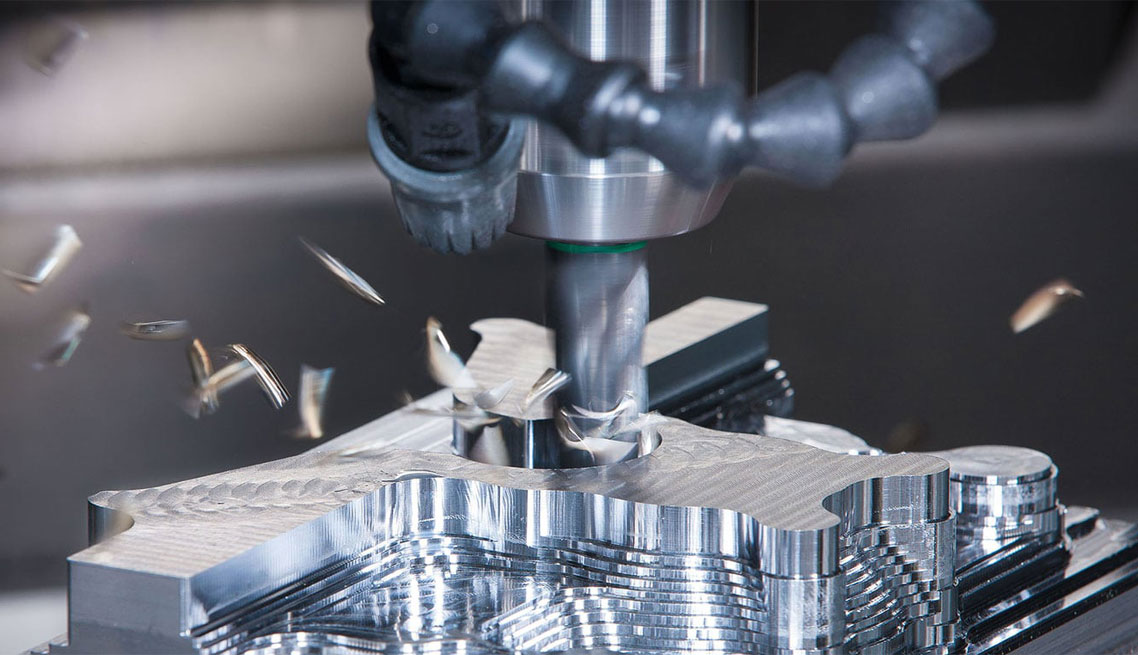

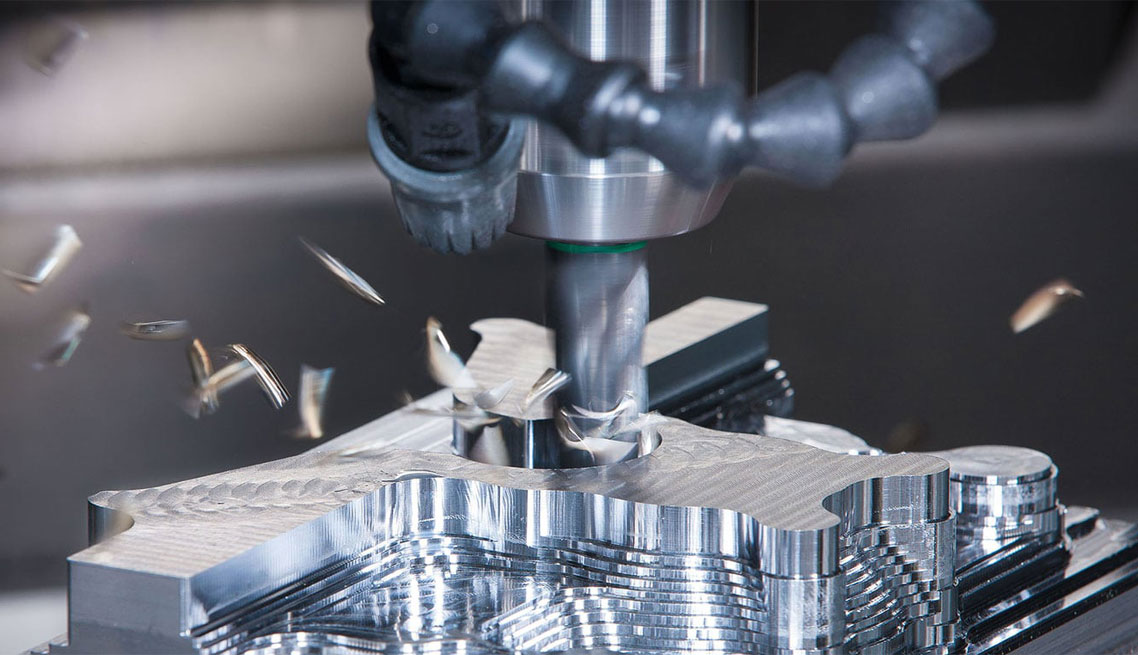

Machining has come a long way since the days of manual lathes and mills. With the advent of Computer Numerical Control (CNC) technology, precision machining has reached new heights. CNC machines, guided by computer programs, have revolutionized the manufacturing industry, enabling the production of complex parts with unparalleled accuracy and consistency.

This comprehensive guide aims to provide a deep dive into the world of CNC precision machining. We'll explore the processes, benefits, and applications of this cutting-edge technology. Whether you're a manufacturing professional, a student, or simply curious about CNC machining, this article will equip you with the knowledge you need to understand and appreciate this fascinating field.

What is CNC Precision Machining?

CNC precision machining is a manufacturing process that uses computer-controlled machine tools to create highly accurate and complex parts from raw materials. The process involves the use of specialized software to generate detailed instructions, known as G-code, which guide the machine tools to cut, drill, or shape the material to the desired specifications.

Key components of a CNC precision machining system include:

1. Computer Aided Design (CAD) software

2. Computer Aided Manufacturing (CAM) software

3. CNC machine tools (e.g., mills, lathes, routers)

4. Cutting tools and accessories

5. Workholding devices

The main difference between CNC precision machining and traditional precision machining lies in the level of automation and the role of computer control. Traditional precision machining relies heavily on the skill and experience of the machine operator, who manually controls the machine tools. In contrast, CNC precision machining minimizes human intervention by using computer programs to control the machine tools, resulting in higher accuracy, consistency, and repeatability.

