's a conversion table that matches the closest grades between the two standards:

VDI 3400 Grade | SPI Finish Grade | Ra (μm) | Ra (μin) |

0-5 | A-3 | 0.10 | 4-8 |

6-10 | B-3 | 0.20 | 8-12 |

11-12 | C-1 | 0.35 | 14-16 |

13-15 | C-2 | 0.50 | 20-24 |

16-17 | C-3 | 0.65 | 25-28 |

18-20 | D-1 | 0.90 | 36-40 |

21-29 | D-2 | 1.60 | 64-112 |

30-45 | D-3 | 4.50 | 180-720 |

*Note: The conversion table provides approximate matches between the two standards based on Ra values. Always refer to the specific standard's documentation for precise specifications and tolerances.

VDI 3400 vs. Other Major Textures

In addition to SPI finish standards, there are other major texture standards used globally, such as Mold-Tech and Yick Sang textures. This section will compare VDI 3400 with these texture standards, highlighting their key differences and applications.

VDI 3400 vs. Mold-Tech Textures

Mold-Tech, a US-based company, offers custom texturing services and a wide range of texture patterns. Here are the key differences between VDI 3400 and Mold-Tech textures:

1. Texture Variety

a. VDI 3400: Standardized roughness grades, focusing on surface roughness.

b. Mold-Tech: Extensive library of custom texture patterns, including geometric, natural, and abstract designs.

2. Flexibility

a. VDI 3400: Limited to 45 standardized grades.

b. Mold-Tech: Highly customizable, allowing for unique and complex texture designs.

3. Application Areas

a. VDI 3400: Widely used in automotive injection molding, aerospace, and consumer electronics industries.

b. Mold-Tech: Primarily used in the automotive industry for interior and exterior components.

Conversion table between VDI 3400 and Mold-Tech textures:

VDI 3400 Grade | Mold-Tech Texture |

18 | MT 11010 |

24 | MT 11020 |

30 | MT 11030 |

36 | MT 11040 |

42 | MT 11050 |

*Note: The conversion table provides approximate matches based on surface roughness. Always consult with Mold-Tech for specific texture recommendations.

VDI 3400 vs. Yick Sang Textures

Yick Sang, a Hong Kong-based company, offers a wide range of texturing services and is popular in China and other Asian countries. Here are the key differences between VDI 3400 and Yick Sang textures:

1. Texture Variety

a. VDI 3400: Standardized roughness grades, focusing on surface roughness.

b. Yick Sang: Extensive library of custom texture patterns, including geometric, natural, and abstract designs.

2. Flexibility

a. VDI 3400: Limited to 45 standardized grades.

b. Yick Sang: Highly customizable, allowing for unique and complex texture designs.

3. Application Areas

a. VDI 3400: Widely used in automotive, aerospace, and consumer electronics industries.

b. Yick Sang: Primarily used in the consumer electronics and household appliance industries.

Conversion table between VDI 3400 and Yick Sang textures:

VDI 3400 Grade | Yick Sang Texture |

18 | YS 8001 |

24 | YS 8002 |

30 | YS 8003 |

36 | YS 8004 |

42 | YS 8005 |

*Note: The conversion table provides approximate matches based on surface roughness. Always consult with Yick Sang for specific texture recommendations.

Case Studies:

1. An automotive manufacturer chose Mold-Tech textures over VDI 3400 for their car interior components due to the wide range of available texture patterns and the ability to create custom designs that aligned with their brand identity.

2. A consumer electronics company selected Yick Sang textures over VDI 3400 for their smartphone casings because of the extensive library of unique texture patterns and the flexibility to develop custom designs that differentiated their products in the market.

Advanced Techniques and Innovations

Latest Developments in VDI 3400 Texturing

As manufacturing technologies continue to evolve, new innovations in texturing techniques are emerging to enhance the application of VDI 3400 standards. Some of the latest developments include:

1. Laser Texturing

a. Laser texturing technology allows for the creation of intricate and precise surface textures on mold surfaces.

b. This process offers high flexibility in design and can produce complex patterns that are difficult to achieve with traditional methods.

c. Laser texturing can be used to create VDI 3400 textures with improved consistency and repeatability.

