Did you know that over 80% of all plastic products around you were made using either injection molding or vacuum forming? These two manufacturing titans shape our everyday items differently.

Making the wrong choice between these processes can cost your business thousands of dollars. Many manufacturers struggle with this decision, impacting their production costs and timelines.

In this comprehensive guide, we'll explore the key differences between injection molding and vacuum forming. You'll learn how each process works, their cost implications, and which method best suits your specific manufacturing needs.

Understanding the Basics: Injection Molding vs. Vacuum Forming Processes

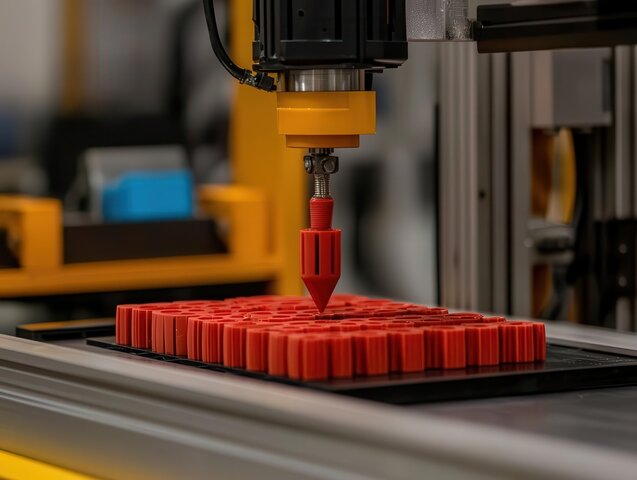

What is Injection Molding?

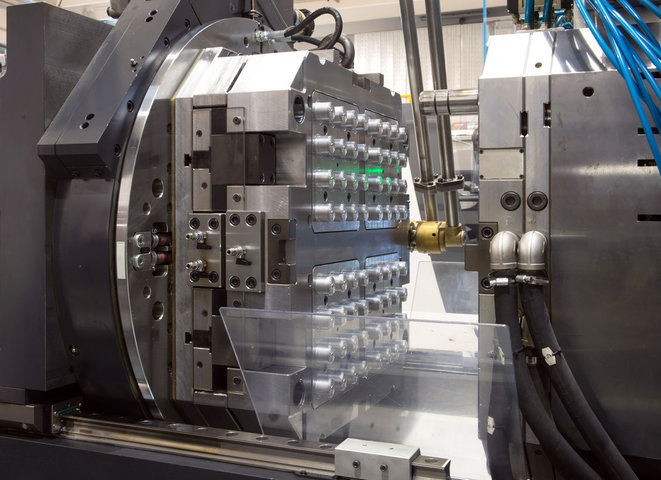

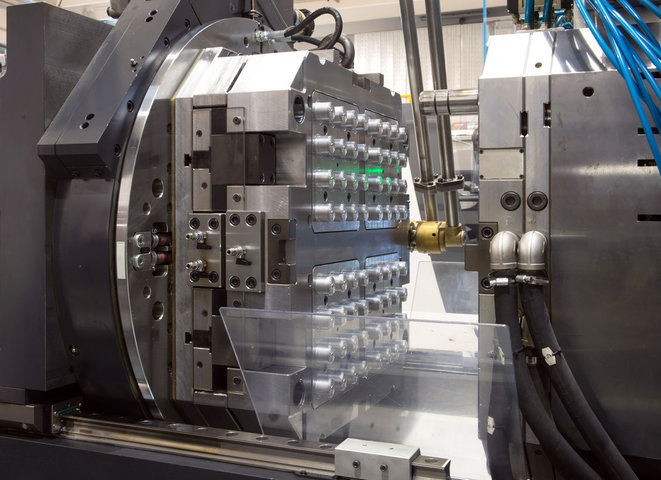

Injection molding is a highly versatile manufacturing process that creates precise, durable plastic parts. It involves melting plastic pellets, injecting them into a mold under high pressure, and cooling them into solid shapes.

