Can you DIY injection molding?

Yes. With a bit of elbow grease, DIY injection molding options are also becoming available.

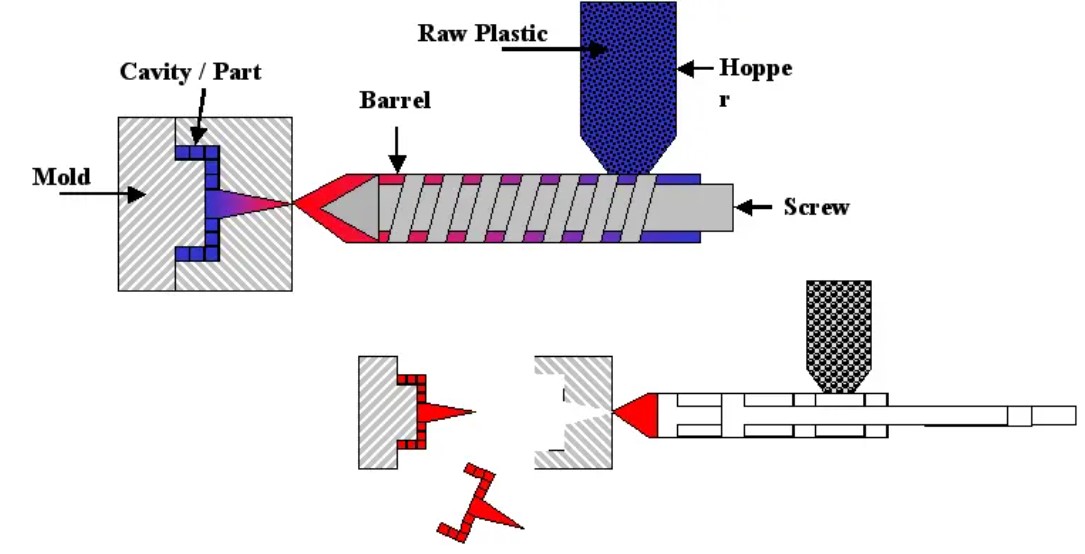

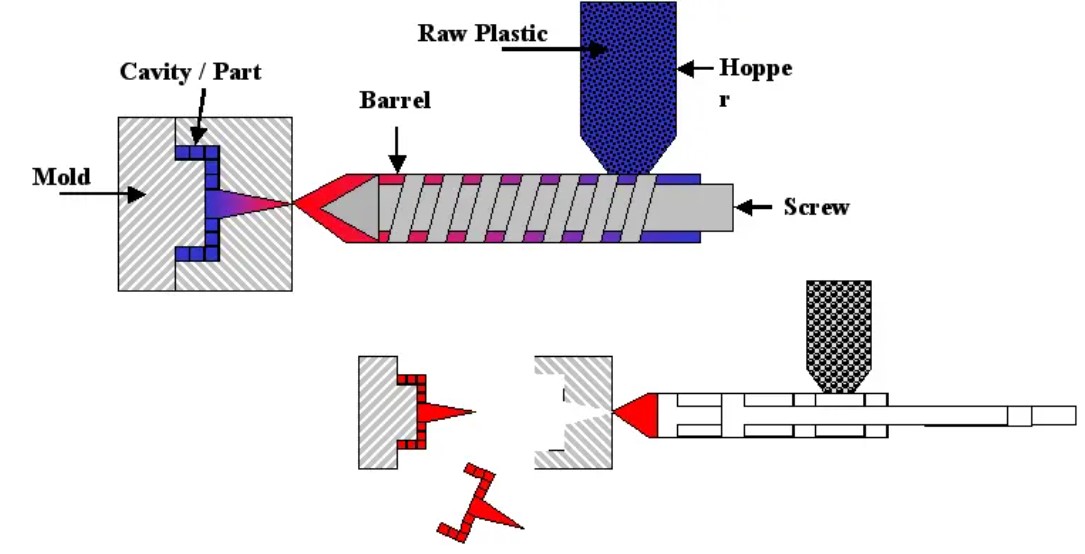

The injection molding process uses large injection molding machines, which advance the resins through six major processes to produce everything from computer parts to plastic Halloween spiders. Although this machine is a complex piece of equipment, it consists of two basic elements: the injection unit and the clamping unit.

TEAM MFG has extensive in-house capabilities for precision quality plastic injection molding across a wide range of product sizes. We utilize a wide range of materials in numerous colors. The plastic materials we commonly work with include PA, PE, PP, PC, ABS, TPR, PVC and other specialty plastics.

TEAM MFG can provide the manufacture service a wide range of injection-molded components varying in complexity from simple split molds to complex multi-plate molds. To simplify this process, we maintain hundreds of standard injection molding dies, and have extensive in-house tooling and die making capabilities to produce plastic injection molding products quickly and cost effectively.

In addition to a full line of standard off-the-shelf injection molded components used in various floor protection applications, we also custom design and manufacture plastic injection molded products in virtually any material or any color, with psi specifications ranging from 30 to 220 tons. TEAM MFG also performs insert molding, with secondary plastic or metal components embedded into the primary injection molding part.

Our experienced engineers are ready to provide you with expert support throughout all stages of product design and development. They will stay continuously involved in the project to ensure that our injection-molded parts will meet and exceed your performance requirements.

In addition to in-house injection molding manufacturing capabilities, we also offer dedicated global sourcing capabilities to import highly economical solutions that are especially beneficial for large production runs. All globally sources products are made to the exact same specifications as our products.