Traditional Precision Machining | CNC Precision Machining |

Manual control | Computer control |

Operator skill-dependent | Automated process |

Longer setup times | Faster setup times |

Limited complexity | High complexity |

Lower repeatability | Higher repeatability |

Computer Numerical Control (CNC) is the foundation of precision machining. CNC systems use computer programs to control the motion and operation of machine tools. The programs contain a series of instructions that define the tool paths, cutting speeds, and feed rates required to produce the desired part geometry. By automating the machining process, CNC technology enables manufacturers to achieve tight tolerances, intricate designs, and superior surface finishes with minimal human error.

Advantages of CNC Precision Machining

CNC precision machining offers numerous benefits that make it an indispensable tool in modern manufacturing. Here are some of the key advantages:

1. High Accuracy and Precision

One of the most significant advantages of CNC precision machining is its ability to produce parts with extremely tight tolerances. CNC machines can achieve accuracies up to ±0.0002 inches, ensuring that the manufactured components meet the exact specifications required for optimal performance.

2. Consistency and Repeatability

CNC precision machining guarantees consistent results across multiple production runs. Once a program is created and tested, the CNC machine can reproduce identical parts time and time again, minimizing variations and ensuring a high level of repeatability.

3. Increased Production Speed and Efficiency

Compared to traditional machining methods, CNC precision machining significantly reduces production time. The automated process allows for faster cutting speeds, reduced setup times, and minimal operator intervention, resulting in increased overall efficiency and productivity.

4. Cost-Effectiveness for Large-Scale Manufacturing

While the initial investment in CNC precision machining equipment may be higher than traditional machining tools, the long-term cost benefits are substantial, particularly for large-scale manufacturing. The increased efficiency, reduced labor costs, and minimized material waste contribute to lower production costs per unit.

5. Ability to Handle Complex Designs and Geometries

CNC precision machining excels at producing parts with complex geometries and intricate details. The computer-controlled process allows for the creation of sophisticated shapes, contours, and cavities that would be challenging or impossible to achieve with manual machining methods.

6. Reduced Human Error and Improved Quality Control

By minimizing human intervention in the machining process, CNC precision machining significantly reduces the risk of errors and inconsistencies. The computer-controlled system ensures that each part is produced according to the exact specifications, leading to improved quality control and reduced reject rates.

Benefits of CNC Precision Machining:

l High accuracy and precision

l Consistent and repeatable results

l Faster production times

l Cost-effective for large-scale manufacturing

l Ability to create complex geometries

l Reduced human error and improved quality control

Types of CNC Precision Machining Equipment

CNC Milling Machines

CNC milling machines are versatile tools that use rotary cutters to remove material from a workpiece, creating a wide range of shapes and features. These machines are capable of performing various operations, such as face milling, peripheral milling, drilling, and boring.

Key features of CNC milling machines include:

l Multiple axes of motion (typically 3, 4, or 5 axes)

l Adjustable spindle speeds and feed rates

l Automatic tool changers for increased efficiency

l Compatibility with a wide range of materials, including metals, plastics, and composites

CNC milling machines are classified based on their orientation and configuration:

1. Vertical Milling Machines

a. Spindle is oriented vertically

b. Ideal for creating flat surfaces, slots, and pockets

c. Common types include bed mills, turret mills, and knee mills

2. Horizontal Milling Machines

a. Spindle is oriented horizontally

b. Well-suited for machining large, heavy workpieces

c. Offers increased rigidity and chip removal compared to vertical mills

3. Universal Milling Machines

a. Combine features of both vertical and horizontal mills

b. Swiveling head allows for more complex angles and contours

c. Provides greater flexibility for diverse machining applications

Milling Machine Type | Spindle Orientation | Workpiece Orientation | Common Applications |

Vertical | Vertical | Horizontal | Flat surfaces, slots, pockets |

Horizontal | Horizontal | Vertical | Large, heavy parts; improved chip removal |

Universal | Swiveling | Varies | Complex angles and contours; diverse applications |

CNC milling machines are essential for producing a wide array of precision components across various industries, including automotive, aerospace, medical, and manufacturing. The ability to create complex geometries, tight tolerances, and smooth surface finishes makes CNC milling machines indispensable in modern precision machining.

CNC Lathes and Turning Centers

CNC lathes and turning centers are precision machining equipment designed to produce cylindrical parts by rotating the workpiece against a stationary cutting tool. These machines are essential for manufacturing components with circular cross-sections, such as shafts, bushings, and bearings.

Key features of CNC lathes and turning centers include:

l Powerful spindle motors for high-speed rotation

l Precise servo motors for accurate tool positioning

l Automatic tool changers for increased efficiency

l Live tooling capabilities for milling and drilling operations

Types of CNC lathes and turning centers:

1. 2-Axis Lathes

a. Move the cutting tool in two axes (X and Z)

b. Ideal for simple turning operations and facing

2. Multi-Axis Lathes

a. Feature additional axes (Y, B, or C) for more complex geometries

b. Enable off-center turning, contouring, and eccentric machining

3. Swiss-Type Lathes

a. Designed for precision machining of small, slender parts

b. Utilize a sliding headstock and guide bushing for enhanced accuracy

c. Well-suited for manufacturing medical and electronic components

Lathe Type | Axes of Motion | Key Features | Common Applications |

2-Axis | X, Z | Simple turning and facing | Shafts, spacers, bushings |

Multi-Axis | X, Z, Y, B, C | Complex geometries, contouring | Cams, gears, eccentric parts |

Swiss-Type | X, Z, Y, B, C | Precision machining of small parts | Medical, electronic components |

CNC lathes and turning centers offer several advantages over traditional manual lathes:

l Increased accuracy and repeatability

l Higher production speeds and reduced lead times

l Ability to machine complex geometries and tight tolerances

l Reduced labor costs and improved efficiency

These machines are crucial for producing high-precision turned parts in various industries, including automotive, aerospace, medical, and oil and gas. With the advancements in CNC technology, modern turning centers continue to push the boundaries of precision, speed, and complexity in machining cylindrical components.

CNC Grinders

CNC grinders are precision machining tools used for finishing operations, ensuring that parts meet the required surface finish and tolerance specifications. These machines use abrasive wheels to remove small amounts of material from the workpiece, resulting in extremely smooth surfaces and tight tolerances.

