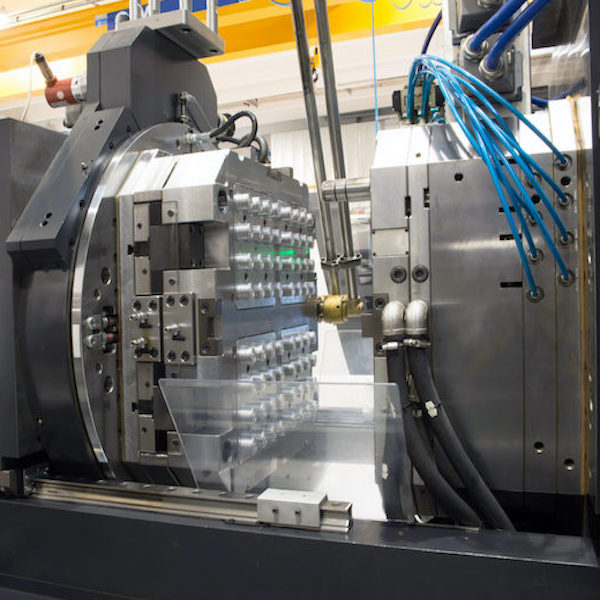

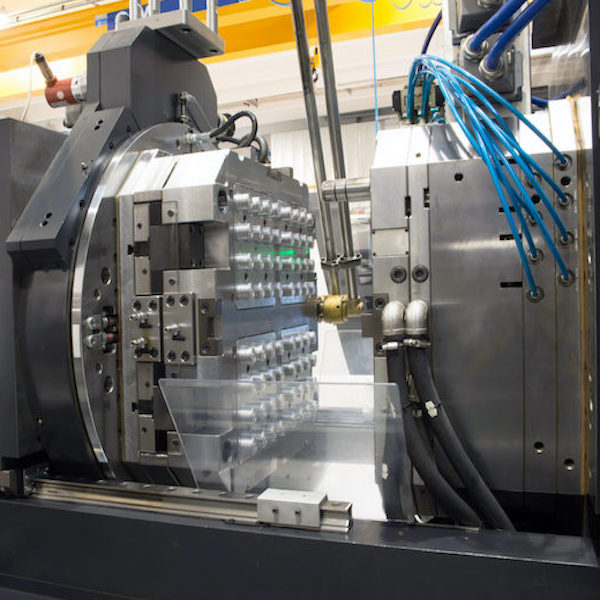

Injection molding is a key technology in modern manufacturing and is widely used in the production of various plastic products. Injection molding machines and auxiliary equipment play a vital role in injection molding, and their performance and efficiency directly affect product quality and production costs.

This guide aims to provide you with comprehensive knowledge of injection molding machines and auxiliary equipment, covering the types of injection molding machines, working principles, injection molding processes, auxiliary equipment selection, maintenance, and solutions to common problems.

What is an Injection Molding Machine?

An injection molding machine (also known as an economy press) is a device that will help you to create plastic items. The operational principle of injection molder works as follows: the plastic substances are first heated till they reach melting point, then the liquefied plastic is pumped into a die cavity under extremely high pressure. Upon cooling and hardening, the necessary plastic component is produced. Quantitative injection molding machines are capable of manufacturing identical plastic parts of given dimensions and contours by continuous repetition of the cycle.

Key components of injection molding machines

An injection molding machine consists of three main parts that work together seamlessly to produce high-quality plastic products. Let's examine each component in detail:

Injection unit

The injection unit serves the function of heating and mixing the pelletized plastic material and injecting the fluid into the site of the mold.

There are a number of elements which include hoppers, screw barrels as well as nozzles.

Inside the barrel, a helical rotating shaft is fitted to rotate which serves to melt, combine and feed the plastic samples for further ejection within the mold.

Compaction Unit

This particular unit is used for opening and closing the mold, and it also provides sufficient closing pressure during injection so that the mold cannot open.

Some of its constituent parts include: the platens, tie bars, guidance system and clamping cylinders.

The amount of clamping force depends on the injection molding machine model and size of the injected products.