Step-by-Step Process:

Loading Pellets: Plastic pellets or granules are poured into a hopper.

Heating and Melting: Pellets are heated in a barrel, turning into molten plastic.

Injection: The molten material is forced into a mold cavity using a high-pressure screw or ram.

Cooling: The plastic cools inside the mold, hardening into the final part shape.

Ejection: Once cooled, the part is ejected from the mold, ready for finishing.

Key Components of Injection Molding Machinery:

Hopper: Holds and feeds plastic pellets into the machine.

Barrel: Where the plastic is heated and melted.

Screw/Reciprocating Screw: Forces molten plastic into the mold.

Mold Cavity: The space where the plastic forms into the desired part.

Clamping Unit: Keeps the mold closed during injection and cooling.

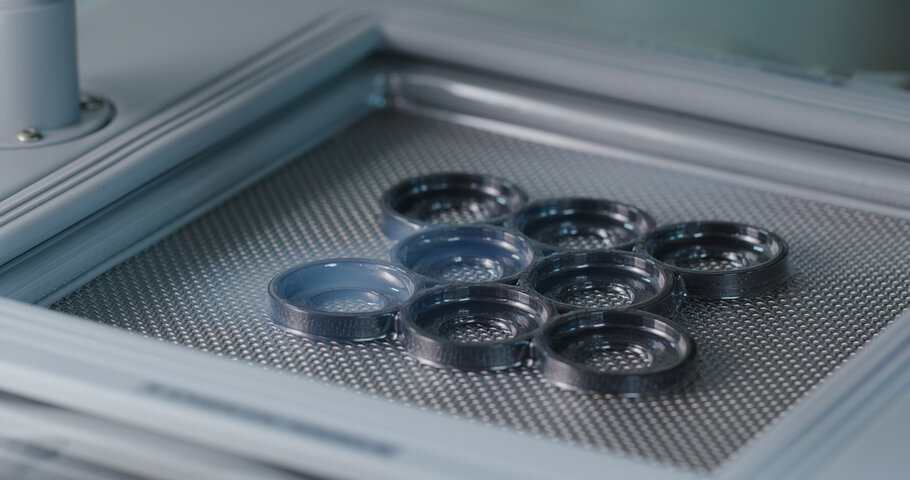

What is Vacuum Forming?

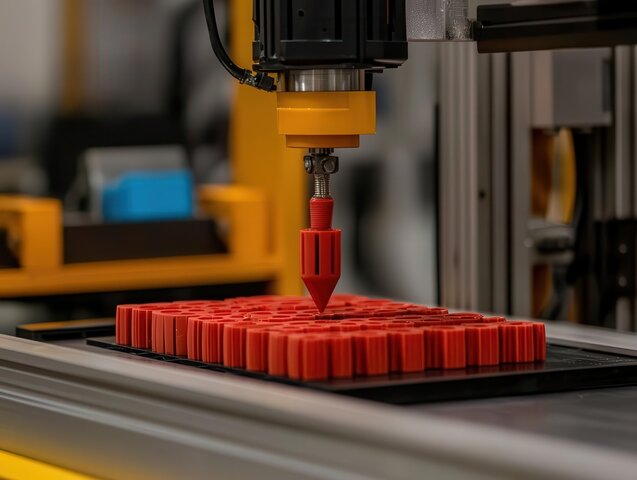

Vacuum forming, a simpler process compared to injection molding, is ideal for creating large, lightweight parts. It involves heating a plastic sheet until soft, then using vacuum pressure to mold it into the desired shape.

Step-by-Step Thermoforming Process:

Clamping: The plastic sheet is clamped in place.

Heating: The sheet is heated until it becomes pliable.

Molding: The softened sheet is stretched over a mold, and a vacuum is applied to shape the part.

Cooling: The molded plastic cools and hardens in place.

Trimming: Excess material is trimmed off, leaving the final product.

Essential Equipment and Components:

Heating Element: Softens the plastic sheet for molding.

Mold (Convex/Concave): Defines the shape of the final part.

