Why has ABS (Acrylonitrile Butadiene Styrene) remained a go-to material in the 3D printing industry for over three decades? Its exceptional mechanical properties, heat resistance up to 105°C, and versatile post-processing capabilities make it an invaluable choice for makers and manufacturers alike.

Whether you're a seasoned professional or an ambitious hobbyist, understanding the nuances of ABS printing can dramatically expand your 3D printing capabilities. In this blog, we will guide you into the magical world of 3D printing with ABS filament, understanding definition, applications, and advantages in order to make better choice.

What is ABS Plastic?

Acrylonitrile Butadiene Styrene (ABS) revolutionized manufacturing industries before emerging as a cornerstone material in 3D printing technology. Its unique molecular structure, combining three distinct monomers, delivers exceptional mechanical properties. Studies indicate ABS components maintain structural integrity at temperatures up to 105°C, significantly outperforming alternative materials.

Applications of ABS 3D Printing

Industry experts recognize ABS in numerous everyday items:

Automotive components (20% market share)

Consumer electronics (35% market share)

Household appliances (25% market share)

Industrial equipment (15% market share)

Other applications (5% market share)

Industrial Manufacturing demonstrates significant adoption of ABS printing technology. Manufacturing facilities leverage ABS for:

Custom tooling and fixtures reducing production costs by 40%

Functional prototypes withstanding real-world testing conditions

Replacement parts manufactured on-demand, cutting inventory costs

Assembly line optimization tools improving efficiency by 25%

Automotive Applications showcase ABS's durability and heat resistance:

| Component Type | Usage Benefits | Performance Metrics |

| Interior Parts | Heat stable to 105°C | 95% durability rating |

| Custom Brackets | High impact resistance | 200 J/m impact strength |

| Prototype Parts | Rapid iteration | 70% time reduction |

| Service Tools | Cost-effective | 60% cost savings |

Consumer Electronics benefit from ABS's versatility:

Device enclosures with excellent impact resistance

Heat-resistant components for electronic assemblies

Custom mounting solutions

Prototype casings for product development

Medical and Healthcare applications emphasize precision: Key Applications:

Anatomical models for surgical planning

Custom medical device housings

Laboratory equipment components

Training and educational models

Architectural and Design sectors utilize ABS for:

Scale model components requiring durability

Custom architectural elements

Exhibition display pieces

Functional prototypes for building systems

Educational Projects leverage ABS's properties:

Research and Development applications include:

| Field | Application | Key Advantage |

| Material Science | Test specimens | Consistent properties |

| Engineering | Functional prototypes | Rapid iteration |

| Product Design | Concept models | Cost-effective |

| Biomedical | Custom devices | Design flexibility |

Specialized Industries find unique uses:

Aerospace component prototyping

Military equipment customization

Marine hardware development

Sports equipment modification

Advantages of 3D Printing with ABS Filament

Superior Mechanical Properties stand out as a defining characteristic of ABS printed parts. The material exhibits exceptional impact resistance, reaching up to 200 J/m, surpassing most common 3D printing materials. Its tensile strength ranges from 40-50 MPa, enabling the production of durable functional components capable of withstanding significant mechanical stress.

Outstanding Heat Resistance makes ABS an ideal choice for demanding applications. The material maintains structural integrity up to 105°C, significantly outperforming PLA (60°C) and PETG (85°C). This superior heat tolerance ensures printed parts remain stable under elevated temperatures, making them suitable for automotive components and outdoor installations.

Versatile Post-Processing Options differentiate ABS from other printing materials. The material readily responds to:

Acetone vapor smoothing, achieving injection-molded surface quality

Progressive sanding techniques, allowing fine surface control

Paint adhesion, enabling diverse finishing options

Mechanical polishing, resulting in high-gloss surfaces

Remarkable Cost-Effectiveness positions ABS as an economically viable choice. Market analysis reveals:

| Cost Factor | Value |

| Raw Material | $20-25/kg |

| Processing Time | 15% faster than PLA |

| Waste Reduction | 10% less support material |

| Post-processing Cost | 30% lower than alternatives |

Wide Application Versatility demonstrates ABS's adaptability across industries. The material excels in:

Automotive parts requiring high impact resistance

Consumer electronics housings needing heat stability

Industrial tooling and fixtures

Prototype development demanding durability

Custom manufacturing solutions

This combination of properties positions ABS as a premier choice for advanced 3D printing applications, particularly where strength, heat resistance, and cost-effectiveness are paramount considerations.

Limitations and Challenges of ABS Plastic

Temperature sensitivity metrics:

Warping threshold: 3°C/minute cooling rate

Optimal ambient temperature: 50-60°C

Critical temperature differential: <15°C

Environmental concerns include:

VOC emissions reaching 200 μg/m³ during printing

Moisture absorption rate: 0.3% per 24 hours at 50% RH

Thermal expansion coefficient: 95 × 10^-6 mm/mm/°C

Essential Equipment Setup

3D Printer Requirements

Successful ABS printing demands specific hardware configurations:

Essential components:

Heated bed (minimum 110°C capability)

Enclosed chamber (temperature variance <5°C)

All-metal hotend (rated >260°C)

Active air filtration system

Print Surface Preparation

Successful ABS adhesion requires meticulous surface preparation. Research indicates proper bed preparation can increase first-layer success rates by 85%.

