Ever wonder how precision plastic parts are made with such accuracy? The secret lies in the injection molding nozzle. This crucial component ensures molten plastic flows smoothly from the machine’s barrel into the mold. Without it, achieving consistent quality in molded products would be impossible.

In this comprehensive guide, we'll dive deep into the world of injection molding nozzles. You'll learn about their various types, key characteristics, common defects, and maintenance best practices.

General Introduction of Injection Molding Nozzles

Injection molding nozzles are key to shaping and directing molten plastic from the machine into the mold. But not all nozzles are created equal. One type, in particular, stands out for its flexibility and efficiency—modular injection molding nozzles.

What Are Modular Injection Molding Nozzles?

Modular nozzles are designed with multiple interchangeable parts. These parts allow the nozzle to easily connect to various machines and molds. Unlike single-piece nozzles, which are limited to one setup, modular designs offer far more versatility.

Key Advantages of Modular Designs

Flexibility: The nozzle body can work with multiple injection barrels and molds by simply swapping out components.

Cost-Effective: Modular nozzles save on long-term costs, as you only replace individual parts instead of the whole nozzle.

Customizability: Each part of the nozzle can be tailored to fit specific machine and mold requirements. This adaptability ensures compatibility with a wide range of manufacturing setups.

How Modular Nozzles Work

The nozzle’s back end connects to the injection barrel, and the front interfaces with the mold’s sprue bushing. You can easily swap these sections to fit different machines and molds, making them a perfect fit for dynamic production environments.

By using modular nozzles, manufacturers enjoy smoother operations and reduced downtime when changing machines or molds. It's a smart choice for companies looking to optimize their production lines.

Types of Injection Molding Nozzles

Injection molding nozzles come in various designs, each suited for different applications and requirements. Let’s explore some of the most common types used in the industry today.

Screen-Pack Nozzle Filters

What Is a Screen-Pack Nozzle Filter?

Screen-pack nozzle filters are simple yet effective tools for capturing contaminants in the molten plastic stream. As the plastic flows through the nozzle, it passes through a metal disk with small holes. These holes filter out particles that might otherwise damage the mold or affect product quality.

Function: They trap contaminants in the melt, ensuring cleaner production.

Benefits: Screen-pack filters are low-cost and have a straightforward design, making them easy to install and use.

Drawbacks of Screen-Pack Nozzles

Pressure Drop: The small holes in the filter create resistance, causing a noticeable pressure drop in the flow, which can impact the injection process.

Frequent Cleaning: As contaminants build up, they clog the holes, reducing the flow even more. This requires regular cleaning, which can interrupt production.

Gap-Filter Nozzles (Edge Filter Nozzles)

What Is a Gap-Filter Injection Molding Nozzle?

Gap-filter nozzles, also known as edge filters, solve the pressure drop issue by offering a larger flow area. Instead of forcing the plastic through tiny holes, these nozzles direct the melt over thin walls between grooves. This design filters the melt more efficiently with less resistance.

Design: They provide a larger flow area, reducing pressure drop compared to screen-pack nozzles.

Why It’s Better: They allow the melt to travel through wider gaps, which results in less pressure buildup and smoother flow.

Advantages of Gap-Filter Nozzles

Longer Between Cleanings: Since the gaps are wider, more contaminants can be trapped without immediately affecting performance.

Lower Pressure Increase: Even as contaminants accumulate, the larger flow area helps maintain lower pressure, extending the operational time.

Mixing Nozzles

What Are Mixing Nozzles in Injection Molding?