Control System

Since it regulates and supervises most processes undertaken in injection molding, the control system may be likened to the “nervous system” of the injection molding machine.

For example, it controls the injection speed, pressure, temperature, time and other variables to ensure process and product quality.

Most modern injection molding machines are designed with touch screen controls and a PLC structure that is easy to operate and ensures high levels of operation efficiency.

Classification Of Injection Molding Machines

Injection molding machines can be divided into three categories according to their mode of drive. Each of them has its own peculiarities and fields of application:

Hydraulic Injection Molding Machines

The hydraulic systems power the injection as well as the clamping units in hydraulic injection molding machines.

These machinery frequently possess a greater injection and clamping force, so they are ideal for producing big and bulky parts.

Though the hydraulic systems have slower dynamic responses and suffer more thermal losses, the prices on such machines are much lower.

Electric Injection Molding Machines

Instead of hydraulic cylinders, all the injection and clamping components in electric injection molding machines are actuated by servo motors.

Due to having high precision and being fast in operation and low in noise, these are considered quite suitable in the production of complex and elaborate parts made of plastic.

Electric injection molding machines consume less power but the cost of these machines is high.

Hybrid Injection Molding Machines

The hybrid injection molding equipment is designed to combine the advantages offered by the hydraulic and the electric technologies.

They typically have an electric powered injection unit, while the clamping unit is hydraulic.

This design incorporates amazing speed, accuracy and performance with minimal energy and cost in contrast with fully hydraulic machines.

Injection Molding Process

The plastic injection molding process transforms raw plastic materials into precision-engineered parts through a systematic sequence of operations. Here's a detailed examination of the process and key optimization factors:

Understanding the Injection Molding Cycle

The overall process of injection molding is completed after four important elements are incorporated into the system. These elements are responsible for the quality of the end product and the productivity of the process:

1. Plasticization of the Material & Injection

The material in the form of granules is loaded into the injection unit from the material hopper.

The injection screw system operates at different temperatures to melt and mix the material.

Molten plastic at high pressure is injected into the mold cavity at controlled velocity.

2. Mold Closing & Filling of Cavity

Tonnage is applied to the clamping unit of the injection molding machine to close and lock the mold halves.

Hydraulic and electric cycled clamp systems provide the same force accurately during injection of the material.

Too much pressure can lead to flash but optimimum pressure of injection enables filling up the cavity completely.

3. Part Cooling and Material Solidification

Cooling rates are maintained by the mold temperature control systems in operation

Cooling timers are specific to the working material and help increase the efficiency of the cycle.

Controlled solidification helps in avoiding bending while maintaining the sizes of the products.

Innovative designs of cooling channels shorten the cycle time.

4. Part Removal and Cycle Rest

Finished parts are removed by automated ejector systems

Increase in speed of quick mold opening enhances productivity

Automated systems for placement and removal of parts enable uninterrupted work

Cycle cuts down the cost of production

Critical Process Parameters

Effective process control in injection molding utilizes three main components materials, molds, and machine adjustments all of which need careful specification and regulation:

Material Selection and Their Characteristics

The types of thermoplastic materials used in the molding process are so unique that they can be said to define the process. The viscosity of the material influences the injection pressure that will be required, while the thermal properties affect how optimally times for cooling will be controlled. If a shrinkage rate for a certain material is known, the dimensions of the parts, and the need for compensation of the mold, can be very closely defined.

Precision Mold Engineering

Manufacturer of effective molds involves multiple components such as runner systems, gates, and cooling channels. The design of the form has to contain proper the system of vents and drafted angles to allow easy removal of the parts without faults.

Adjustment of Machine Control Parameters

Precision settings of the parameters of the injection molding machine are required at every stage of the molding cycle. This also means the profiles of the injection speed are controlled, holding pressures, barrel zone temperature are all optimized for the best results. Other important parameters include the control of the temperature of the mold, the back pressure, and the timing of the screw recovery, which are crucial to the quality of the parts produced.

Support Machinery for Injection Molding

The operations involving injection molding of plastics do not only entail the injection molding machine but are also supplemented by a range of different supportive machineries. These auxiliary equipment pieces play a key role in the enhancement of the hot melt extrusion process by increasing its efficiency, quality, and consistency.