Types of CNC grinders:

1. Surface Grinders

a. Use a rotating abrasive wheel to create flat, smooth surfaces

b. Ideal for finishing plate-like components and creating precise angles

2. Cylindrical Grinders

a. Designed for grinding the outside diameter (OD) of cylindrical parts

b. Can also be used for internal diameter (ID) grinding with specialized attachments

3. Centerless Grinders

a. Utilize a grinding wheel, regulating wheel, and work blade to grind cylindrical parts

b. Eliminate the need for workpiece centers, allowing for faster production rates

Grinder Type | Workpiece Geometry | Grinding Action | Common Applications |

Surface | Flat, plate-like | Rotating wheel | Mold plates, die components, gauges |

Cylindrical | Cylindrical | Rotating wheel | Shafts, pins, bearings, spindles |

Centerless | Cylindrical | Rotating wheels | Valves, pistons, rods, pins |

Key benefits of CNC grinders:

l Achieve extremely tight tolerances (up to ±0.0001 inches)

l Produce superior surface finishes (as low as Ra 0.2 μm)

l Maintain high accuracy and repeatability across multiple parts

l Reduce labor costs and increase efficiency compared to manual grinding

CNC grinders are essential for producing high-precision components in various industries, including:

l Aerospace: Turbine blades, landing gear components, and engine parts

l Automotive: Transmission components, engine valves, and fuel injectors

l Medical: Orthopedic implants, surgical instruments, and dental components

l Electronics: Semiconductor components, optical lenses, and precision molds

As technology advances, CNC grinders continue to evolve, offering higher precision, faster production rates, and more versatile grinding capabilities. These machines play a crucial role in ensuring that precision-machined parts meet the stringent requirements of modern manufacturing.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses electrical sparks to remove material from electrically conductive workpieces. This process is ideal for machining hard, exotic materials or creating intricate geometries that are difficult to achieve with traditional cutting tools.

Two main types of EDM:

1. Wire EDM

a. Uses a thin, electrically charged wire to cut through the workpiece

b. Ideal for creating complex, detailed shapes and contours

c. Common applications include dies, punches, and aerospace components

2. Sinker EDM

a. Uses a shaped electrode to erode material from the workpiece

b. Creates cavities, molds, and intricate 3D shapes

c. Well-suited for manufacturing mold inserts, die components, and surgical instruments

EDM Type | Electrode | Machining Action | Common Applications |

Wire EDM | Thin wire | Cuts through workpiece | Dies, punches, aerospace parts |

Sinker EDM | Shaped electrode | Erodes material | Mold inserts, die components, surgical tools |

How EDM works:

1. The workpiece is submerged in a dielectric fluid, usually deionized water or oil

2. A high-voltage current is applied between the electrode (wire or shaped) and the workpiece

3. Electrical sparks jump across the gap, generating intense heat (up to 12,000°C)

4. The heat vaporizes small amounts of material from both the workpiece and the electrode

5. The dielectric fluid flushes away the vaporized material, leaving a precise, machined surface

Advantages of EDM:

l Machines hard, exotic materials like titanium, tungsten carbide, and hardened steel

l Creates complex geometries and intricate details with high accuracy

l Produces no mechanical stress or tool pressure on the workpiece

l Achieves excellent surface finishes without the need for secondary operations

EDM has become an essential precision machining process in various industries, including aerospace, automotive, medical, and electronics. As materials continue to advance and design complexity increases, EDM will remain a vital tool for creating high-precision components that meet the demands of modern manufacturing.

CNC Routers

CNC routers are versatile precision machining tools that are similar to CNC milling machines but are primarily used for machining softer materials, such as wood, plastics, and composites. These machines use high-speed spindles and a variety of cutting tools to create intricate designs, engravings, and 3D shapes.

Key features of CNC routers:

l Multi-axis motion (typically 3 or 5 axes)

l High-speed spindles (up to 30,000 RPM or more)

l Large working areas for machining sizable workpieces

l Compatibility with various tooling options, including end mills, drill bits, and engraving tools

Common applications of CNC routers:

1. Woodworking

a. Furniture production

b. Cabinet making

c. Decorative carvings and engravings

2. Signmaking

a. Creating custom signs and displays

b. Engraving logos and lettering

c. Cutting acrylic, foam board, and other sign materials

3. Aerospace

a. Machining lightweight composite materials

b. Producing interior components, such as panels and bulkheads

c. Creating prototypes and test parts

Industry | Materials | Typical Applications |

Woodworking | Wood, MDF, plywood | Furniture, cabinetry, decorative carvings |

Signmaking | Acrylic, foam board, PVC | Custom signs, logos, displays |

Aerospace | Composites, plastics, aluminum | Interior components, prototypes, test parts |

Benefits of CNC routers:

l Ability to machine large, flat workpieces with high accuracy

l Versatility in machining a wide range of materials

l High-speed production capabilities for increased efficiency

l Ease of use and reduced operator skill requirements compared to traditional routers

As technology advances, CNC routers continue to evolve, offering higher speeds, greater precision, and more advanced features like automatic tool changers and vacuum workholding systems. These machines have become essential tools for businesses looking to streamline their production processes and create high-quality, custom-machined parts in various industries.

CNC Plasma Cutters

CNC plasma cutters are precision machining tools that use a high-velocity jet of ionized gas to cut through electrically conductive materials, such as steel, aluminum, and copper. The plasma arc, which can reach temperatures up to 50,000°F (27,760°C), melts the material while the high-speed gas flow blows the molten material away, creating a clean, precise cut.

Key components of CNC plasma cutters:

1. Plasma torch: Generates the high-temperature plasma arc

2. CNC control system: Directs the movement of the torch along the cutting path

3. Gantry or beam: Supports and moves the torch across the cutting table

4. Cutting table: Supports the workpiece during the cutting process

Advantages of CNC plasma cutting:

l High cutting speeds (up to 500 inches per minute)

l Ability to cut thick materials (up to 2 inches or more)

l Relatively low operating costs compared to other cutting methods

l Versatility in cutting various conductive materials

Common applications of CNC plasma cutters:

Industry | Typical Applications |

Automotive | Chassis components, exhaust systems, body panels |

Construction | Structural steel, girders, beams, pipes |

Manufacturing | Machine parts, brackets, fixtures, custom components |

Art & Decor | Metal sculptures, signs, decorative elements |

Factors affecting CNC plasma cutting quality:

1. Material thickness and composition

2. Cutting speed and torch-to-workpiece distance

3. Gas pressure and flow rate

4. Nozzle size and wear

5. Plasma arc current and voltage

To achieve the best results, operators must carefully adjust these parameters based on the material being cut and the desired cut quality. Regular maintenance, including nozzle replacement and calibration, is also essential for ensuring consistent, high-quality cuts.

As CNC plasma cutting technology continues to advance, these machines are becoming increasingly capable of producing precise, high-quality cuts in a wide range of materials and thicknesses. This versatility makes CNC plasma cutters an essential tool for many fabrication and metal processing applications.

CNC Laser Cutters

CNC laser cutters are precision machining tools that use a highly focused beam of light to cut, engrave, or mark various materials, including metals, plastics, wood, and glass. The laser beam is generated by a laser source, typically a CO2 or fiber laser, and is directed by a series of mirrors and lenses controlled by a CNC system.