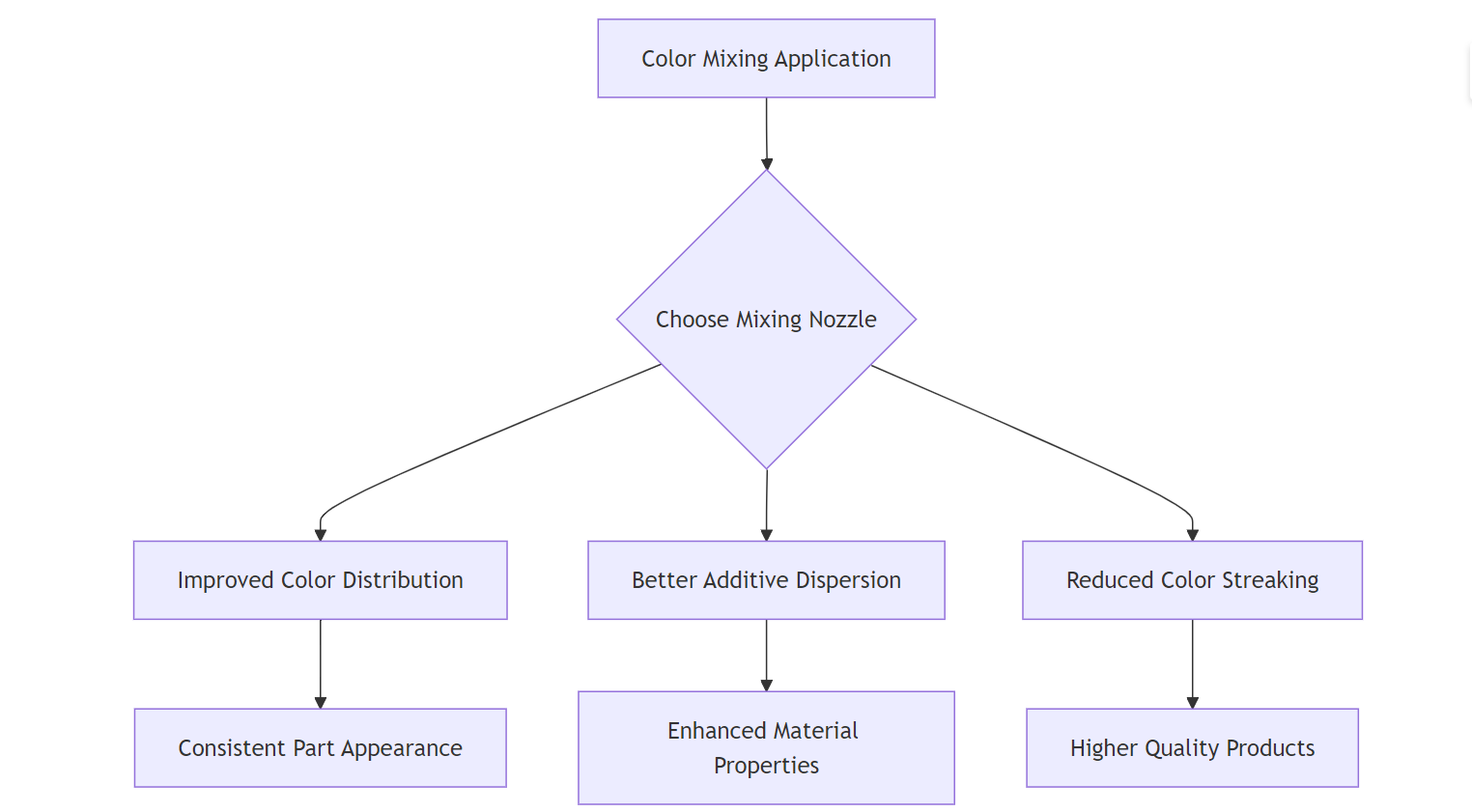

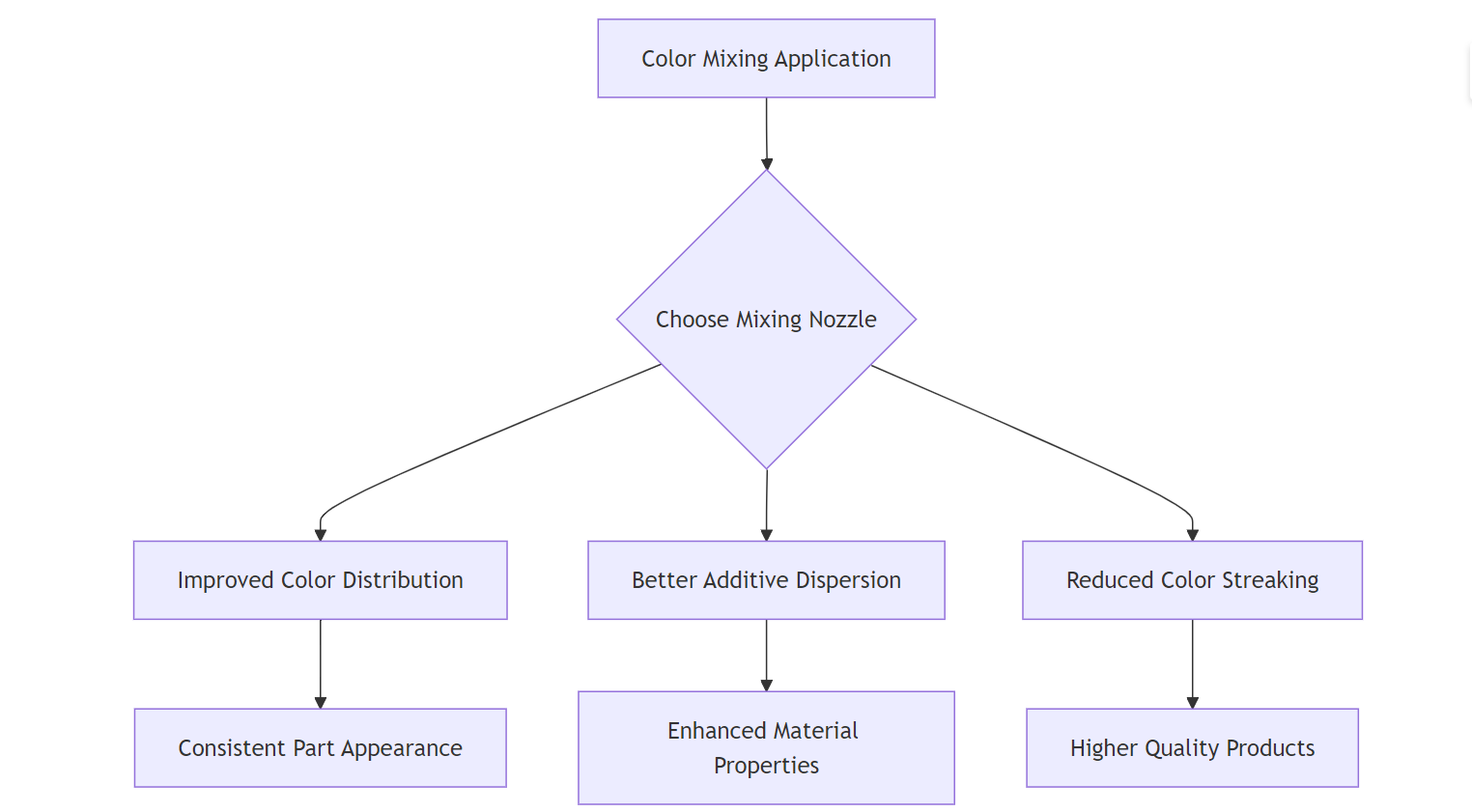

Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the molten plastic. They mix the material as it passes through the nozzle, creating a homogeneous blend that improves the quality of the final product.

Types of Mixing Nozzles

Benefits of Mixing Nozzles

Better Temperature Dispersion: By constantly moving the melt, these nozzles help balance temperature differences within the material.

Reduced Shear Stress: Triple-action nozzles minimize stress on sensitive materials like PET, which can degrade under high shear.

Shut-Off Nozzles

What Are Shut-Off Nozzles in Injection Molding?

Shut-off nozzles are designed to stop the flow of molten plastic between shots, preventing drooling or leakage. These nozzles are essential in multi-shot molding applications where precise control over the melt is crucial.

How Shut-Off Nozzles Work

Automatic Shut-Off: Many modern nozzles use spring-operated systems that automatically open or close based on pressure. This ensures safety and consistency without manual intervention.

Safety Features: Built-in mechanisms prevent over-pressurization, reducing the risk of damage or hazardous situations in case of machine downtime.

Common Problems with Injection Molding Nozzles and Solutions

Nozzle Leaks

What Causes Nozzle Leaks?