Role of auxiliary machinery in injection molding processes

Auxiliary machinery has four main roles in injection molding processes. First, it prevents the deterioration of the raw materials by providing the correct handling and preparation. Second, it provides adequate heat control of the mold, the heat source as well as of the molten plastic in the process of molded plastic production. Third, it modifies the processes and techniques used in production so that less labor is incurred and greater production is achieved. Lastly, it helps in maintaining the same quality of the part by reducing the variations in the processes and the human factors.

Types of support machinery

There are three major categories of support equipment that are essential for the effective functioning of injection molding operations and they include: material handling systems, temperature control equipment, and automation systems. Now let us delve into each of these categories in detail:

Material handling equipment

The distinction and their functions all relate to Material handling equipment; that is in a way that Mobile cranes are used to store, transport and prepare the plastic raw materials before main component, i.e. injection molding machine, is used.

Hopper loaders: Hopper loaders are used for automatic feeding of plastic pellets or granules to the injection molding machine hoppers. Also, they help in preventing backflow of the materials and they can be fitted with additional features, for instance, material blending and blending ratio controls.

Dryers and dehumidifiers: Most of modern plastics are hygroscopic meaning they will tend to suck moisture from the atmosphere. At least dry the pellets and dehumidifier nozzles help in this respect before entering the injection molding machine to avoid defects like s/w, lower mechanical properties, damage of the materials.

Granulators and shredders: Granulators and shredders are employed in the Internal Reinforced Plastics fabrication process to collect excess plastic materials, such as sprues, runners and scrap parts, so that they can be reused as raw materials. They assist in cutting down the material waste and the overall injection molding cost by enabling the use of plastic again in the same injection molding process.

Temperature control units

Temperature control units play a critical role in controlling the temperature of the mold as well as the molten material to avoid inconsistencies when it comes to cooling and solidification.

Water chillers: Water chillers serve the purpose of passing water through the cooling channels of the mold to freeze the mold and the resin inside. Aided with these, it becomes easier to retain the optimum temperature of the mold hence increasing the quality of the molded parts while at the same time decreasing the cycle time.

Oil heaters: Mold oil heaters are employed to bring the mold’s temperature up to working levels before injection is performed. These assist in even and precise heat application which in turn helps in avoiding problems like cold slugs or improper filling.

Robots and automation systems

Robotic and automated systems serve to eliminate manual and repetitive work at nearly all processes of injection molding cycle, be it removal of parts or even packing the products.

Sprue pickers: Sprue pickers are conventional industrial robots which take out the sprue from the mold after every complete cycle. This is done in order to decrease the cycle times and the reliance on human skills.

Part removal robots: Part removal robots, also known as takeout robots, transfer the molded elements from the mold cavity to a waiting conveyor or collection bin. They are designed as versatile tools that can process parts of different configurations and dimensions, there by enhancing efficiency and uniformity.

Automated packaging systems: Automated packaging systems, such as box fillers or bag sealers, are used for the final touch on the products by packing them in boxes or wardrobes in readiness for storage or shipment. They aid the production process after molding and help save on expenses for labor.

Maintenance and Troubleshooting

It is essential to perform proper maintenance and troubleshooting in order to keep injection molding machines and auxiliary machines in good working condition. Introduction of periodic maintenance routines aids in avoiding equipment failures, prolongs serviceable life of the equipment and maintains product quality during machining cycles. Maintenance performed when a given trouble is localized serves to shorten losses in production cycles and hence reduce waste. In order to maintain a high level of performance of the injection molding set, routine care of the appliances must be carried out according to the schedule of the following tasks:

Cleaning and lubrication

The hopper, barrel, and nozzle of the injection molding machines should be cleaned on a regular basis to avoid any contamination or degradation of materials.

To avoid friction and ensure proper functioning of moving components, tie bars, ejector pins, and sliding surfaces should be greased regularly.

Separation of molds should be cleaned with care devoid of any dirt or remnants that may impair the quality of the parts or lick damaging the surfaces of the moulds.

