Since the inception of the automotive industry in the late 19th century, manufacturing advances have been the driving force behind its growth and success. From the introduction of the assembly line by Henry Ford in 1913 to the rise of automation in recent decades, the automotive industry has continually evolved to meet the demands of a changing world.

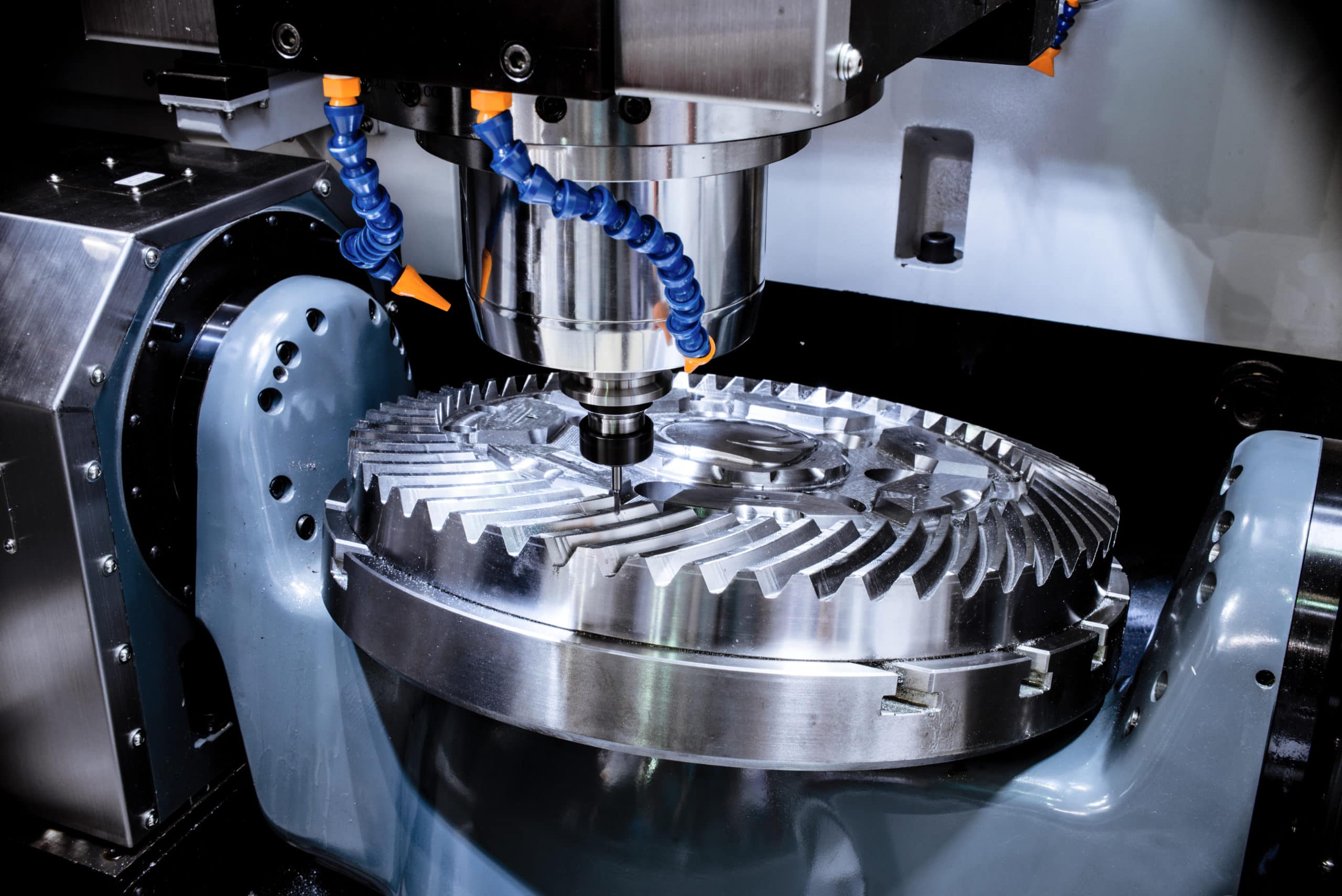

Today, CNC machining has emerged as a crucial component in modern automotive manufacturing, enabling the production of high-quality, precise, and complex parts with unparalleled efficiency and repeatability.

This article will explore the vital role CNC machining plays in the automotive industry and how it has revolutionized the way vehicles are produced.

What is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that employs computerized controls and cutting tools to remove material from a workpiece, creating custom-designed parts with high accuracy and repeatability. This technology has revolutionized the automotive industry by enabling the production of complex, high-quality components in a cost-effective and efficient manner.

How CNC Machines Work

CNC machines operate by following a set of pre-programmed instructions, known as G-code, which guide the cutting tools to remove material from the workpiece in a precise and controlled manner. The process involves the following steps:

1. Design: Engineers create a 3D model of the desired part using CAD (Computer-Aided Design) software.

2. G-Code Generation: The CAD model is then converted into G-code using CAM (Computer-Aided Manufacturing) software.

3. Setup: The workpiece is securely clamped onto the CNC machine, and the appropriate cutting tools are installed.

4. Execution: The CNC machine reads the G-code and executes the programmed motions, removing material from the workpiece as specified.