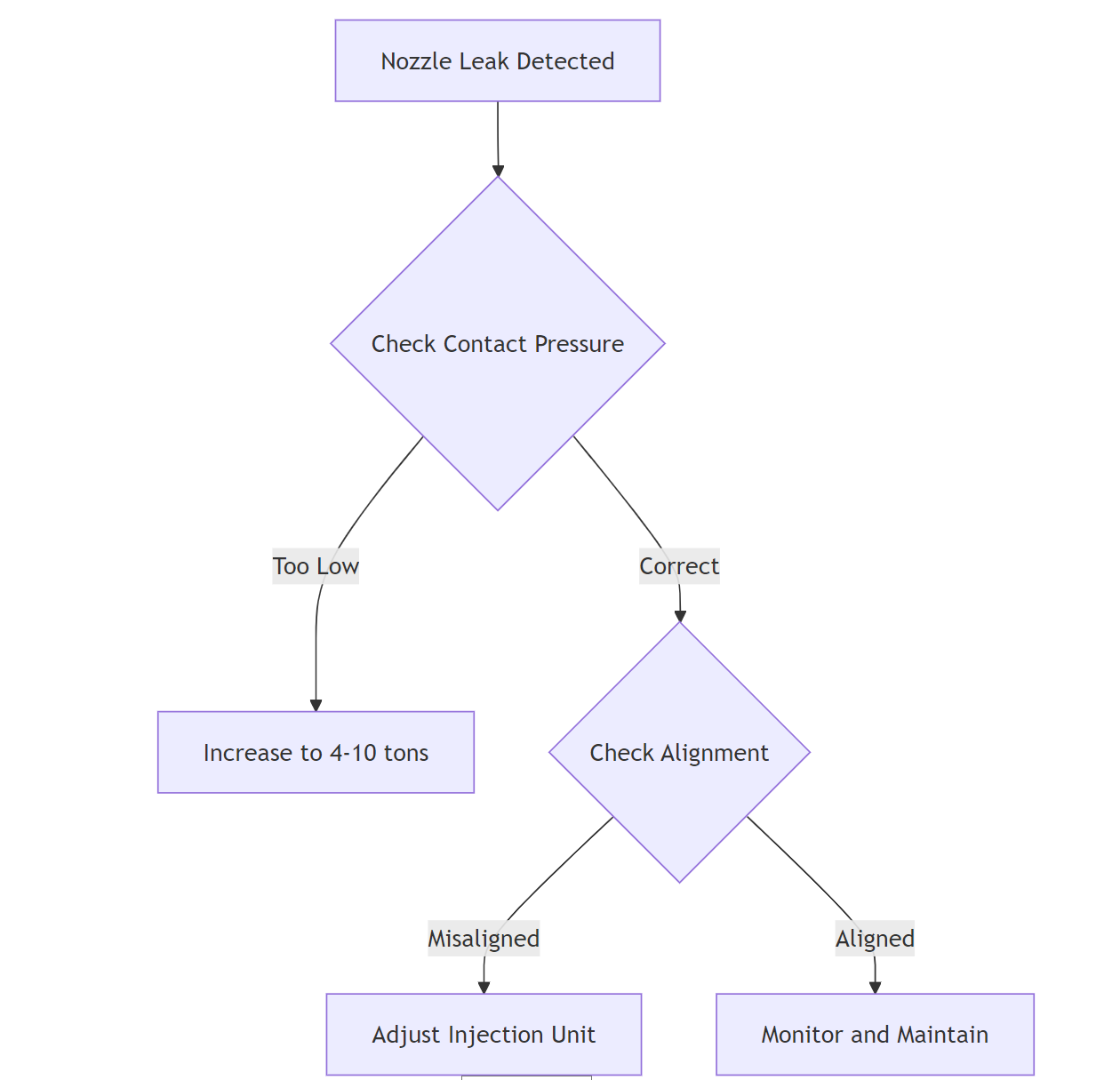

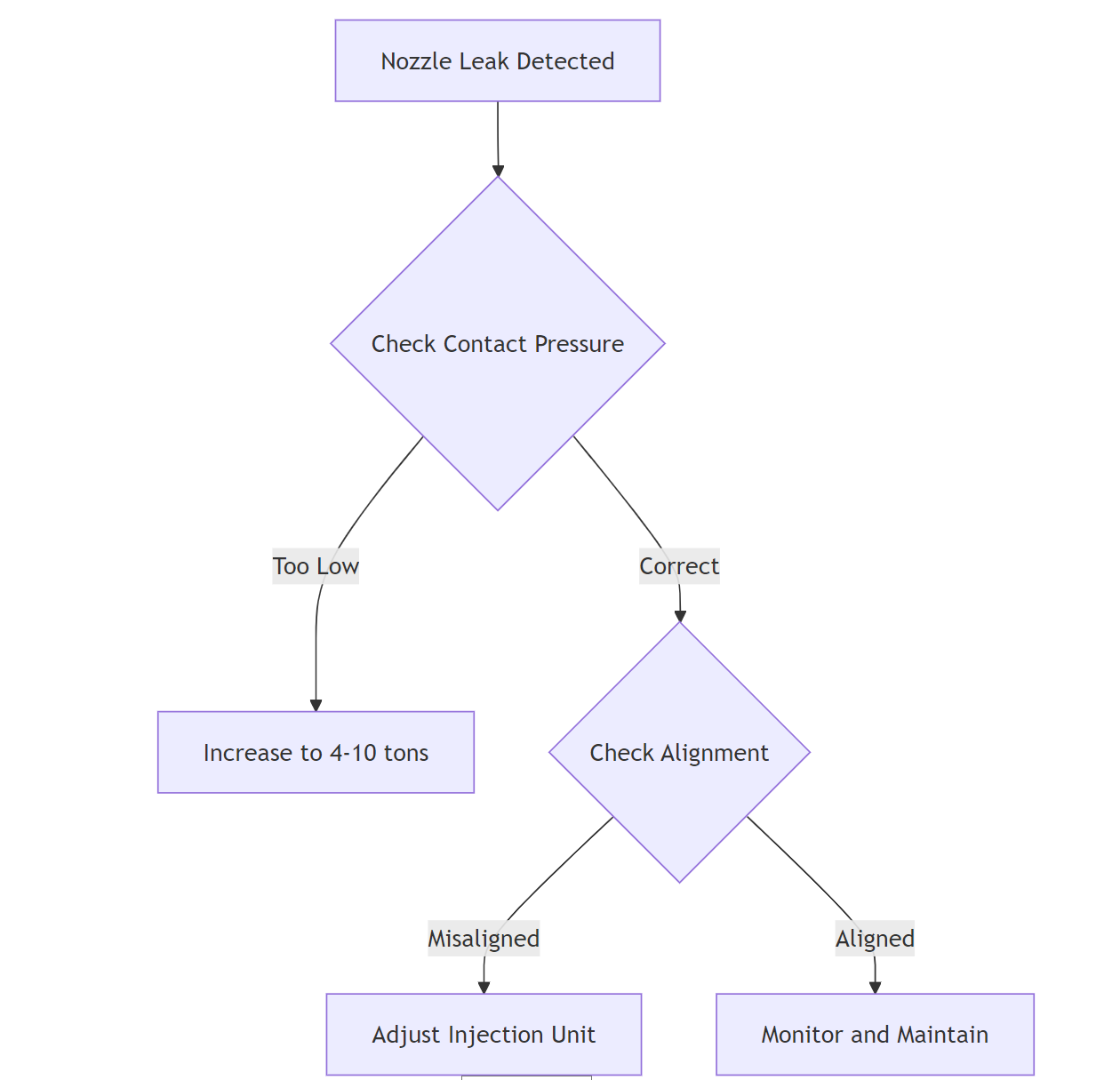

Low contact pressure: When the nozzle doesn't snug up tight enough against the sprue bushing, trouble brews.

Misalignment: If the injection unit and sprue bushing aren't perfectly in sync, leaks are bound to happen.

Solutions for Nozzle Leaks

Dial in that pressure: Aim for 4-10 tons of contact pressure. It's the sweet spot for a solid seal.

Check the alignment: Make sure your nozzle and sprue are a perfect match. It's like a dance – they need to move together.