Wear part replacement

To ensure that there is uniform output and to avoid unforeseen breakdowns, it is important to periodically examine and change, for instance, the barrel heaters, thermocouples, and nozzle tips.

Observe the state of the screw and tapered barrel and if necessary replace for proper plasticizing and injection of materials.

Inspect for wear and tear or damage and replace parts of mold such as cores, cavities, and ejector pins to ensure quality of molded parts and avoid damages on the mold itself.

Calibration and adjustment

Make sure that temperature controllers, pressure sensors and other measuring devices are periodically calibrated in order to maintain their accuracy as well as control.

Enhance processes in relation to each material and mold combination by altering machine parameters including but not limited to injection speed, holding pressure as well as cooling time.

Confirm that the molding platens and tie bars are properly aligned to avoid uneven wear across the tie bars and ensure that the clamping force is evenly distributed.

Common issues and troubleshooting tips of Injection Molding and Support Machines

Even if it is quite common to keep the machinery in good order using standard practices, certain problems tend to occur when performing the injection molding operations. Addressing common molding defects can be accomplished through a series of steps as follows:

Burn marks and discoloration

Burn marks and Materials discoloration generally occur due to overheating of the materials or excessive shear stress on the materials during the process. To mitigate this problem, process parameters should be adjusted by lowering barrel temperatures and injection speeds with good molding venting for gas removal. Also control material residence time and check deflation provision to avoid air pockets or gases during cavity filling.

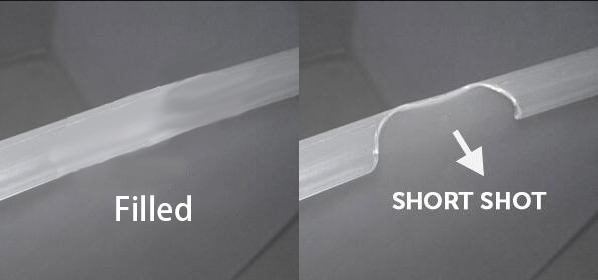

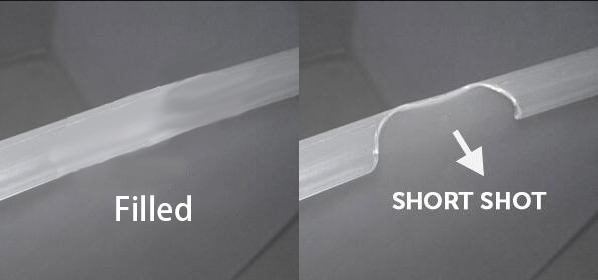

Short shots and incomplete filling

Short shots of the parts meaning parts or sections are left unfilled or filled with a material flow or pressure inadequacy. These defects can be corrected by the appropriate modification of limitations of parameters: the injection pressure must be increased, and the injection speed must be increased, the shot weight must be checked, as well as heated the mold. Clogged nozzles and runner systems should be checked on a regular basis in order to avoid such materials flow problems.

Flash and overflows

Presence of excess material at the parting line or around ejector pins indicates pressure imbalance in the process or wear and tear of the molds. Flash can be contained within above limits by controlling the injection parameters: injection pressure, shot size and maintenance of the holding pressure system. In order to preserve proper sealing of the molds, wear and tear of parts related to parting line surfaces and ejector pins must be addressed through frequent maintenance of the molds.

Warping and dimensional instability

Diverse rates of cooling and the resultant internal stresses cause warping of the part as well as dimensional variations. Achieve dimensional stability by optimizing the design and operation of the cooling system to its fullest potential: the configuration of cooling channel orifices, the modifications of cooling time settings, and the preservation of consistent temperature of molds. The design should also take into account the location of the gates, thickness taper transitions and their effects on differential shrinkage and stresses.

Advantages of Injection Molding

Great output and productivity

Currently available injection molding machines are capable of very high throughput level owing to cycle optimization and in-built automation. High-speed injection molding systems are capable of producing thousands of parts within the hour, where cycles could last from seconds to minutes depending on the complexity of the part played. There are also multi-cavity molds which further distribute this advantage of increasing production capacity, allowing the geometrically identical part to be molded several times at once. Because of this, advanced process control systems ensure that the parameters of the cycles remain ‘on the mark’ while ‘off the mark’ amounts of materials are eliminated via precise shot control and optimization of runners.