5. Finishing: Once the machining process is complete, the finished part is removed from the machine, inspected, and any necessary post-processing (such as cleaning or surface treatments) is performed.

Types of CNC Machines Used in the Automotive Industry

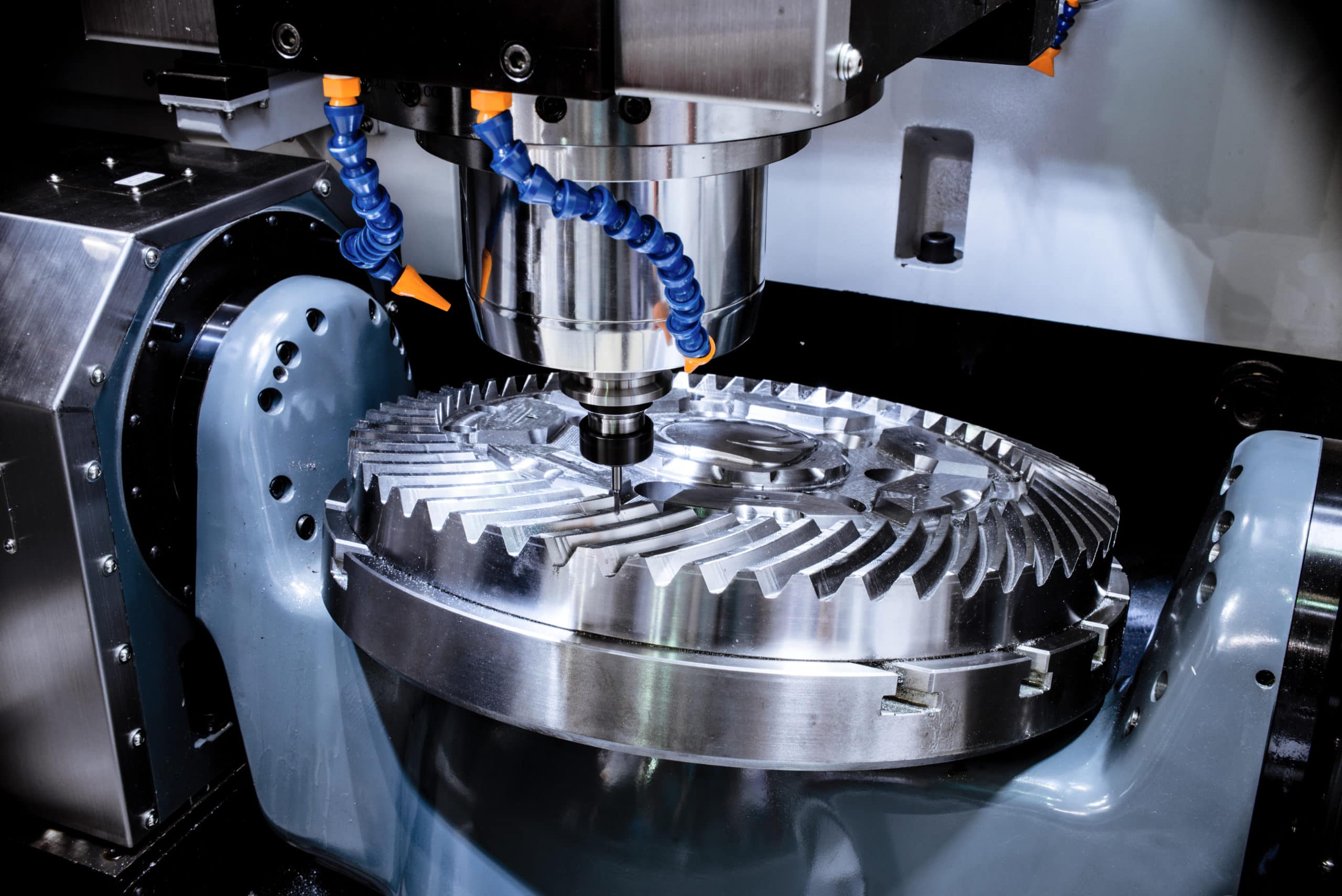

The automotive industry relies on a variety of CNC machines to produce the numerous components required for vehicle manufacturing. Some of the most common types include:

1. CNC Milling Machines: These machines use rotary cutting tools to remove material from the workpiece, creating features such as holes, slots, and pockets. They are ideal for producing engine components, transmission parts, and suspension components.

2. CNC Turning Machines: Also known as CNC lathes, these machines rotate the workpiece while a cutting tool removes material, creating cylindrical parts such as shafts, bushings, and bearings.

3. CNC Grinding Machines: These machines use abrasive wheels to remove small amounts of material from the workpiece, achieving extremely tight tolerances and smooth finishes. They are commonly used for producing transmission gears, camshafts, and other high-precision components.

4. CNC Laser Cutting Machines: These machines use high-powered lasers to cut, drill, or engrave materials, making them ideal for producing intricate sheet metal components, such as body panels and interior trim pieces.

By leveraging the capabilities of these diverse CNC machines, automotive manufacturers can produce a wide range of components with unparalleled precision, efficiency, and repeatability, ultimately leading to higher-quality vehicles and more streamlined production processes.

Advantages of CNC Machining for the Automotive Industry

CNC machining has become an indispensable tool in the automotive industry, offering numerous advantages that have revolutionized the manufacturing process. From precision and accuracy to automation and cost-effectiveness, CNC machining has proven to be a game-changer for automotive manufacturers.