Here's a quick visual to help you out:

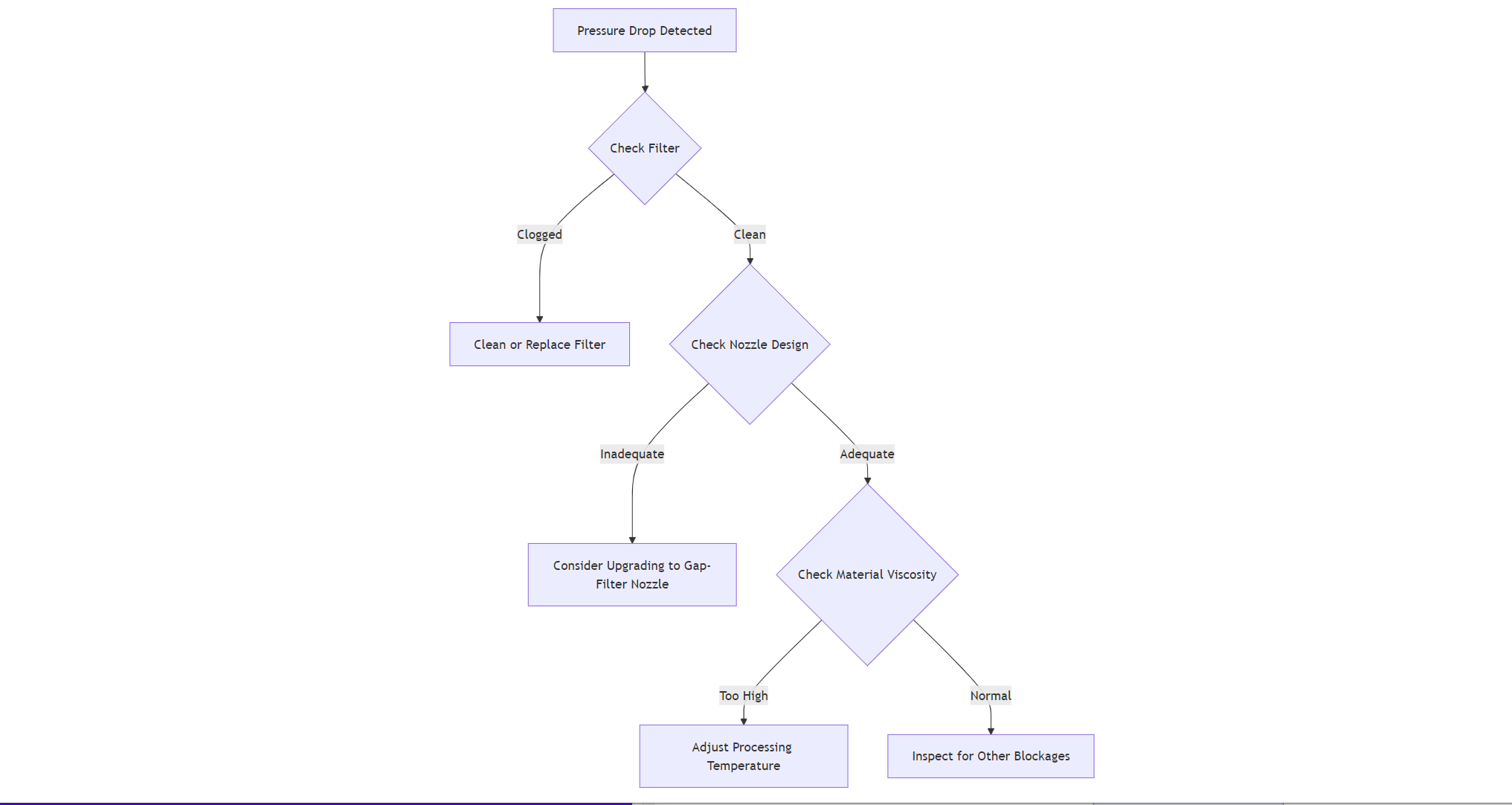

Pressure Drop in Injection Molding Nozzles

Pressure drop can sneak up on you. It's like trying to drink a thick milkshake through a tiny straw. Not fun, right?

Why Does Pressure Drop Occur?

The culprits are often:

How to Reduce Pressure Drop

Upgrade your hardware: Consider switching from screen-pack to gap-filter nozzles. They're like opening up a highway for your plastic to flow through.

Keep it clean: Regular maintenance is key. Think of it as giving your nozzle a spa day – it'll thank you with better performance.

Nozzle Tip Damage

What Causes Nozzle Tip Damage?

This damage can manifest as:

How to Prevent and Fix Nozzle Tip Damage

Stay on top of maintenance: Regular check-ups can catch issues before they become big problems.

Keep things aligned: A properly aligned sprue and nozzle tip will reduce unnecessary wear.

Know when to say goodbye: Sometimes, replacement is the best option. Don't be afraid to swap out damaged components.

Here's a handy table to help you track nozzle tip condition:

| Condition | Action Required |

| Minor wear | Monitor closely |

| Visible distortion | Plan for replacement |

| Burrs or gouges | Immediate replacement |

By keeping these tips in mind, you'll be well on your way to smoother injection molding operations. Remember, a little preventive care goes a long way in keeping your nozzles happy and your production flowing smoothly.

How to Choose the Right Injection Molding Nozzle for Your Application

Key Considerations When Selecting a Nozzle

When picking a nozzle, there are three main factors to keep in mind. They'll help you narrow down your options and find the best fit for your needs.

Material Compatibility

The type of plastic you're molding plays a big role in nozzle selection. Different materials have unique properties that require specific nozzle designs.