Advantages of CNC laser cutting:

1. High precision and accuracy

2. Narrow kerf width (cut width) for minimal material waste

3. No physical contact between the tool and the workpiece

4. Ability to cut intricate shapes and fine details

5. Minimal heat-affected zone (HAZ) for reduced material distortion

Laser Type | Wavelength | Typical Materials | Common Applications |

CO2 | 10.6 μm | Wood, acrylic, plastics, fabric, leather | Signage, packaging, clothing, models |

Fiber | 1.06 μm | Metals (steel, aluminum, brass), ceramics | Electronics, automotive, aerospace |

Key factors affecting CNC laser cutting performance:

l Laser power and wavelength

l Cutting speed and assist gas pressure

l Material properties (thickness, reflectivity, thermal conductivity)

l Focus lens and nozzle condition

To optimize cutting results, operators must carefully select the appropriate laser type, power, and settings based on the material being processed and the desired cut quality. Regular maintenance, including lens cleaning and calibration, is crucial for ensuring consistent performance and prolonging the life of the laser cutting system.

CNC laser cutters offer several unique benefits compared to other cutting methods:

1. Non-contact process eliminates tool wear and breakage

2. Minimal material waste and clean, burr-free edges

3. High speed and efficiency for increased productivity

4. Versatility in processing a wide range of materials and thicknesses

As laser technology continues to evolve, CNC laser cutters are becoming increasingly powerful, precise, and affordable, making them an essential tool for many manufacturing and fabrication applications across various industries, including automotive, aerospace, electronics, and consumer goods.

CNC Precision Machining Materials

Metals

CNC precision machining is compatible with a wide range of metals, each with unique properties and characteristics that make them suitable for different applications. Understanding the properties of these metals is crucial for selecting the appropriate material for your project and ensuring optimal machining performance.

Aluminum

l Lightweight and easy to machine

l Excellent thermal and electrical conductivity

l Good corrosion resistance

l Commonly used in aerospace, automotive, and consumer products

Steel

l High strength and durability

l Wide range of grades and alloys available

l Suitable for applications requiring high wear resistance

l Used in machinery, tools, and structural components

Stainless Steel

l Exceptional corrosion resistance

l Good strength and toughness

l Hygienic and easy to clean

l Ideal for food processing, medical devices, and chemical equipment

Brass

l Excellent machinability

l Good thermal and electrical conductivity

l Attractive appearance and resistance to tarnishing

l Used in decorative hardware, plumbing fixtures, and musical instruments

Copper

l High thermal and electrical conductivity

l Good formability and machinability

l Antimicrobial properties

l Commonly used in electrical components, heat exchangers, and piping systems

Titanium

l Exceptional strength-to-weight ratio

l High corrosion resistance

l Biocompatible and hypoallergenic

l Used in aerospace, medical implants, and high-performance applications

Metal | Key Properties | Common Applications |

Aluminum | Lightweight, conductive, corrosion-resistant | Aerospace, automotive, consumer products |

Steel | Strong, durable, diverse grades | Machinery, tools, structural components |

Stainless Steel | Corrosion-resistant, hygienic | Food processing, medical devices, chemical equipment |

Brass | Machinable, conductive, attractive | Decorative hardware, plumbing, musical instruments |

Copper | Conductive, formable, antimicrobial | Electrical components, heat exchangers, piping |

Titanium | High strength-to-weight, corrosion-resistant | Aerospace, medical implants, high-performance parts |

When selecting a metal for your CNC precision machining project, consider factors such as:

l Mechanical properties (strength, hardness, toughness)

l Thermal and electrical properties

l Corrosion resistance

l Machinability and tool wear

l Cost and availability

By choosing the right metal for your application and optimizing your machining parameters, you can achieve high-quality, precise, and cost-effective results with CNC precision machining.

Plastics

In addition to metals, CNC precision machining is also highly effective for processing various plastic materials. Plastics offer unique advantages, such as lightweight construction, excellent electrical insulation, and good chemical resistance. Here are some common plastic materials used in CNC precision machining:

ABS (Acrylonitrile Butadiene Styrene)

l Good impact resistance and toughness

l Excellent machinability and dimensional stability

l Resistant to chemicals and heat

l Used in automotive parts, household appliances, and toys

PC (Polycarbonate)

l High impact strength and toughness

l Good thermal and electrical insulation properties

l Transparent and available in various colors

l Commonly used in automotive components, medical devices, and safety equipment

PEEK (Polyether Ether Ketone)

l Exceptional strength and stiffness

l Excellent chemical and temperature resistance

l Low moisture absorption and good dimensional stability

l Ideal for aerospace, automotive, and high-performance applications

Nylon (Polyamide)

l High strength and flexibility

l Good wear and abrasion resistance

l Low friction and self-lubricating properties

l Used in gears, bearings, and mechanical components

Acrylic (PMMA)

l Excellent optical clarity and transparency

l Good UV resistance and weatherability

l Easy to machine and polish

l Commonly used in lenses, displays, and signage

Plastic | Key Properties | Common Applications |

ABS | Impact-resistant, machinable, heat-resistant | Automotive parts, household appliances, toys |

PC | High impact strength, transparent, insulating | Automotive components, medical devices, safety equipment |

PEEK | Strong, stiff, chemically resistant | Aerospace, automotive, high-performance parts |

Nylon | Strong, flexible, wear-resistant | Gears, bearings, mechanical components |

Acrylic | Optically clear, UV-resistant, easy to machine | Lenses, displays, signage |

When machining plastics with CNC precision equipment, consider the following:

l Use sharp, high-quality tools specifically designed for plastics

l Adjust cutting speeds and feed rates to prevent melting or deformation

l Provide adequate cooling and chip evacuation to maintain part quality

l Account for thermal expansion and contraction during machining

Composites and Exotic Materials

In addition to traditional metals and plastics, CNC precision machining can also process advanced composite materials and exotic alloys. These materials offer unique properties that make them ideal for demanding applications in industries such as aerospace, defense, and high-performance automotive.