Precision and Accuracy

One of the most significant advantages of CNC machining is its ability to produce parts with exceptional precision and accuracy. This is crucial in the automotive industry, where even the slightest deviation can have severe consequences on vehicle performance and safety.

1. Tight Tolerances: CNC machines can achieve tolerances as tight as ±0.0001 inches, ensuring that parts fit together perfectly and function as intended.

2. Consistency in Part Production: CNC machining guarantees consistent results across multiple production runs, reducing the risk of manufacturing errors and ensuring that every part meets the same high standards.

Automation and Efficiency

CNC machining is a highly automated process, which translates to increased efficiency and productivity in the automotive manufacturing sector.

1. Reduced Labor Costs: By automating the machining process, manufacturers can significantly reduce labor costs associated with manual machining operations.

2. Faster Production Times: CNC machines can operate at high speeds and with minimal downtime, enabling manufacturers to produce parts much faster than traditional machining methods.

3. 24/7 Operation: CNC machines can run continuously, 24 hours a day, 7 days a week, maximizing production output and minimizing lead times.

Flexibility and Adaptability

CNC machining offers unparalleled flexibility and adaptability, allowing automotive manufacturers to quickly respond to changing market demands and produce a wide range of components.

1. Ability to Produce Complex Geometries: CNC machines can easily handle complex part geometries, including intricate curves, angles, and contours, making them ideal for producing advanced automotive components.

2. Quick Tooling Changes: CNC machines allow for rapid tooling changeovers, enabling manufacturers to switch between different part designs and materials with minimal downtime.

3. Compatibility with Various Materials: CNC machining is compatible with a wide range of materials, including metals, plastics, and composites, giving automotive manufacturers the flexibility to choose the best material for each application.

Cost-Effectiveness

Despite the initial investment in CNC machines, the technology offers significant cost savings in the long run, making it an attractive option for automotive manufacturers.

1. Reduced Waste Material: CNC machining is a highly efficient process that minimizes waste material, reducing overall material costs and environmental impact.

2. Longer Tool Life: CNC machines use advanced cutting tools and optimized toolpaths, which can extend tool life and reduce tooling costs over time.

3. Lower Production Costs for High-Volume Parts: CNC machining is particularly cost-effective for high-volume production runs, as the initial setup costs are spread out over a larger number of parts.

By leveraging the precision, efficiency, flexibility, and cost-effectiveness of CNC machining, automotive manufacturers can produce higher-quality components, streamline their production processes, and remain competitive in an ever-evolving industry.

Applications of CNC Machining in the Automotive Industry

CNC machining plays a crucial role in the production of a wide range of automotive components, from engine parts to suspension systems. Its precision, efficiency, and versatility make it an indispensable tool for manufacturers looking to create high-quality, reliable parts. In this section, we will explore some of the key applications of CNC machining in the automotive industry.

Engine Components

The engine is the heart of any vehicle, and CNC machining is essential in producing many of its critical components. Here are a few examples:

1. Cylinder Heads: CNC machining is used to create the complex geometries and precise features of cylinder heads, such as valve seats, spark plug holes, and coolant passages. The accuracy and consistency achieved through CNC machining ensure optimal engine performance and efficiency.

2. Engine Blocks: CNC machining is employed to create the intricate internal geometries of engine blocks, including cylinder bores, main bearing caps, and oil passages. The high precision and repeatability of CNC machining guarantee that the engine block meets the required tolerances for smooth operation and longevity.

3. Pistons and Connecting Rods: These critical moving parts within the engine are produced using CNC machining to ensure the necessary precision and durability. Pistons are often machined from aluminum alloys, while connecting rods are typically made from forged steel. The accurate machining of these components is crucial for proper fit, balance, and performance.