2. 3D Printed Textures

a. Additive manufacturing techniques, such as 3D printing, are being explored for creating textured mold inserts.

b. 3D printed textures offer the ability to produce complex geometries and customized patterns, expanding the design possibilities for VDI 3400 textures.

c. This technology can reduce lead times and costs associated with traditional texturing methods.

Future trends in mold texturing include the integration of smart technologies, such as IoT (Internet of Things) and machine learning, to monitor and optimize the texturing process in real-time. These advancements will enable manufacturers to achieve higher levels of precision, consistency, and efficiency in applying VDI 3400 textures.

Case Studies and Real-World Applications

Several industries have successfully implemented VDI 3400 textures in their products, demonstrating the versatility and effectiveness of this standard. Here are two case studies:

1. Automotive Interior Components

a. An automotive manufacturer applied VDI 3400 textures to their car dashboard and door panels to enhance the visual appeal and tactile feel of the interior.

b. By using VDI 24 and VDI 30 textures, they achieved a consistent and high-quality finish that met their design requirements and customer expectations.

c. The implementation of VDI 3400 standards helped streamline their production process and reduce the need for manual finishing operations.

2. Medical Device Housings

a. A medical device company utilized VDI 3400 textures for their device housings to improve grip and reduce the risk of slippage during use.

b. They selected VDI 27 and VDI 33 textures based on their material properties and the desired surface roughness.

c. By adhering to VDI 3400 standards, they ensured consistent texture quality across multiple production batches and met the strict hygiene and safety requirements of the medical industry.

These case studies highlight the benefits of using VDI 3400 textures in real-world applications, including improved product quality, enhanced user experience, and streamlined manufacturing processes.

Advances in Measurement Technology

Recent technological developments have significantly improved the accuracy and efficiency of surface finish measurements, particularly for VDI 3400 textures. Some of these advancements include:

1. Non-Contact Measurement Systems

a. Optical profilers and 3D scanning technologies enable non-contact measurement of surface textures, reducing the risk of damage to the mold surface.

b. These systems provide high-resolution 3D data of the surface topology, allowing for more comprehensive analysis and characterization of VDI 3400 textures.

2. Automated Measurement Solutions

a. Automated surface measurement systems, equipped with robotic arms and advanced sensors, can perform rapid and precise measurements of large mold surfaces.

b. These solutions reduce the time and labor required for manual measurements and minimize the potential for human error.

The integration of AI and machine learning algorithms in surface finish measurement systems offers exciting possibilities for the future. These technologies can:

l Automatically recognize and classify VDI 3400 texture grades based on measured data

l Identify and flag anomalies or defects in the surface texture

l Provide predictive insights into mold performance and maintenance requirements

By leveraging these advanced measurement technologies and AI-driven analytics, manufacturers can significantly enhance the accuracy, efficiency, and reliability of surface finish measurements for VDI 3400 textures.

Conclusion

The VDI 3400 surface finish standard has revolutionized the manufacturing industry, offering a comprehensive and reliable method for achieving consistent, high-quality surface textures. Throughout this guide, we've delved into the numerous benefits and applications of VDI 3400, showcasing its versatility across sectors such as automotive, aerospace, consumer electronics, and medical devices.

As we look to the future, it's clear that VDI 3400 will continue to play a pivotal role in surface texturing, evolving alongside cutting-edge manufacturing techniques. With the advent of innovative texturing methods and advanced measurement systems, the possibilities for creating unique and functional surface finishes are virtually limitless.

Moreover, the integration of AI-driven analytics and automated solutions holds immense potential for streamlining the surface finish standardization process. By harnessing the power of these technologies, manufacturers can achieve unprecedented levels of precision, efficiency, and quality control.