Vacuum: Suctions the plastic against the mold to form the shape.

Trimming Tools: Cut away excess plastic after molding.

Comparing Manufacturing Capabilities

Design Complexity and Limitations

Manufacturing capabilities vary significantly between injection molding and vacuum forming. Each process offers unique advantages for specific design requirements.

Injection molding excels in:

Creating intricate details down to microscopic levels

Producing solid, complex geometries including internal structures

Manufacturing parts requiring precise tolerances

Incorporating multiple material types in single components

Vacuum forming strengths include:

Fabricating large-scale components efficiently

Creating uniform wall thickness across expansive surfaces

Developing lightweight, hollow structures

Producing simple geometric shapes cost-effectively

Size and Thickness Considerations

| Feature | Injection Molding | Vacuum Forming |

| Maximum Part Size | Limited by machine capacity | Excellent for large parts |

| Minimum Wall Thickness | 0.5mm | 0.1mm |

| Thickness Consistency | Highly controlled | Varies by stretch |

| Design Flexibility | Complex geometries | Simple to moderate shapes |

Material Selection

The materials used in injection molding and vacuum forming differ in both variety and application, affecting product performance.

Materials Suitable for Injection Molding

Injection molding supports a wide range of thermoplastics and thermosets, including:

Polypropylene (PP), ABS, Nylon, and Polycarbonate (PC) for high-performance applications.

Filled polymers, like glass-filled or fiber-reinforced materials, which enhance strength and durability.

Materials Compatible with Vacuum Forming

Vacuum forming is limited to thermoplastics in sheet form, such as:

Polyethylene (PE), Acrylic, PVC, and HIPS (high-impact polystyrene).

UV-stable and fire-retardant materials for specific applications.

Material Property Comparisons

Injection Molding: Offers a broader selection, including heat-resistant, chemical-resistant, and high-strength polymers.

Vacuum Forming: Works best with lightweight, flexible thermoplastics but offers fewer high-performance material options.

Special Material Considerations

Injection Molding can accommodate materials that require compounding, such as antistatic or biocompatible plastics.

Vacuum Forming is ideal for simpler, bulkier parts where material flexibility and cost are primary concerns.

Cost Analysis: Injection Molding vs. Vacuum Forming

When evaluating the cost-effectiveness of injection molding and vacuum forming, understanding the associated expenses is crucial. Both processes have unique cost structures influenced by tooling, production volume, and labor.

Initial Investment and Tooling Costs

The initial investment varies significantly between these manufacturing methods. Understanding these differences helps businesses make informed financial decisions.

Injection Molding Setup Costs:

Mold tooling: $10,000-$100,000+ depending on complexity

Machine investment: $50,000-$200,000 for standard equipment

Additional peripherals: $15,000-$30,000 for cooling systems, material handling

Vacuum Forming Setup Costs:

Tool creation: $2,000-$15,000 for typical applications

Equipment investment: $20,000-$75,000 for basic systems

Support equipment: $5,000-$10,000 for trimming, heating systems

Equipment Requirements Comparison:

| Component | Injection Molding | Vacuum Forming |

| Primary Machine | High-pressure injection system | Vacuum forming station |

| Tooling Material | Hardened steel, aluminum | Wood, aluminum, epoxy |

| Auxiliary Equipment | Material dryers, chillers | Sheet heating systems |

| Quality Control | Advanced measurement tools | Basic inspection equipment |

Production Costs

Production expenses depend heavily on volume requirements and operational factors.