For high-temperature plastics like PEEK, consider nozzles made from heat-resistant alloys.

Fiber-reinforced materials might need more wear-resistant nozzle designs.

When working with shear-sensitive materials, choose nozzles that minimize shear stress.

Machine and Mold Compatibility

Ensuring your nozzle fits perfectly with your machine and mold is crucial. It's like a puzzle - every piece needs to fit just right.

Check the nozzle's thread specifications to match your injection molding machine.

Make sure the nozzle tip radius matches the sprue bushing to prevent leaks.

Consider modular nozzle designs for greater flexibility.

Flow Characteristics

Different nozzle designs affect melt flow and pressure in unique ways. Understanding these characteristics can help you optimize your molding process.

Here's a quick comparison of common nozzle types and their flow characteristics:

| Nozzle Type | Flow Characteristic | Best For |

| Standard | Moderate flow, moderate pressure drop | General purpose |

| Free-flow | High flow, low pressure drop | Large parts, fast cycles |

| Mixing | Enhanced material homogenization | Color changes, additives |

| Shut-off | Controlled flow, prevents drooling | Multi-shot molding |

Choosing a Nozzle Based on Application

For High-Precision Molding

When you're producing precision parts, consistent flow and pressure are key. It's like conducting an orchestra - every element needs to be in perfect harmony.

Opt for nozzles with precise temperature control.

Consider nozzles with built-in filters to ensure melt quality.

Evaluate nozzles for pressure consistency to maintain dimensional stability.

For Color Mixing and Additives

If you're working with color concentrates or other additives, mixing nozzles might be your best bet. They're like miniature blenders, ensuring even dispersion.

For High-Temperature Molding

High-temperature molding is like cooking in a volcano. You need equipment that can stand up to extreme conditions.

Choose nozzles with heat-resistant components, such as special alloys or ceramic linings.

Ensure the nozzle provides good temperature uniformity to prevent material degradation.

Consider nozzle designs with additional cooling features.

Maintenance and Troubleshooting for Injection Molding Nozzles

Regular Maintenance Tips for Injection Molding Nozzles

Cleaning and Inspection

Regular cleaning and inspection of your nozzles are like giving your car a tune-up. It keeps everything running smoothly and helps you catch potential issues before they become major problems.

For screen-pack and gap-filter nozzles:

Cool down the nozzle before cleaning.

Disassemble carefully, noting the order of components.

Use a brass brush or specialized cleaning solution to remove residue.

Inspect filter elements for damage or excessive wear.

Clean or replace filter elements as needed.

Here's a handy cleaning schedule to keep your nozzles in prime condition:

| Production Volume | Recommended Cleaning Interval |

| Low | Every 2-3 months |

| Medium | Monthly |

| High | Bi-weekly or weekly |

Preventing Wear and Tear

A little prevention goes a long way in extending the life of your nozzles. Think of it as giving them some TLC.

Regularly inspect nozzle tips for signs of wear or damage.

Check alignment between the nozzle and sprue bushing frequently.

Lubricate moving parts according to manufacturer specifications.

Monitor operating temperatures to prevent overheating.

Pro tip: Keep a maintenance log. It'll help you track wear patterns and predict when replacements might be needed.

Troubleshooting Common Nozzle Issues

Even with the best maintenance, issues can still crop up. Let's look at how to tackle some common problems.