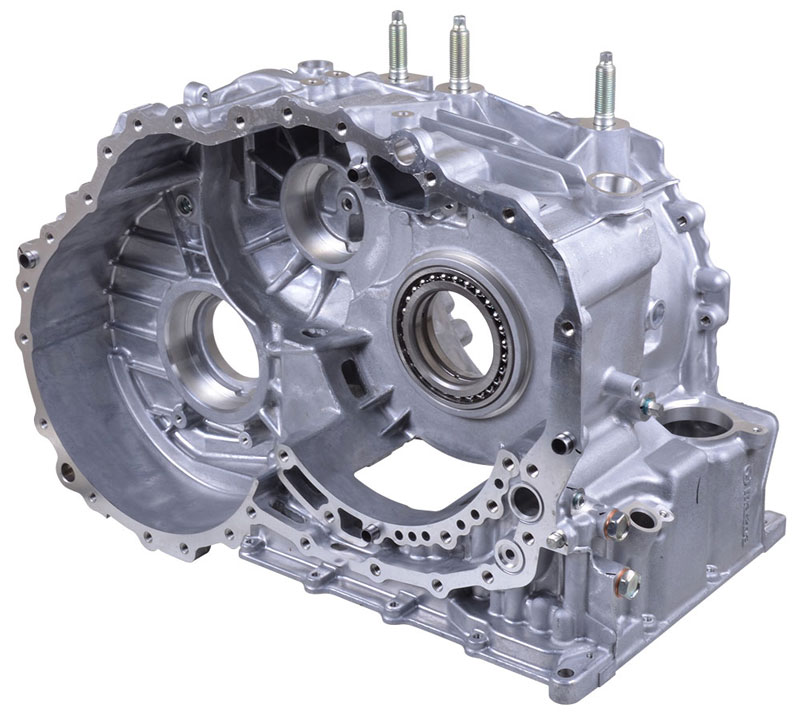

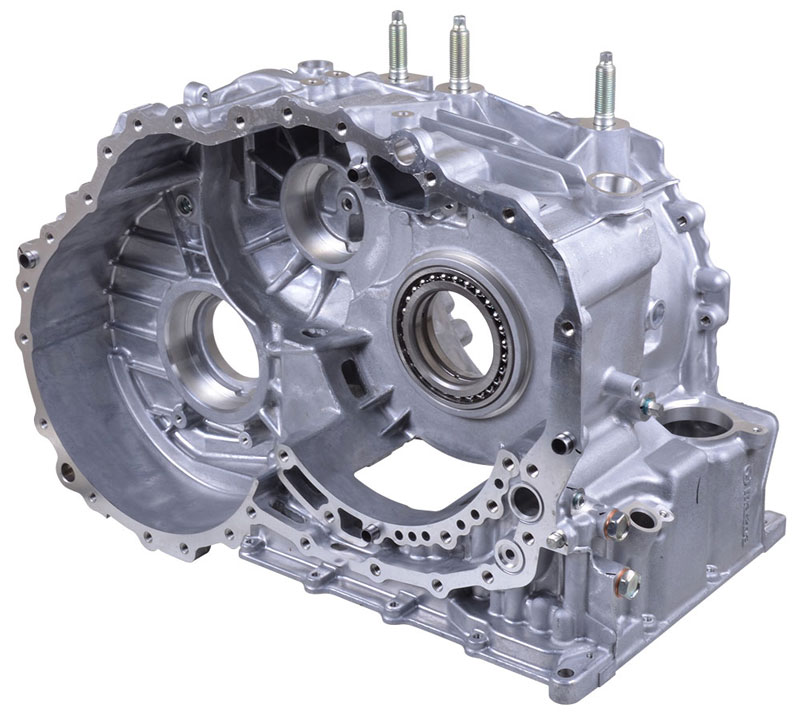

Transmission Parts

CNC machining plays a critical role in the production of transmission components, which are essential for transferring power from the engine to the wheels. The precision and accuracy achieved through CNC machining ensure that these parts function seamlessly, providing smooth and efficient vehicle operation. Here are some key transmission components produced using CNC machining:

1. Gears: Transmission gears are complex components that require precise tooth profiles and geometries to ensure smooth and efficient power transfer. CNC machining is ideal for creating these intricate shapes, as it can achieve tight tolerances and consistent results. The accuracy of CNC-machined gears is crucial for reducing noise, vibration, and wear within the transmission.

2. Shafts: Transmission shafts, such as input and output shafts, are critical components that transmit torque between gears and other transmission parts. CNC machining is used to create these shafts with the required dimensions, surface finishes, and features like splines and keyways. The precision of CNC-machined shafts ensures proper alignment and balance within the transmission, reducing vibration and extending the lifespan of the components.

3. Housing: The transmission housing is a complex component that encases and supports the various gears, shafts, and bearings within the transmission. CNC machining is used to create the intricate internal geometries and precise mounting surfaces of the housing. The accuracy of CNC machining ensures that all transmission components fit perfectly within the housing, allowing for optimal performance and durability.

By utilizing CNC machining for the production of transmission parts, automotive manufacturers can achieve several benefits:

l Improved efficiency and performance

l Reduced noise and vibration

l Extended component lifespan

l Consistent and reliable operation

The precision and accuracy of CNC-machined transmission components contribute to the overall quality and performance of the vehicle, providing a better driving experience for consumers.

Suspension Components

CNC machining is extensively used in the production of suspension components, which play a vital role in ensuring vehicle stability, handling, and ride comfort. The precision and durability of CNC-machined suspension parts contribute to the overall safety and performance of the vehicle. Here are some key suspension components produced using CNC machining:

1. Control Arms: Control arms are critical suspension components that connect the vehicle's frame or subframe to the steering knuckle, allowing for wheel movement and alignment. CNC machining is used to create control arms with the necessary strength, stiffness, and precise geometry. The accuracy of CNC machining ensures that the control arms fit perfectly and provide optimal wheel alignment and control.

2. Knuckles: Steering knuckles, also known as spindles, are the components that connect the wheel hub to the control arms and allow for wheel rotation and steering. CNC machining is used to create the complex geometries and precise mounting points of the knuckles. The accuracy of CNC-machined knuckles ensures proper wheel alignment and smooth steering operation.

3. Hubs: Wheel hubs are the central components that connect the wheel and brake rotor to the vehicle's suspension and drivetrain. CNC machining is used to create the precise bore and mounting surfaces of the hubs, ensuring a perfect fit with the bearings and other components. The accuracy and durability of CNC-machined hubs are crucial for maintaining wheel alignment and reducing vibration.