Cost Per Unit Analysis:

Injection Molding:

High initial costs spread across larger production runs

Lower material waste through precise material control

Reduced labor costs in automated operations

Optimal for quantities exceeding 10,000 units

Vacuum Forming:

Lower startup costs benefit small production runs

Higher material waste from sheet trimming

Increased labor requirements for finishing

Cost-effective under 3,000 units

Break-Even Analysis:

Low Volume (< 1,000 units): Vacuum forming proves more economical

Medium Volume (1,000-10,000): Cost comparison needed based on part specifications

High Volume (> 10,000): Injection molding becomes significantly more cost-effective

Operational Cost Factors:

| Cost Element | Injection Molding | Vacuum Forming |

| Labor Requirements | Low (automated) | Medium to High |

| Material Efficiency | 98% | 70-85% |

| Energy Consumption | High | Medium |

| Maintenance Costs | Moderate to High | Low to Moderate |

Production Considerations

When choosing between injection molding and vacuum forming, manufacturers must evaluate several production-related factors, such as volume, speed, and lead times. Understanding how these processes compare helps in making informed decisions.

Production Volume

Production volume significantly influences manufacturing method selection. Each process offers distinct advantages at different scales.

Low-Volume Production (< 3,000 units)

Vacuum forming provides cost-effective solutions for prototype runs

Tooling modifications remain simple and affordable

Quick setup enables rapid design iterations

Lower initial investment suits limited production needs

High-Volume Manufacturing (> 10,000 units)

Injection molding delivers superior economics at scale

Automated processes reduce labor costs

Consistent quality across large production runs

Multiple cavity tools increase output efficiency

Scalability Comparison:

| Factor | Injection Molding | Vacuum Forming |

| Initial Capacity | Medium to High | Low to Medium |

| Scaling Ease | Complex tool modifications | Simple tool adjustments |

| Output Rate | 100-1000+ parts/hour | 10-50 parts/hour |

| Production Flexibility | Limited | High |

Lead Times and Time-to-Market

Understanding timeline requirements helps optimize project planning and resource allocation.

Development Timeframes:

Injection Molding:

Tool design and manufacturing: 12-16 weeks

Material selection and testing: 2-3 weeks

Production setup and validation: 1-2 weeks

First article inspection: 1 week

Vacuum Forming:

Tool fabrication: 6-8 weeks

Material procurement: 1-2 weeks

Process setup: 2-3 days

Sample validation: 2-3 days

Manufacturing Cycle Comparison:

| Process Phase | Injection Molding | Vacuum Forming |

| Setup Time | 4-8 hours | 1-2 hours |

| Cycle Time | 15-60 seconds | 2-5 minutes |

| Changeover Time | 2-4 hours | 30-60 minutes |

| Quality Checks | Continuous | Batch-based |

Project Timeline Considerations:

Product complexity impacts tool development

Material availability affects lead times

Quality requirements influence validation periods

Production volume determines total project duration

Quality and Performance Factors

Precision and Tolerances

Manufacturing quality differs significantly between these processes. Understanding these variations helps ensure product specifications match process capabilities.

Dimensional Accuracy Comparison:

| Feature | Injection Molding | Vacuum Forming |

| Tolerance Range | ±0.1mm | ±0.5mm |

| Detail Resolution | Excellent | Moderate |

| Consistency | Highly repeatable | Variable |

| Corner Definition | Sharp | Rounded |

Surface Finish Characteristics:

Injection molding achieves Class A surfaces directly from the mold

Vacuum forming maintains consistent texture across large surfaces

Both processes support various textures through mold surface treatments

Post-processing options enhance final appearance

Quality Control Measures:

Injection Molding Controls:

In-line dimensional monitoring

Automated visual inspection

Statistical process control

Material property verification

Vacuum Forming Controls:

Sheet thickness measurements

Manual dimensional checks

Visual surface inspection

Temperature monitoring systems

Strength and Durability

Product performance requirements often determine process selection. Each method offers distinct structural advantages.

Structural Performance:

Injection Molding Benefits:

Uniform material distribution enhances strength

Internal reinforcement possibilities

Precise control over material properties

Complex geometry support for structural elements

Vacuum Forming Characteristics:

Consistent wall thickness in simple geometries

Limited structural design options

Good strength-to-weight ratio

Excellent impact absorption in certain applications

Environmental Resistance Chart:

| Factor | Injection Molding | Vacuum Forming |

| UV Stability | Material dependent | Good |

| Chemical Resistance | Excellent | Moderate |

| Temperature Range | -40°C to 150°C | -20°C to 80°C |

| Moisture Resistance | Superior | Good |

Long-term Performance Factors:

Material degradation rates

Stress cracking resistance

Color stability

Impact strength retention

Applications and Industry Usage

Understanding the applications and industry usage of injection molding and vacuum forming is critical when choosing the right manufacturing process. Each method offers distinct advantages that suit specific industries and product types.