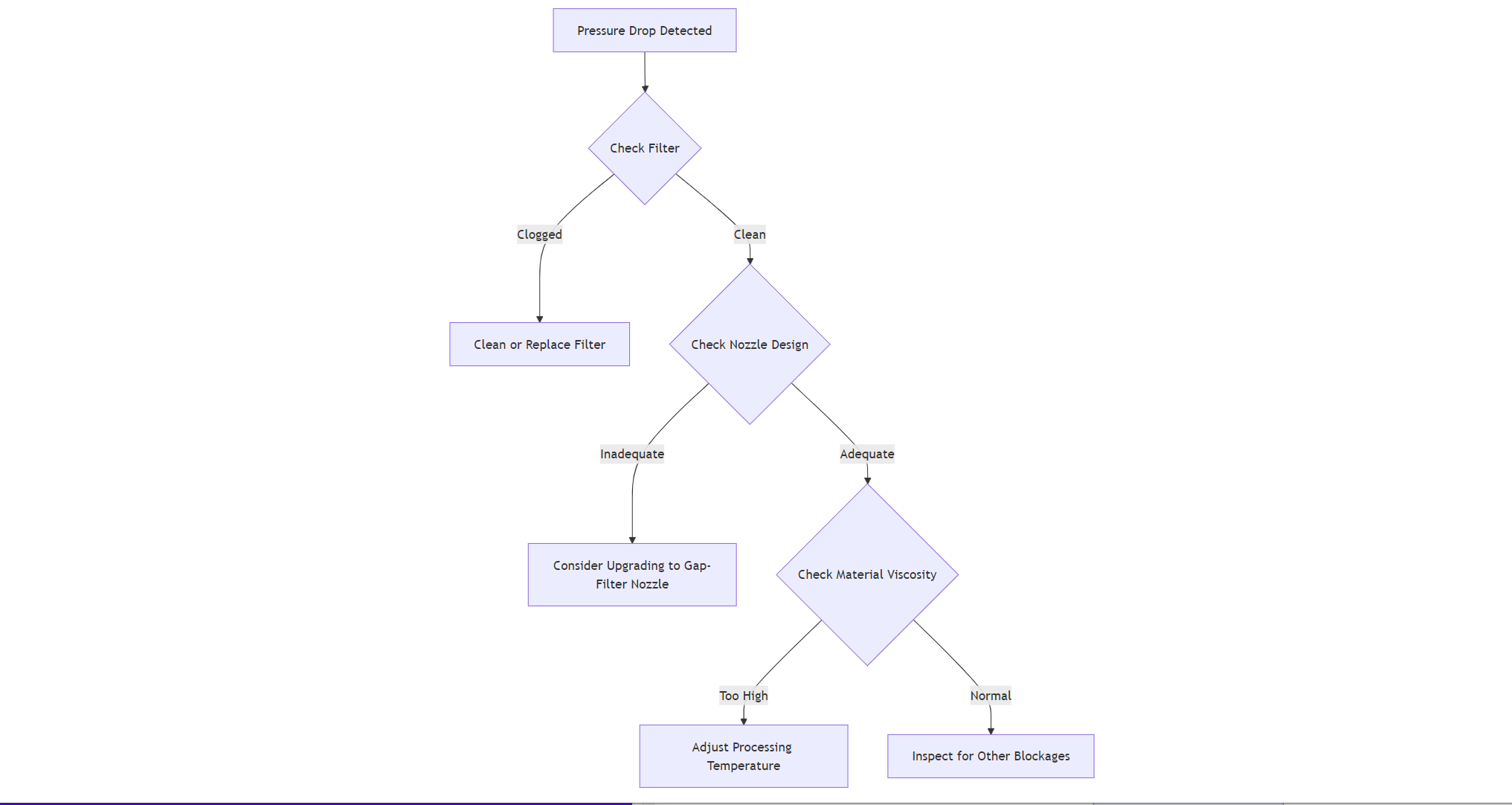

Pressure Drop Troubleshooting

Experiencing a pressure drop? It's like trying to drink a thick milkshake through a thin straw. Here's how to identify and resolve the issue:

Start by checking your nozzle filter. Is it clogged?

If the filter's clean, look at your nozzle design. Is it suitable for your material?

Consider upgrading to a gap-filter nozzle for better flow and less pressure drop.

Check your material viscosity. You might need to adjust processing temperatures.

Fixing Nozzle Leaks

Nozzle leaks can be messy and wasteful. Here's how to stop them in their tracks:

Check contact pressure between the nozzle and sprue bushing.

Inspect the nozzle tip and sprue bushing for damage.

If you spot damage, replace the affected components.

Ensure proper alignment between the injection unit and sprue bushing.

A little leak can become a big problem if left unchecked. Don't hesitate to address it promptly.

Innovations and Advancements in Injection Molding Nozzles

The world of injection molding is constantly evolving, with new technologies emerging to improve efficiency and product quality. Let's explore some exciting innovations in nozzle design that are revolutionizing the industry.

Purgeable Nozzle Filters

What Are Purgeable Nozzles?

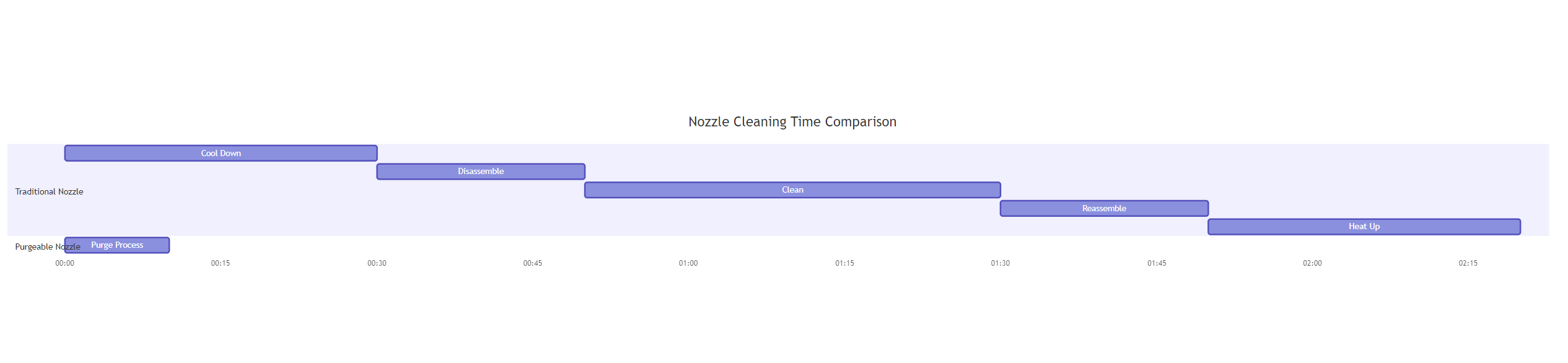

Imagine a self-cleaning oven, but for your injection molding nozzle. That's essentially what purgeable nozzles are all about. They allow for cleaning without the need for disassembly, saving time and reducing the risk of damage during maintenance.

Here's how they work:

The nozzle tip is designed to move forward slightly.