Composites

Composite materials are formed by combining two or more distinct materials to achieve enhanced properties. Common composites used in CNC precision machining include:

l Carbon Fiber Reinforced Polymers (CFRP)

¡ High strength-to-weight ratio

¡ Excellent stiffness and dimensional stability

¡ Used in aerospace structures, sports equipment, and luxury vehicles

l Glass Fiber Reinforced Polymers (GFRP)

¡ Good strength and stiffness at a lower cost than CFRP

¡ Excellent electrical insulation properties

¡ Commonly used in wind turbine blades, boat hulls, and automotive components

l Kevlar (Aramid) Fiber Composites

¡ High tensile strength and impact resistance

¡ Lightweight and flexible

¡ Used in bulletproof vests, aerospace components, and high-performance ropes

Exotic Materials

Exotic materials are advanced alloys and metals with unique properties that make them suitable for extreme environments and demanding applications. Some examples include:

l Inconel

¡ Excellent high-temperature strength and oxidation resistance

¡ Good corrosion resistance and toughness

¡ Used in gas turbine engines, chemical processing equipment, and nuclear reactors

l Monel

¡ High strength and excellent corrosion resistance

¡ Non-magnetic and spark-resistant

¡ Commonly used in marine equipment, chemical processing, and oil and gas industries

l Hastelloy

¡ Outstanding corrosion resistance in harsh environments

¡ Good high-temperature strength and oxidation resistance

¡ Used in chemical processing, nuclear reactors, and aerospace components

Material | Key Properties | Common Applications |

Carbon Fiber Reinforced Polymer | High strength-to-weight, stiff, dimensionally stable | Aerospace structures, sports equipment, luxury vehicles |

Glass Fiber Reinforced Polymer | Good strength and stiffness, electrically insulating | Wind turbine blades, boat hulls, automotive components |

Kevlar (Aramid) Fiber | High tensile strength, impact-resistant, lightweight | Bulletproof vests, aerospace components, high-performance ropes |

Inconel | High-temperature strength, corrosion-resistant | Gas turbine engines, chemical processing, nuclear reactors |

Monel | High strength, corrosion-resistant, non-magnetic | Marine equipment, chemical processing, oil and gas industries |

Hastelloy | Outstanding corrosion resistance, high-temp strength | Chemical processing, nuclear reactors, aerospace components |

When machining composites and exotic materials, consider the following:

l Use diamond-coated or carbide tools for improved wear resistance

l Adjust cutting parameters to minimize delamination and fiber pullout

l Implement proper dust collection and ventilation systems

l Account for material-specific properties, such as anisotropy and thermal sensitivity

Material Selection Considerations for CNC Precision Machining

Choosing the right material for your CNC precision machining project is crucial to ensure optimal performance, functionality, and cost-effectiveness. When selecting a material, consider the following factors:

1. Mechanical Properties

a. Strength: The ability to withstand stress without failing

b. Hardness: Resistance to indentation and wear

c. Toughness: The ability to absorb energy without fracturing

d. Elasticity: The ability to return to its original shape after deformation

2. Thermal Properties

a. Melting point: The temperature at which the material transitions from solid to liquid

b. Thermal conductivity: The ability to transfer heat

c. Thermal expansion: The change in volume due to temperature changes

3. Electrical Properties

a. Conductivity: The ability to conduct electrical current

b. Insulation: The ability to resist the flow of electrical current

c. Dielectric strength: The maximum electric field a material can withstand without breakdown

4. Chemical Properties

a. Corrosion resistance: The ability to withstand degradation in corrosive environments

b. Chemical compatibility: The ability to maintain integrity when exposed to specific chemicals

5. Machinability

a. Ease of cutting, drilling, and shaping the material

b. Tool wear and breakage

c. Chip formation and evacuation

d. Surface finish quality

6. Cost and Availability

a. Raw material cost

b. Processing and machining costs

c. Lead times and minimum order quantities

d. Supplier reliability and consistency

Factor | Considerations |

Mechanical Properties | Strength, hardness, toughness, elasticity |

Thermal Properties | Melting point, thermal conductivity, thermal expansion |

Electrical Properties | Conductivity, insulation, dielectric strength |

Chemical Properties | Corrosion resistance, chemical compatibility |

Machinability | Ease of machining, tool wear, chip formation, surface finish |

Cost and Availability | Raw material cost, processing costs, lead times, supplier reliability |

To make an informed decision, follow these steps:

1. Define the application requirements and operating conditions

2. Identify the critical material properties for your specific application

3. Research and compare potential materials that meet your requirements

4. Consult with material suppliers and CNC machining experts

5. Consider cost and availability factors

6. Select the material that offers the best balance of performance, machinability, and cost

By carefully evaluating your application needs and material options, you can select the optimal material for your CNC precision machining project, ensuring successful results and long-term performance.

CNC Precision Machining Tolerances and Accuracy

Tolerances and accuracy are critical aspects of CNC precision machining, as they directly impact the quality, functionality, and interchangeability of machined parts. Understanding and controlling these factors is essential for producing high-quality components that meet the required specifications.

Understanding Machining Tolerances

Machining tolerances define the acceptable range of deviation from the specified dimensions. There are several types of tolerances:

1. Dimensional tolerances: The allowable variation in size, such as length, width, or diameter

2. Geometric tolerances: The permissible deviation in form, orientation, location, or runout

3. Surface finish tolerances: The acceptable range of surface roughness or texture

Tolerances are typically expressed using symbols and values on engineering drawings, such as:

l ± 0.005" (plus/minus 0.005 inches)

l 0.001" (diameter tolerance of 0.001 inches)

l 32 μin (surface finish of 32 microinches

For more information about machining tolerances, please visit: CNC Machining Tolerances.

Factors Affecting CNC Precision Machining Accuracy

Several factors can influence the accuracy of CNC precision machined parts:

1. Machine tool accuracy: The inherent accuracy of the CNC machine, including its positioning and repeatability

2. Tooling and fixturing: The quality and condition of cutting tools, holders, and workholding devices

3. Environmental conditions: Temperature, humidity, and vibration levels in the machining environment

4. Operator skill: The experience and expertise of the CNC machine operator

5. Material properties: The machinability, stability, and consistency of the workpiece material

Achieving Tight Tolerances in CNC Precision Machining

To achieve tight tolerances and maintain high accuracy, consider the following best practices:

1. Use high-precision CNC machines with linear encoders and rigid construction

2. Regularly calibrate and maintain machine tools, spindles, and axes

3. Employ high-quality, sharp, and wear-resistant cutting tools

4. Implement robust workholding and fixturing solutions to minimize deflection and vibration

5. Control environmental factors, such as temperature and humidity, in the machining area

6. Train and certify CNC machine operators to ensure consistent quality

7. Optimize cutting parameters, such as feed rate, spindle speed, and depth of cut

8. Perform regular in-process and post-process inspections to verify accuracy

Inspection and Quality Control Methods

Inspecting and verifying the accuracy of CNC precision machined parts is crucial for ensuring quality and meeting customer requirements. Common inspection methods include:

1. Coordinate Measuring Machines (CMMs): Automated systems that precisely measure part dimensions and geometries

2. Optical comparators: Devices that use magnified silhouettes to compare part features against a reference drawing

3. Gauge blocks and pins: Physical standards used to verify dimensions and calibrate measuring equipment

4. Surface roughness testers: Instruments that measure and quantify surface texture and finish

5. Statistical Process Control (SPC): A data-driven approach to monitoring and controlling the machining process

Method | Purpose |

Coordinate Measuring Machines | Precise measurement of part dimensions and geometries |

Optical Comparators | Comparison of part features against a reference drawing |

Gauge Blocks and Pins | Verification of dimensions and calibration of measuring equipment |

Surface Roughness Testers | Measurement and quantification of surface texture and finish |

Statistical Process Control | Data-driven monitoring and control of the machining process |

Programming and Software for CNC Precision Machining

Effective programming and software solutions are essential for successful CNC precision machining. These tools enable designers, engineers, and machine operators to create, simulate, and execute complex machining processes with high accuracy and efficiency.