Common Applications

Injection Molding Typical Uses

Injection molding is widely used for producing complex, high-volume parts with precise features. Its applications include:

Electronic housings: Protects internal components with durable, heat-resistant plastic.

Automotive parts: Engine components, clips, and fasteners benefit from high precision.

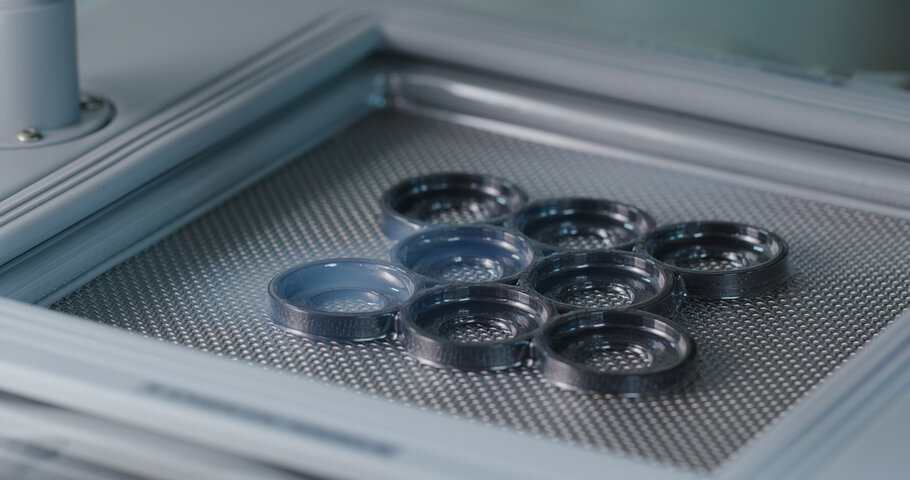

Medical devices: Surgical tools, syringes, and diagnostic equipment require clean, consistent production.

Vacuum Forming Typical Uses

Vacuum forming is preferred for larger, lightweight parts and prototyping. It’s commonly used in:

Packaging trays: Custom-shaped trays for medical, food, or consumer goods.

Automotive interior panels: Larger dashboard and trim components.

Point-of-sale displays: Sturdy but lightweight plastic displays for retail environments.

Industry-Specific Applications

Aerospace: Vacuum forming is used for lightweight interior panels and trays, while injection molding creates intricate components.

Consumer Electronics: Injection molding is critical for protective cases, plugs, and device enclosures.

Food and Beverage Packaging: Vacuum forming produces lightweight, protective plastic packaging that conforms to food safety standards.

| Industry | Injection Molding Examples | Vacuum Forming Examples |

| Automotive | Engine parts, fasteners | Dashboards, trim panels |

| Medical Devices | Syringes, diagnostic tools | Medical trays, packaging |

| Consumer Products | Electronic housings, toys | Large packaging, point-of-sale displays |

Industry-Specific Requirements

Automotive Industry Needs

Injection Molding: The automotive industry demands high precision for parts like fasteners, engine components, and clips. Injection molding meets these needs through consistent production of durable, heat-resistant parts.

Vacuum Forming: Used for larger parts, like door panels, dashboards, and trunk liners, which require lightweight construction.

Medical Device Manufacturing

Injection Molding: Ideal for producing high-precision, sterile components, such as syringes, diagnostic kits, and surgical instruments.

Vacuum Forming: Commonly used for creating custom packaging for medical tools or sterilized trays used in hospitals.

Consumer Products

Injection Molding: Critical for small, detailed consumer goods, such as electronic device housings, plastic toys, and kitchen utensils.