The benefits of using CNC machining for the production of suspension components include:

l Improved handling and stability

l Reduced vibration and noise

l Extended component lifespan

l Consistent and reliable performance

By ensuring the precision and durability of suspension components, CNC machining contributes to the overall safety, comfort, and performance of the vehicle. This, in turn, provides a better driving experience for consumers and helps automotive manufacturers maintain their competitive edge in the market.

Brake System Components

CNC machining plays a critical role in the production of brake system components, which are essential for ensuring vehicle safety and performance. The precision and reliability of CNC-machined brake parts contribute to the overall braking efficiency and responsiveness of the vehicle. Here are some key brake system components produced using CNC machining:

1. Brake Calipers: Brake calipers are the components that house the brake pads and apply pressure to the brake rotor, causing the vehicle to slow down or stop. CNC machining is used to create the complex geometries and precise bore surfaces of the calipers, ensuring proper fitment and smooth operation. The accuracy of CNC-machined calipers is crucial for maintaining consistent braking performance and reducing brake fade.

2. Brake Rotors: Brake rotors, also known as brake discs, are the rotating components that the brake pads clamp onto to generate friction and slow the vehicle. CNC machining is used to create the precise surfaces and cooling vanes of the rotors, ensuring efficient heat dissipation and consistent braking performance. The accuracy of CNC-machined rotors is essential for minimizing brake vibration and ensuring even wear of the brake pads.

3. Master Cylinders: The master cylinder is the heart of the brake system, responsible for converting the force applied to the brake pedal into hydraulic pressure that actuates the brake calipers. CNC machining is used to create the precise bore and piston surfaces of the master cylinder, ensuring efficient and reliable operation. The accuracy of CNC-machined master cylinders is crucial for maintaining consistent brake pedal feel and braking performance.

The benefits of using CNC machining for the production of brake system components include:

l Improved braking performance and efficiency

l Reduced brake fade and vibration

l Extended component lifespan

l Consistent and reliable braking operation

By ensuring the precision and reliability of brake system components, CNC machining contributes to the overall safety and performance of the vehicle. This, in turn, provides peace of mind for consumers and helps automotive manufacturers maintain their reputation for producing high-quality, safe vehicles.

Steering System Components

CNC machining is extensively used in the production of steering system components, which are crucial for ensuring precise and responsive vehicle handling. The accuracy and durability of CNC-machined steering parts contribute to the overall safety and performance of the vehicle. Here are some key steering system components produced using CNC machining:

1. Steering Rack and Pinion: The steering rack and pinion is the heart of the steering system, responsible for converting the rotational motion of the steering wheel into the linear motion that turns the wheels. CNC machining is used to create the precise gear teeth and housing surfaces of the rack and pinion, ensuring smooth and accurate steering operation. The accuracy of CNC-machined rack and pinion assemblies is crucial for maintaining precise steering control and reducing steering play.

2. Steering Column: The steering column is the component that connects the steering wheel to the steering rack, transmitting the driver's input to the wheels. CNC machining is used to create the precise bearing surfaces and mounting points of the steering column, ensuring smooth rotation and reducing vibration. The accuracy of CNC-machined steering columns is essential for maintaining precise steering feel and minimizing steering shaft flex.

3. Tie Rods: Tie rods are the components that connect the steering rack to the steering knuckles, transmitting the steering force to the wheels. CNC machining is used to create the precise threading and ball joint surfaces of the tie rods, ensuring accurate wheel alignment and smooth steering operation. The accuracy of CNC-machined tie rods is crucial for maintaining precise steering geometry and reducing tire wear.

The benefits of using CNC machining for the production of steering system components include:

l Improved steering precision and responsiveness

l Reduced steering play and vibration

l Extended component lifespan

l Consistent and reliable steering performance

By ensuring the accuracy and durability of steering system components, CNC machining contributes to the overall safety, handling, and performance of the vehicle. This, in turn, provides a more enjoyable and confident driving experience for consumers and helps automotive manufacturers maintain their competitive edge in the market.

Interior and Exterior Trim Parts

CNC machining is widely used in the production of interior and exterior trim parts, which contribute to the aesthetic appeal, comfort, and functionality of the vehicle. The precision and versatility of CNC machining allow for the creation of complex shapes and intricate details that enhance the overall quality and appearance of the vehicle. Here are some key interior and exterior trim parts produced using CNC machining:

1. Dashboard Components: CNC machining is used to create various dashboard components, such as instrument panels, center consoles, and air vents. The precision of CNC machining allows for the creation of complex shapes, tight tolerances, and smooth surfaces that seamlessly integrate with the vehicle's interior design. CNC-machined dashboard components not only enhance the visual appeal but also ensure proper fitment and functionality of the various controls and displays.

2. Door Handles and Panels: CNC machining is used to produce door handles, door panels, and other interior trim components. The accuracy and consistency of CNC machining ensure that these parts fit perfectly and operate smoothly, providing a high-quality feel to the vehicle's interior. CNC-machined door handles and panels can be created with intricate designs, textured surfaces, and precise mounting points, enhancing both the aesthetics and functionality of the vehicle's doors.

3. Grilles and Emblems: CNC machining is used to create exterior trim parts such as grilles and emblems, which are critical elements of a vehicle's front fascia. The precision and versatility of CNC machining allow for the creation of intricate and distinctive designs that showcase the vehicle's brand identity. CNC-machined grilles and emblems can be produced with tight tolerances, ensuring a perfect fit and alignment with the surrounding bodywork. These parts not only enhance the vehicle's aesthetic appeal but also contribute to its aerodynamic performance and cooling efficiency.