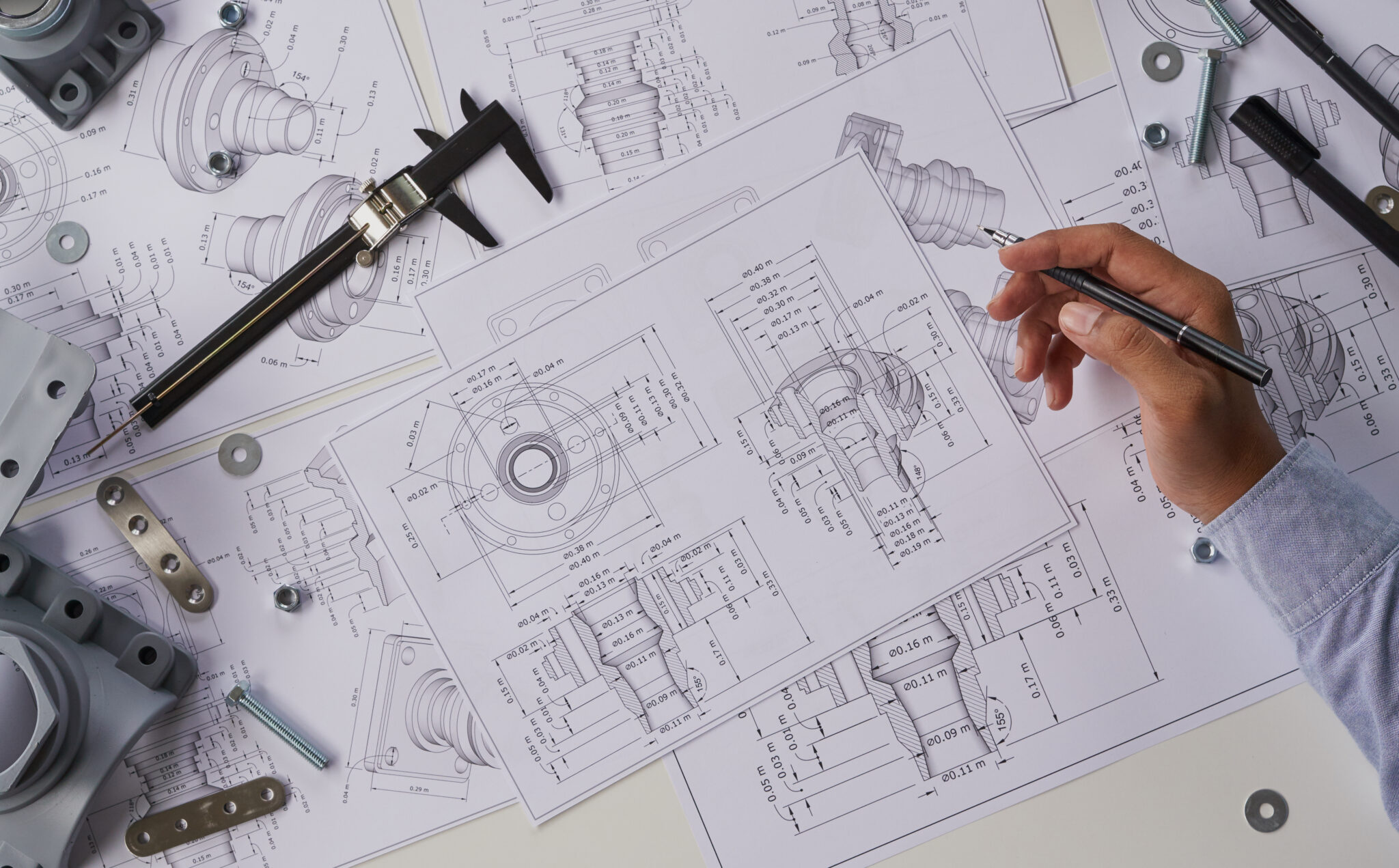

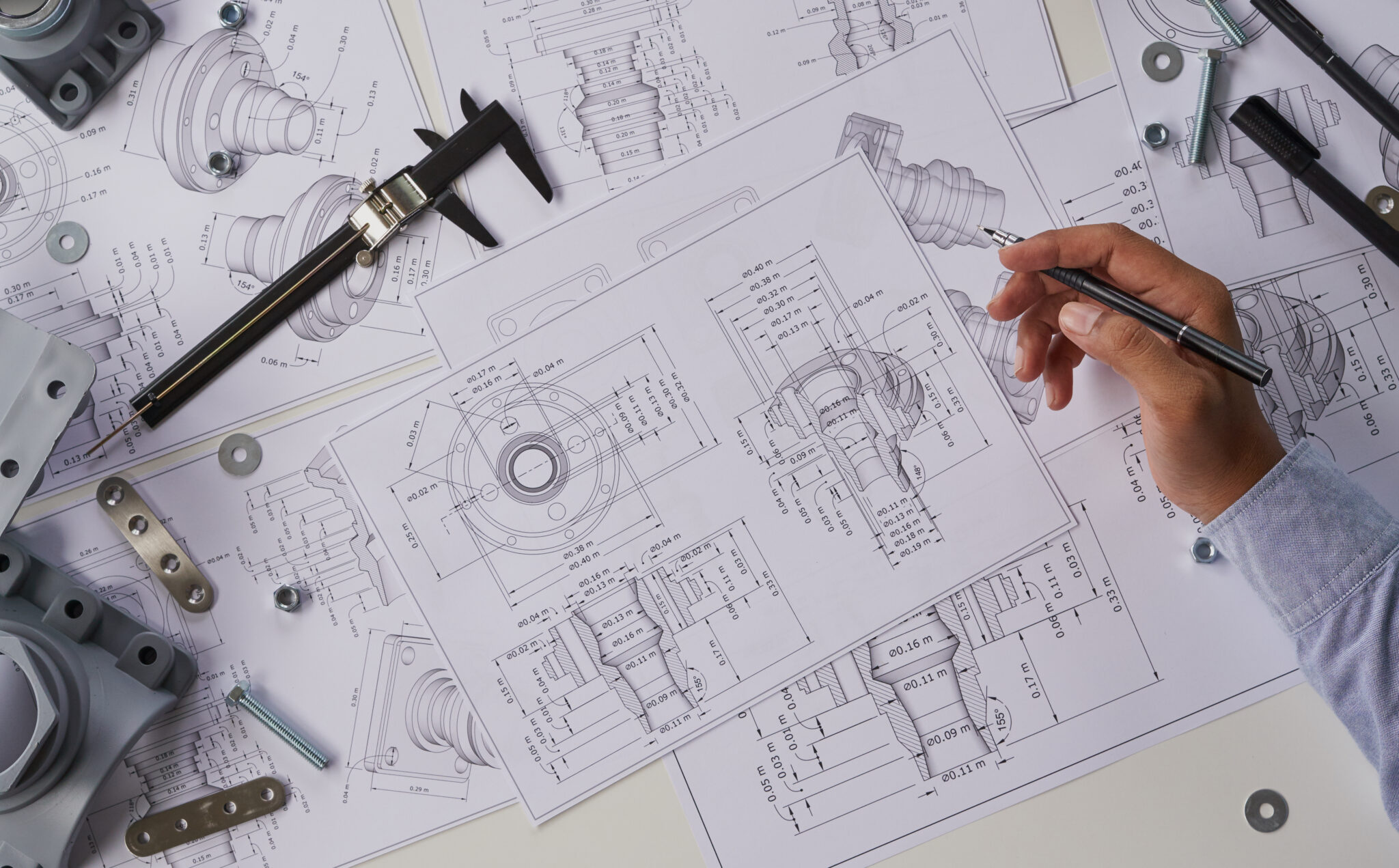

CAD and CAM Software

CAD and CAM software play crucial roles in CNC precision machining:

l CAD software is used to create detailed 2D and 3D models of parts and assemblies

l CAM software takes CAD models and generates tool paths and CNC machine code (G-code and M-code)

Popular CAD and CAM software packages include:

1. AutoCAD and Autodesk Fusion 360

2. SolidWorks and SolidCAM

3. Mastercam

4. CATIA

5. Siemens NX

These software solutions offer powerful features, such as:

l Parametric modeling and design automation

l Tool path optimization and collision avoidance

l Material removal simulation and cycle time estimation

l Post-processing for various CNC machine controllers

G-code and M-code Programming for CNC Machines

G-code and M-code are the primary programming languages used to control CNC machines:

l G-code (Geometric code) defines the machine's movements, such as tool paths, feed rates, and spindle speeds

l M-code (Miscellaneous code) controls auxiliary functions, such as coolant, tool changes, and program stops

Example G-code commands:

l G00: Rapid positioning

l G01: Linear interpolation

l G02/G03: Circular interpolation (clockwise/counterclockwise)

l G90/G91: Absolute/incremental positioning

Example M-code commands:

l M03/M04: Spindle on (clockwise/counterclockwise)

l M05: Spindle stop

l M08/M09: Coolant on/off

l M30: Program end and reset

CNC Precision Machining Simulation and Verification Software

Simulation and verification software allows programmers and operators to validate tool paths, detect potential issues, and optimize machining processes before running them on actual CNC machines. Benefits of using simulation software include:

1. Reduced setup times and increased machine utilization

2. Minimized risk of tool crashes and machine damage

3. Improved part quality and reduced scrap rates

4. Enhanced collaboration between programmers and operators

Examples of CNC simulation and verification software:

l Vericut

l CAMWorks Virtual Machine

l Mastercam Simulator

l Siemens NX CAM Integrated Simulation

Importance of Skilled CNC Programmers and Operators

Skilled CNC programmers and operators are vital for maximizing the potential of CNC precision machining:

l Programmers must have a deep understanding of CAD/CAM software, G-code and M-code, and machining processes

l Operators should be knowledgeable about CNC machine setup, tool management, and quality control procedures

l Continuous training and education are essential to stay current with the latest technologies and best practices

Role | Key Responsibilities |

CNC Programmer | Creating and optimizing CNC programs using CAD/CAM software |