Vacuum Forming: Ideal for large displays, packaging, and protective cases used in retail environments.

Packaging Solutions

Injection Molding: Suitable for creating reusable, rigid containers and protective enclosures.

Vacuum Forming: Widely used for blister packs, clamshell packaging, and lightweight trays that can be mass-produced quickly.

Making the Right Choice

Selecting between injection molding and vacuum forming depends on several key factors. By assessing project-specific needs and understanding the advantages of each method, manufacturers can make an informed decision that aligns with their production goals.

Decision-Making Factors

Project Requirements Assessment

Evaluating your project’s design complexity, part size, and production volume is essential. If your project involves intricate parts with tight tolerances, injection molding may be the better option. For simpler, larger parts, vacuum forming could provide better cost and speed advantages.

Budget Considerations

Injection Molding: Higher upfront tooling costs but reduced cost per part in high-volume production.

Vacuum Forming: Lower tooling costs, ideal for low- to medium-volume production or prototyping.

Timeline Requirements

Quality Specifications

Consider the required dimensional accuracy, surface finish, and material strength. Injection molding delivers superior quality and consistency, while vacuum forming provides good results for less demanding applications.

When to Choose Injection Molding

Ideal Scenarios

High-volume production of small, complex parts.

Projects requiring tight tolerances and detailed features, such as threaded components or snap-fits.

Key Advantages

Cost-effectiveness for large-scale production.

High precision and repeatability for complex designs.

Durability and long-term performance with advanced materials.

Potential Limitations

Cost-Benefit Analysis

While initial expenses are high, injection molding is more economical for high volumes due to lower per-unit costs. The process is also ideal when precision and material strength are critical.

| Injection Molding | Advantages | Limitations |

| Ideal for complex parts | High upfront costs |

|

| Cost-effective for large runs | Longer setup and lead times |

|

| High part-to-part consistency |

|

|

When to Choose Vacuum Forming

Best-Use Cases

Prototyping or low-volume production runs.

Large, simple parts like automotive dashboards, packaging trays, or point-of-sale displays.

Main Benefits

Low tooling costs and faster production setup.

Ideal for quick turnarounds on prototypes or limited runs.

Suitable for large parts that don’t require intricate detailing.

Limitations to Consider

ROI Factors

Vacuum forming offers rapid time-to-market, especially for low-volume runs, but is less suitable for long-term, large-scale production due to higher per-unit costs for larger volumes.

| Vacuum Forming | Benefits | Limitations |

| Quick setup for prototypes | Limited design complexity and precision |

|

| Cost-effective for small runs | Higher per-unit costs for large volumes |

|

| Suitable for large parts |

|

|

Summary

Injection molding and vacuum forming are two key manufacturing methods, each with distinct advantages. Injection molding excels in producing complex, high-volume parts with superior precision and durability. Vacuum forming is ideal for large, simpler parts and low-volume production due to its lower tooling costs and faster setup.

When deciding between the two, consider your project's volume, design complexity, and budget. Use injection molding for high-precision, durable parts. Choose vacuum forming for prototypes or low-cost, fast production.

Ultimately, the right method depends on your specific requirements and long-term goals.

Reference Sources

Vacuum forming

Injection Molding

Top Injection Molding Service

FAQs

Q: What is the main difference between injection molding and vacuum forming?

A: Injection molding injects melted plastic into molds. Vacuum forming stretches heated plastic sheets over molds using suction.

Q: Which process is better for high-volume production?

A: Injection molding excels at high volumes over 10,000 units with faster cycle times and automated production.

Q: Can vacuum forming create parts with intricate details and tight tolerances?

A: No. Vacuum forming creates simpler shapes with looser tolerances than injection molding.

Q: Is injection molding more expensive than vacuum forming?

A: Initial tooling costs are higher for injection molding, but unit costs become lower at high volumes.

Q: What materials can be used in injection molding and vacuum forming?

A: Injection molding uses various plastic pellets. Vacuum forming works only with thermoplastic sheets.