The benefits of using CNC machining for the production of interior and exterior trim parts include:

l Enhanced visual appeal and brand identity

l Improved fitment and functionality

l Consistent and high-quality appearance

l Ability to create complex shapes and intricate details

By ensuring the precision, quality, and aesthetic appeal of interior and exterior trim parts, CNC machining contributes to the overall customer satisfaction and perception of the vehicle. This, in turn, helps automotive manufacturers differentiate their products and maintain their competitive edge in the market.

CNC Machining Materials for the Automotive Industry

The automotive industry relies on a wide range of materials to produce high-quality, durable, and performance-oriented components. CNC machining is compatible with many of these materials, allowing manufacturers to create parts with specific properties tailored to their applications.

Metals

Metals are the most widely used materials in the automotive industry due to their strength, durability, and versatility. CNC machining is well-suited for processing various metal alloys, enabling the creation of complex geometries and precise tolerances. Here are some of the most common metal alloys used in CNC machining for automotive applications:

1. Aluminum Alloys: Aluminum alloys are lightweight, corrosion-resistant, and offer excellent machinability. They are commonly used for engine components, suspension parts, and body panels. Popular aluminum alloys for automotive CNC machining include:

a. 6061: Known for its excellent balance of strength, corrosion resistance, and machinability.

b. 7075: Offers high strength and wear resistance, making it suitable for structural and load-bearing components.

2. Steel Alloys: Steel alloys are renowned for their strength, toughness, and durability. They are used in various automotive applications, including drivetrain components, suspension parts, and fasteners. Common steel alloys for CNC machining include:

a. 4140: A chromium-molybdenum alloy with high tensile strength and fatigue resistance, often used for gears and shafts.

b. 1045: A medium carbon steel with good machinability and wear resistance, suitable for brackets and fixtures.

3. Titanium Alloys: Titanium alloys offer an exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance. They are used in high-performance applications, such as engine valves, connecting rods, and turbocharger components. The most common titanium alloy for automotive CNC machining is:

a. Ti-6Al-4V: Known for its high strength, light weight, and excellent fatigue resistance.

4. Magnesium Alloys: Magnesium alloys are the lightest structural metals, offering excellent strength-to-weight ratios and good machinability. They are used in applications where weight reduction is critical, such as engine blocks, transmission cases, and steering wheel frames. Common magnesium alloys for CNC machining include:

a. AZ91D: Offers good castability, strength, and corrosion resistance.

b. AM60B: Known for its excellent ductility, impact resistance, and machinability.

Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability |

Aluminum (6061-T6) | 2.70 | 310 | Excellent |

Steel (4140) | 7.85 | 655 | Good |

Titanium (Ti-6Al-4V) | 4.43 | 950 | Fair |

Magnesium (AZ91D) | 1.81 | 230 | Excellent |

Plastics

In addition to metals, plastics are increasingly used in the automotive industry for various applications, ranging from interior trim components to functional parts. CNC machining is well-suited for processing engineering plastics, offering the ability to create complex geometries, tight tolerances, and smooth surface finishes. Here are some of the most common plastics used in CNC machining for automotive applications:

1. ABS (Acrylonitrile Butadiene Styrene): ABS is a popular thermoplastic known for its impact resistance, toughness, and dimensional stability. It is commonly used for interior trim components, such as dashboard panels, console covers, and air vents. ABS offers good machinability, allowing for the creation of intricate designs and smooth surfaces.

2. Nylon: Nylon is a versatile engineering plastic with excellent mechanical properties, including high strength, wear resistance, and low friction. It is used in various automotive applications, such as gears, bearings, and fasteners. Nylon's self-lubricating properties make it ideal for moving parts, reducing the need for additional lubrication.

3. Acetal: Acetal, also known as polyoxymethylene (POM), is a high-performance plastic with excellent dimensional stability, stiffness, and wear resistance. It is commonly used for precision automotive components, such as fuel system parts, door lock mechanisms, and window regulators. Acetal's low moisture absorption and good machinability make it suitable for tight-tolerance applications.

4. PEEK (Polyether Ether Ketone): PEEK is a high-performance thermoplastic with exceptional mechanical and thermal properties. It offers high strength, stiffness, and dimensional stability, even at elevated temperatures. PEEK is used in demanding automotive applications, such as engine components, transmission parts, and brake systems. Its excellent wear resistance and chemical resistance make it suitable for harsh environments.

Material | Density (g/cm³) | Tensile Strength (MPa) | Max. Continuous Use Temperature (°C) |

ABS | 1.04 | 44 | 85 |

Nylon 6 | 1.14 | 79 | 100 |

Acetal | 1.41 | 68 | 100 |

PEEK | 1.32 | 100 | 250 |

When selecting a plastic material for CNC machining in the automotive industry, engineers consider factors such as mechanical properties, temperature resistance, chemical resistance, and cost. The use of plastics in automotive applications offers several advantages, including weight reduction, corrosion resistance, and electrical insulation.

By leveraging the capabilities of CNC machining and the properties of these engineering plastics, automotive manufacturers can produce lightweight, durable, and precision-engineered components that enhance vehicle performance, efficiency, and comfort.