CNC Operator | Setting up and operating CNC machines, monitoring process quality |

Investing in skilled personnel and providing ongoing training is crucial for organizations seeking to achieve the highest levels of precision, efficiency, and quality in their CNC machining operations.

Applications of CNC Precision Machining

CNC precision machining has become an essential manufacturing process across various industries, enabling the production of high-quality, complex, and accurate components. Its versatility and reliability have made it indispensable in numerous sectors, from aerospace to medical devices.

Aerospace and Aviation Industry

The aerospace and aviation industry relies heavily on CNC precision machining for the production of critical components, such as:

l Turbine blades and engine parts

l Landing gear components

l Structural elements (ribs, spars, and frames)

l Fuel system components

l Avionics housings and mounts

CNC machining's ability to achieve tight tolerances and work with high-performance materials, such as titanium and Inconel, makes it ideal for the demanding requirements of the aerospace sector.

Medical Device Manufacturing

CNC precision machining plays a vital role in the production of medical devices and implants, ensuring the highest levels of accuracy and quality. Applications include:

l Orthopedic implants (hip, knee, and spinal implants)

l Surgical instruments and tools

l Dental implants and prosthetics

l Diagnostic equipment components

l Microfluidic devices and lab-on-a-chip technology

The biocompatibility and precision of CNC-machined components are crucial for patient safety and the effectiveness of medical treatments.

Automotive Industry

The automotive industry leverages CNC precision machining for the production of a wide range of components, such as:

l Engine parts (pistons, valves, and cylinder heads)

l Transmission components (gears and shafts)

l Suspension and brake system components

l Fuel injection systems

l Body and chassis parts

CNC machining's ability to efficiently produce high-quality parts with consistent tolerances is essential for the automotive sector's high-volume production requirements.

Electronics and Semiconductor Industry

CNC precision machining is crucial for the production of components used in the electronics and semiconductor industry, including:

l Heatsinks and thermal management components

l Enclosures and housings

l Connectors and contacts

l Printed Circuit Board (PCB) manufacturing equipment

l Wafer handling and inspection systems

The miniaturization and high-precision requirements of electronic components make CNC machining an indispensable process in this industry.