This movement creates a bypass channel.

When you purge, contaminants are forced out through this channel.

The nozzle is cleaned without ever being taken apart.

Advantages of Purgeable Nozzles

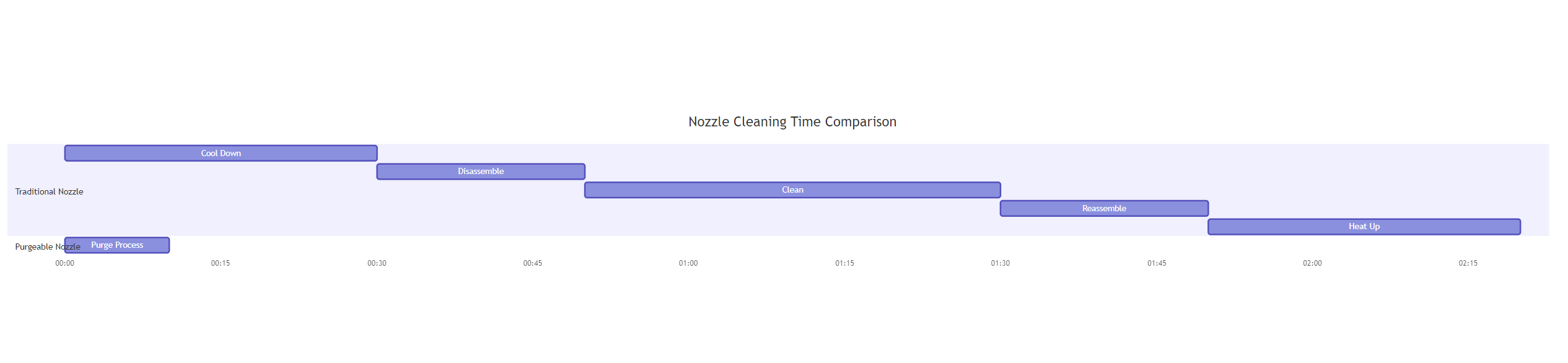

Minimized Downtime: With traditional nozzles, cleaning can take hours. Purgeable nozzles cut this down to minutes.

Increased Production Efficiency: Quick purging between cycles means more time for actual production.

Reduced Risk of Damage: Less handling during cleaning means less chance of accidental damage.

Improved Material Consistency: Frequent, easy cleaning leads to better quality control.

Let's visualize the time savings:

Advances in Nozzle Filtration

How New Filter Technologies Are Improving Efficiency

Modern nozzle filtration is all about balance - capturing contaminants without sacrificing flow. New designs are making this balancing act easier than ever.

Gap Filters: The Pressure Drop Heroes

Gap filters, also known as edge filters, are changing the game. They're like the superhighways of the nozzle world, allowing for better flow with less pressure drop.

Here's why they're so effective:

Larger filtration area compared to traditional screen packs

Melt flows over thin ribs instead of through tiny holes

Contaminants are trapped without significantly restricting flow

The result? You get cleaner material with less pressure loss. It's a win-win!

Handling More Contamination

Modern filters aren't just about reducing pressure drop. They're also getting better at handling contamination:

Increased dirt-holding capacity

Longer intervals between cleanings

Better retention of small particles

Let's compare traditional screen packs with modern gap filters:

| Feature | Screen Pack | Gap Filter |

| Filtration Area | Limited | Extensive |

| Pressure Drop | High | Low |

| Contaminant Capacity | Low | High |

| Cleaning Frequency | Often | Less Frequent |

Conclusion

Choosing the right nozzle is crucial for optimal injection molding performance. It affects material flow, part quality, and production efficiency. Regular maintenance extends nozzle life and ensures consistent output. Clean and inspect nozzles frequently to prevent issues. The future of injection molding nozzles looks promising. We can expect advancements in filtering, mixing, and shut-off mechanisms. These innovations will likely improve efficiency and product quality while reducing downtime and material waste.

FAQs About Injection Molding Nozzles

1. What is an injection molding nozzle?

An injection molding nozzle directs the flow of molten plastic from the machine's barrel into the mold, ensuring efficient and precise part production.

2. How do I choose the right nozzle for my application?

Choose based on material compatibility, machine and mold specifications, and flow characteristics. Matching the nozzle to the plastic type and production needs is essential for efficiency.

3. What is the difference between screen-pack and gap-filter nozzles?

Screen-pack nozzles use metal disks with holes to filter contaminants, while gap-filter nozzles offer larger flow areas, reducing pressure drops and allowing longer use between cleanings.

4. Why does my injection molding nozzle leak?

Leaks often occur due to low contact pressure between the nozzle and sprue bushing or misalignment. Adjusting pressure and checking for proper alignment can resolve this.

5. How can I prevent pressure drops in the nozzle?

Switch to gap-filter nozzles to reduce pressure drop. Regular cleaning of screen-pack filters also helps maintain consistent pressure.

6. How often should injection molding nozzles be cleaned?

Screen-pack nozzles should be cleaned after each run, while gap-filter nozzles can go longer between cleanings, depending on contamination levels.

7. What advancements can we expect in injection molding nozzles?

Future innovations will likely focus on improved filtering, mixing, and shut-off mechanisms, further enhancing production efficiency and product quality.---