Composites

Composite materials are increasingly being used in the automotive industry due to their unique combination of properties, such as high strength-to-weight ratios, corrosion resistance, and design flexibility. CNC machining plays a crucial role in the processing of composite components, enabling the creation of complex shapes and precise features. Here are two of the most common composite materials used in CNC machining for automotive applications:

1. Carbon Fiber Reinforced Plastics (CFRP): CFRP is a high-performance composite material consisting of carbon fibers embedded in a polymer matrix. It offers exceptional strength-to-weight ratios, stiffness, and fatigue resistance. CFRP is used in various automotive applications, including:

a. Structural components: Chassis, suspension arms, and roll cages.

b. Exterior body panels: Hood, roof, and trunk lids.

c. Interior trim: Dashboard, seat frames, and steering wheels.

CNC machining is used to trim, drill, and mill CFRP components, ensuring precise dimensions and smooth surfaces. However, machining CFRP requires specialized tools and techniques to minimize delamination and fiber pullout.

2. Glass Fiber Reinforced Plastics (GFRP): GFRP is a composite material consisting of glass fibers embedded in a polymer matrix. It offers good strength-to-weight ratios, electrical insulation, and corrosion resistance. GFRP is used in various automotive applications, such as:

a. Body panels: Fenders, door skins, and spare tire covers.

b. Electrical components: Battery trays, fuse boxes, and connector housings.

c. Structural parts: Leaf springs, bumper beams, and cross members.

CNC machining is used to cut, drill, and shape GFRP components, allowing for the creation of complex geometries and tight tolerances. Machining GFRP requires careful selection of cutting tools and parameters to minimize fiber breakout and ensure a clean edge finish.

Material | Density (g/cm³) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

CFRP | 1.55 | 2000-2500 | 130-150 |

GFRP | 1.85 | 500-1000 | 20-40 |

The use of composite materials in the automotive industry offers several advantages, including weight reduction, improved fuel efficiency, and enhanced performance. However, machining composites presents unique challenges compared to metals and plastics. Proper tool selection, cutting parameters, and machining strategies are essential to ensure the quality and integrity of the machined composite components.

By leveraging the capabilities of CNC machining and the properties of these composite materials, automotive manufacturers can produce lightweight, high-strength, and precision-engineered components that push the boundaries of vehicle performance and efficiency.

The Future of CNC Machining in the Automotive Industry

As the automotive industry continues to evolve, CNC machining is poised to play an even more significant role in shaping the future of vehicle manufacturing. With advancements in technology and the rise of new trends, such as Industry 4.0, additive manufacturing, and electric and autonomous vehicles, CNC machining is adapting to meet the changing needs of the industry.

Industry 4.0 and Smart Manufacturing

Industry 4.0, also known as the Fourth Industrial Revolution, is transforming the way automotive components are manufactured. This new era of manufacturing focuses on the integration of advanced technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, to create smart factories. In the context of CNC machining, this means:

1. Integration of CNC Machines with IoT Devices: By equipping CNC machines with IoT sensors and connectivity, manufacturers can collect real-time data on machine performance, tool wear, and product quality. This data can be used to optimize machining processes, reduce downtime, and improve overall equipment effectiveness (OEE).

2. Real-Time Data Analysis for Predictive Maintenance: With the help of AI and machine learning algorithms, the data collected from IoT-enabled CNC machines can be analyzed to predict potential machine failures and schedule maintenance proactively. This predictive maintenance approach minimizes unexpected downtime, reduces maintenance costs, and improves the reliability of the manufacturing process.