Defense and Military Applications

CNC precision machining is widely used in the defense and military sector for the production of:

l Weapons components (gun parts, ammunition casings)

l Aerospace and UAV components

l Armor and protective equipment

l Communication and surveillance equipment

l Optical and targeting systems

The ruggedness, reliability, and precision of CNC-machined components are critical for the performance and safety of military equipment.

Energy and Power Generation

CNC precision machining is essential for the production of components used in various energy and power generation applications, such as:

l Gas turbine components

l Wind turbine gearboxes and shafts

l Solar panel mounting systems

l Hydroelectric turbine parts

l Nuclear reactor components

The ability to machine large, complex, and high-precision components makes CNC machining a vital process in the energy sector.

Industry | Key Applications |

Aerospace and Aviation | Turbine blades, landing gear, structural components |

Medical Device Manufacturing | Orthopedic implants, surgical instruments, dental prosthetics |

Automotive | Engine parts, transmission components, brake systems |

Electronics and Semiconductor | Heatsinks, enclosures, PCB manufacturing equipment |

Defense and Military | Weapons components, aerospace parts, communication equipment |

Energy and Power Generation | Gas turbine parts, wind turbine gearboxes, nuclear reactor components |

The versatility and precision of CNC machining make it an essential process across these diverse industries, enabling the production of high-quality, reliable components that meet the most demanding performance and safety requirements.

Designing for CNC Precision Machining

Effective design is crucial for successful CNC precision machining. By following best practices and considering key factors, designers can create parts that are optimized for manufacturability, quality, and cost-effectiveness.

Design Guidelines and Best Practices

When designing parts for CNC precision machining, adhere to the following guidelines:

1. Avoid sharp corners and edges; use fillets and chamfers instead

2. Maintain uniform wall thicknesses to prevent warping and distortion

3. Minimize the use of deep pockets or cavities to reduce tool wear

4. Design for simplicity, avoiding unnecessary complexity

5. Use standard hole sizes and thread dimensions when possible

6. Consider the limitations of the CNC machine and tooling

Considerations for Tolerances, Surface Finishes, and Material Selection

Designers must take into account several critical factors when creating parts for CNC precision machining:

l Tolerances: Specify tolerances that are appropriate for the application and the capabilities of the CNC machine. Tighter tolerances may increase machining time and cost.

l Surface finishes: Define the required surface finish based on the part's function and aesthetics. Smoother finishes may require additional machining operations or post-processing.

l Material selection: Choose materials that balance performance, machinability, and cost. Consider factors such as strength, durability, thermal stability, and chemical resistance.

Factor | Considerations |

Tolerances | Application requirements, CNC machine capabilities |

Surface Finishes | Part function, aesthetics, additional processing |

Material Selection | Performance, machinability, cost, material properties |

Optimizing Designs for CNC Precision Machining Efficiency

To maximize the efficiency and cost-effectiveness of CNC precision machining, designers should:

1. Minimize the number of setups required by designing parts that can be machined in a single setup

2. Reduce tool changes by using common tool sizes and minimizing the variety of features

3. Optimize tool paths to minimize machining time and tool wear

4. Incorporate features that facilitate workholding and fixturing

5. Design for ease of chip evacuation and coolant flow

By optimizing designs for CNC machining efficiency, manufacturers can reduce cycle times, increase tool life, and improve overall productivity.

Collaboration Between Design and Manufacturing Teams

Effective collaboration between design and manufacturing teams is essential for successful CNC precision machining. Best practices include:

1. Involving manufacturing engineers early in the design process to identify potential issues and opportunities for optimization

2. Using Design for Manufacturing (DFM) principles to create parts that are easy and cost-effective to produce

3. Establishing clear communication channels and feedback loops between design and manufacturing teams

4. Utilizing CAD/CAM software to simulate and validate machining processes before production

5. Continuously monitoring and analyzing manufacturing data to identify areas for improvement and refine designs

By fostering a collaborative environment and leveraging the expertise of both design and manufacturing teams, organizations can create parts that are optimized for CNC precision machining, resulting in higher quality, lower costs, and faster time-to-market.

Choosing a CNC Precision Machining Service Provider

Selecting the right CNC precision machining service provider is crucial for the success of your project. A reliable partner can ensure high-quality parts, on-time delivery, and cost-effectiveness. Consider the following factors when choosing a CNC precision machining company.

Factors to Consider When Selecting a CNC Precision Machining Partner

1. Technical capabilities and equipment: Ensure the provider has the necessary machines, tools, and technologies to meet your project requirements.

2. Industry experience and expertise: Look for a partner with a proven track record in your specific industry or application.

3. Quality management systems: Choose a provider with robust quality control processes and certifications, such as ISO 9001, AS9100, or IATF 16949.

4. Capacity and scalability: Verify that the company can handle your production volumes and scale up as your needs grow.

5. Location and logistics: Consider the provider's proximity to your facility and their ability to manage shipping and logistics efficiently.

Evaluating Capabilities, Experience, and Quality Certifications

When evaluating potential CNC precision machining partners, ask for:

1. Machine list and specifications

2. List of materials and tolerances they can work with

3. Sample parts or case studies demonstrating their capabilities

4. Quality certifications and audit results

5. References from existing customers in your industry

Importance of Communication and Customer Support

Effective communication and customer support are essential for a successful partnership. Look for a CNC precision machining service provider that offers:

1. Dedicated project management and a single point of contact

2. Regular progress updates and transparent communication

3. Flexibility and responsiveness to changes in your requirements

4. Technical support and problem-solving capabilities

5. Collaborative approach to design for manufacturability (DFM) and process optimization

Communication Channel | Purpose |

Project Manager | Oversees project timeline, budget, and deliverables |

Technical Support | Provides guidance on design, materials, and process optimization |

Quality Control | Ensures parts meet specifications and quality standards |

Logistics | Manages shipping, packaging, and delivery of finished parts |

Cost Considerations and ROI Analysis

While cost is an important factor, it should not be the sole basis for selecting a CNC precision machining service provider. Consider the following when evaluating costs:

1. Total cost of ownership (TCO), including material, labor, tooling, and shipping costs

2. Value-added services, such as design support, assembly, or finishing operations

3. Cost savings from process optimizations and efficiency improvements

4. Return on investment (ROI) based on part quality, performance, and lifecycle costs

Conduct a thorough ROI analysis to compare the costs and benefits of different CNC precision machining service providers. This will help you make an informed decision that balances short-term costs with long-term value.

Unlock precision and innovation with TEAM MFG's CNC machining expertise. Our state-of-the-art equipment, skilled technicians, and commitment to quality ensure your projects are delivered on time, within budget, and to the highest standards. Get Precision Manufacturing Solutions Today - TEAM MFG