Repeatability in molded parts

Injection molding technology ensures very makeable dimensional tolerances and near perfect part repeatability. Computer controlled injection speeds, pressure profiles, temperature zones among other critical parameters aids in the maintaining of the material flow and packing of the part. Nowadays machines work with dimensional accuracies around ±0.1mm and complex and state of the art quality assurance systems intervene in the process to safeguard important dimensions of the part. It is this precision that allows constructing geometries of such complexity aimed for use in the areas where medical, automotive engineering and aviation industries belong.

Broad Spectrum of Material Choices

A major advantage of the injection molding process is the ability to work with many types of thermoplastic materials, each with unique performance properties. Acceptable materials could range from low-cost resins such as polyethylene and polypropylene to expensive performance engineering plastics like PEEK or PPS and so on and the right material can always be favorable for a given use. Upgraded version of the injection molding machines are capable of processing reinforced composites, engineered resins and other specialty additives as a result parts fabricated have improved mechanical properties, high heat, and chemical resistance.

Freedom and complexity in shaping

Some latest injection molding procedures allow manufacturing parts with very complex geometries for which other methods would be impractical. Advanced mold designs include features such as undercuts, internal threads, and living hinges all present in a single part. Multi-material injection molding allows for parts with distinctly different material properties to be manufactured while in-mold decoration and assembly minimize the need for secondary operations. Moreover, gas assisted and foam injection moulding techniques achieve lightweight and optimal designs without compromising on part integrity.

Conclusion

Regardless of the manufacturing process used for making plastics, all today’s plastic processing industries must have injection molding machines and their auxiliary equipment. Such machines range from fast operating hydraulic presses to well engineered electric injection molding mechanization, offering high volumes of output and quality of the molded parts. Knowledge of all process parameters, reasons for the choice of certain classes of supporting machine and the guidelines for their operation and repair allow achieving maximum efficiency in production processes.

TEAM MFG provides injection molding services for plastic parts including assistance in selection of equipment for molding processes, customizing existing technologies and troubleshooting. Get in touch with our engineers who will offer tailor made injection molding services to meet your manufacturing needs.

Reference Sources

Injection Molding Machine

Injection Molding

FAQs

What are the main differences between plastic injection molding and metal injection molding machines?

When it comes to metal injection molding (MIM) machines, they use the higher temperatures and pressures than that of plastic injection molding machines. Furthermore, MIM machines require additional special feeders and a debinding machine for the usage of metallic powders and for the removal of binders once molding is done.

Can a desktop injection molding machine be used to perform injection molding for small scales only?

Certainly, The engineers and designers use small optical injection machines called desktop injection molding machines, also referred to as benchtop or micro injection molding machines. These machines are meant to produce small parts of lesser volumes than full-size injection molding machines offer.

What is an injection molding workbench kit and how does it aid in product development?

An injection molding workbench kit is a self-explanatory piece of equipment designed for tinkerers which typically fits the profile of a desktop injection molding machine and few other amenities. Generally, they help designers and engineers to rapidly create and evaluate injection molded parts, thus enabling quicker turnarounds to market with lower expenses.

What support machinery is appropriate for my injection molding operation?

While selecting support machinery for your injection molding operation, some of the factors you need to look at include the anticipated production volume and the part requirements in terms of materials, geometry, and degree of automation. Talk to equipment providers or plant specialists about the ideal auxiliary equipment for your particular application.

How helpful is the evaluation of safety risks in using an injection molding machine template?

A risk assessment template for injection molding aids in hazard identification, risk evaluation, and risk control. The ability to risk assess activity hazards is essential in most modern manufacturing environments. In fact, it is almost a pre-requisite in any activity that maintains a healthy and safe working environment. The use of an extensive and complete risk assessment of injection molding template enables manufacturers to create a healthier environment and comply with the safety standards of the prevailing industry.