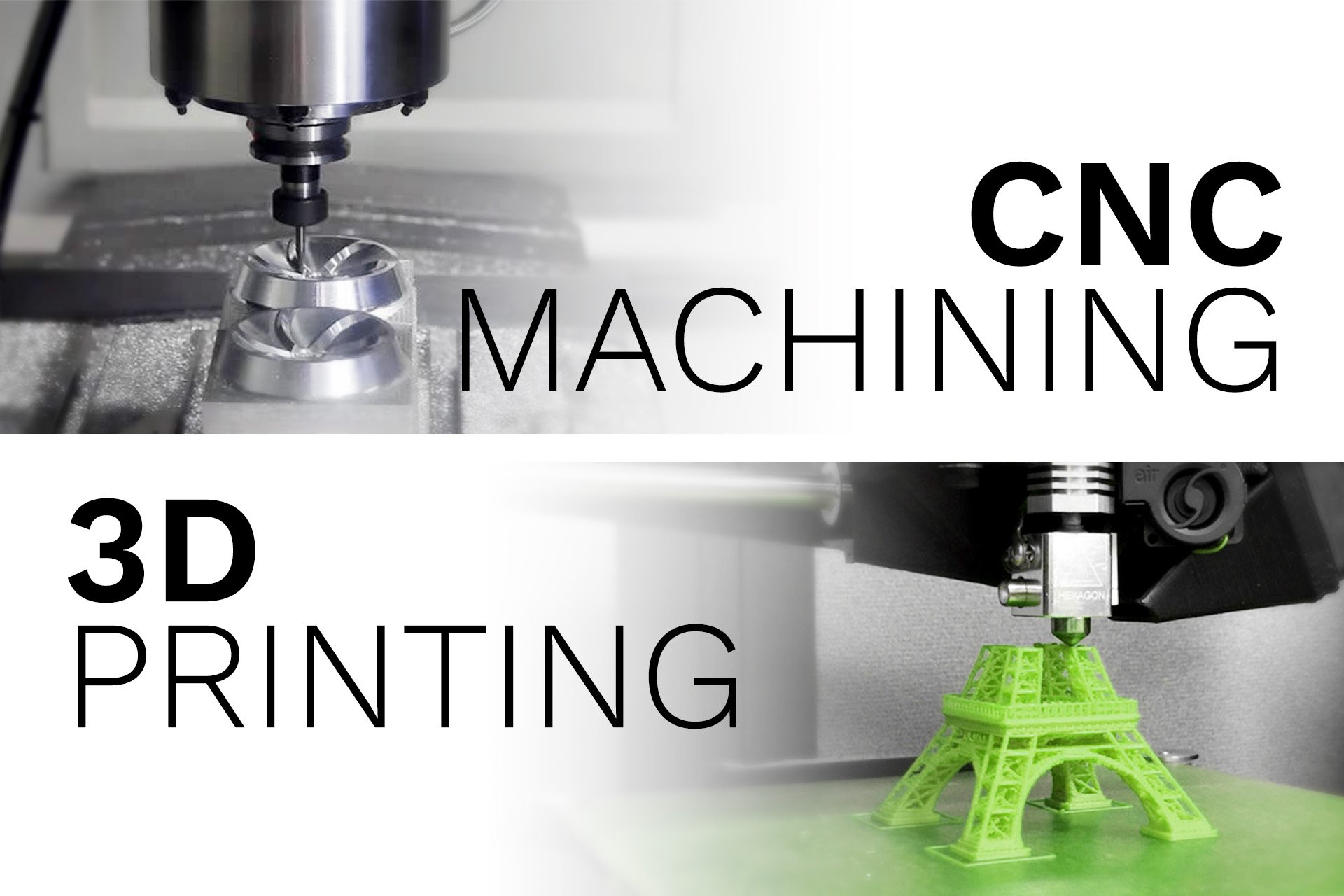

Additive Manufacturing and 3D Printing

Additive manufacturing, also known as 3D printing, is increasingly being used in the automotive industry for prototyping, tooling, and even final part production. While CNC machining remains the primary method for producing high-volume, precision components, additive manufacturing offers new possibilities for complex geometries and lightweight designs.

1. Combining CNC Machining with Additive Manufacturing: By combining the strengths of both technologies, automotive manufacturers can create hybrid parts that leverage the precision and surface finish of CNC machining with the design freedom and weight reduction of additive manufacturing. For example, a 3D-printed part can be CNC machined to achieve tight tolerances and smooth surfaces in critical areas.

2. Rapid Prototyping and Tooling: Additive manufacturing enables quick and cost-effective production of prototype parts and tooling, such as molds and fixtures. This rapid prototyping capability allows automotive engineers to iterate designs faster, validate concepts, and bring new products to market more quickly. CNC machining can then be used to refine and optimize the final design for mass production.

Electric and Autonomous Vehicles

The rise of electric and autonomous vehicles is driving new demands for lightweight components and precision-machined parts. CNC machining is adapting to meet these challenges and support the development of next-generation vehicles.

1. CNC Machining for Lightweight Components: Electric vehicles require lightweight components to maximize battery range and efficiency. CNC machining is being used to produce lightweight parts from advanced materials, such as aluminum alloys, magnesium alloys, and composites. By optimizing designs and leveraging the precision of CNC machining, manufacturers can create components that offer the best balance of strength, stiffness, and weight.

2. Precision Machining for Sensors and Electronics: Autonomous vehicles rely on a complex array of sensors, cameras, and electronic components to perceive and navigate their environment. CNC machining plays a critical role in producing the high-precision housings, brackets, and connectors that enable these systems to function reliably. As the demand for autonomous vehicle technology grows, the need for precision CNC-machined components will only increase.

The future of CNC machining in the automotive industry is bright, driven by advancements in technology, the rise of new manufacturing paradigms, and the evolving needs of next-generation vehicles. By embracing these changes and adapting to new challenges, CNC machining will continue to be a vital tool for automotive manufacturers in the years to come.

Team Mfg: Your Partner in Innovation

Custom CNC Machining Services

At Team Mfg, we offer tailored CNC machining solutions to meet the unique needs of automotive manufacturers. Our state-of-the-art facilities and expert team deliver custom parts with exceptional precision and quality. From rapid prototyping to mass production runs, we provide:

l 3, 4, and 5-axis CNC machining capabilities

l Compatible with metals, plastics, composites and more

l Fast turnaround times

l In-house design for manufacturing (DFM) support

l Rigorous quality control and inspection

Getting Started with Team Mfg

Our team is ready to bring your automotive visions to life through innovative machining solutions. Here's how to get started:

1. Contact Us: Reach out via phone, email or website form to discuss your project.

2. Design Review: Our engineers analyze your CAD models and provide DFM feedback.

3. Prototyping: We rapidly produce prototypes for design verification and testing.

4. Production: With your approval, we move to cost-effective, high-quality manufacturing.

5. Delivery: Precision auto parts are shipped directly to your facility.

Take the first step towards partnering with the machining experts at Team Mfg today!