Surface options comparison:

| Surface Type | Adhesion Rating | Temperature Stability | Cost Effectiveness |

| Glass + ABS Slurry | 95% | Excellent | High |

| PEI Sheet | 90% | Very Good | Medium |

| Kapton Tape | 85% | Good | Low |

| BuildTak | 80% | Good | Medium |

Key preparation steps:

Surface cleaning (isopropyl alcohol >99%)

Temperature stabilization (15-minute pre-heating)

Adhesion promoter application

Level verification (±0.05mm tolerance)

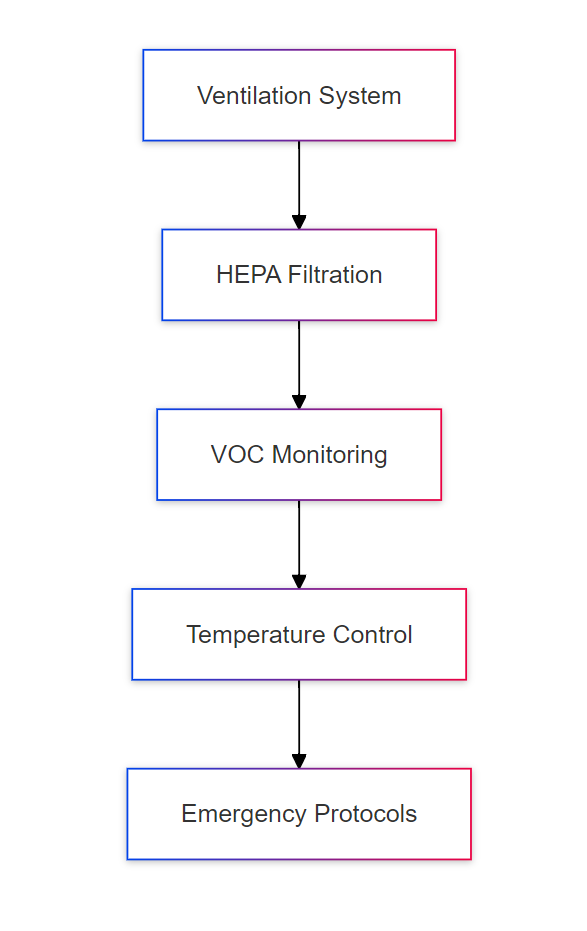

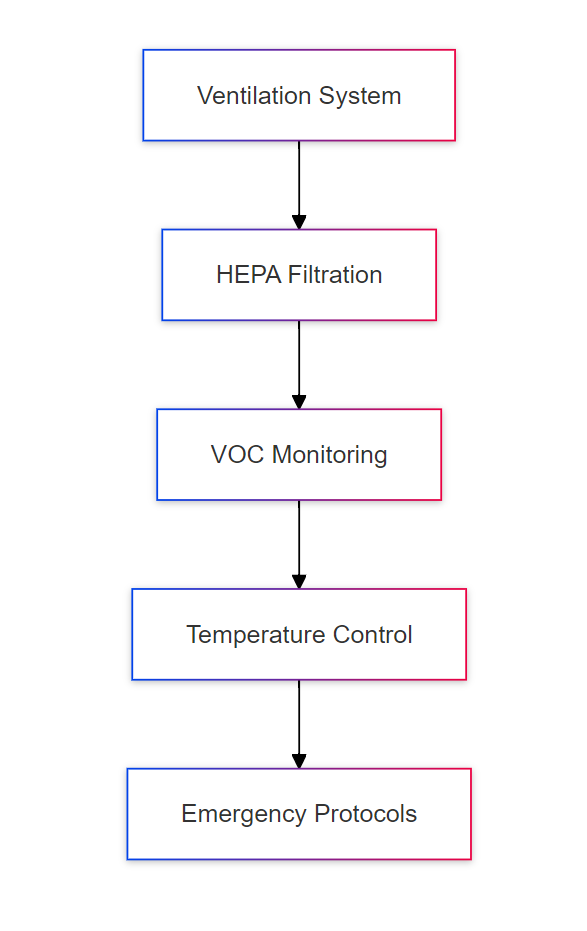

Environmental Controls

Temperature management proves crucial for ABS printing success. Studies show enclosed chambers can reduce warping by 78%.

Essential environmental parameters:

Chamber temperature: 45-50°C

Temperature gradient: <2°C/hour

Humidity range: 30-40%

Air circulation: 0.1-0.2 m/s

Printing Parameters and Settings of 3D Printing with ABS

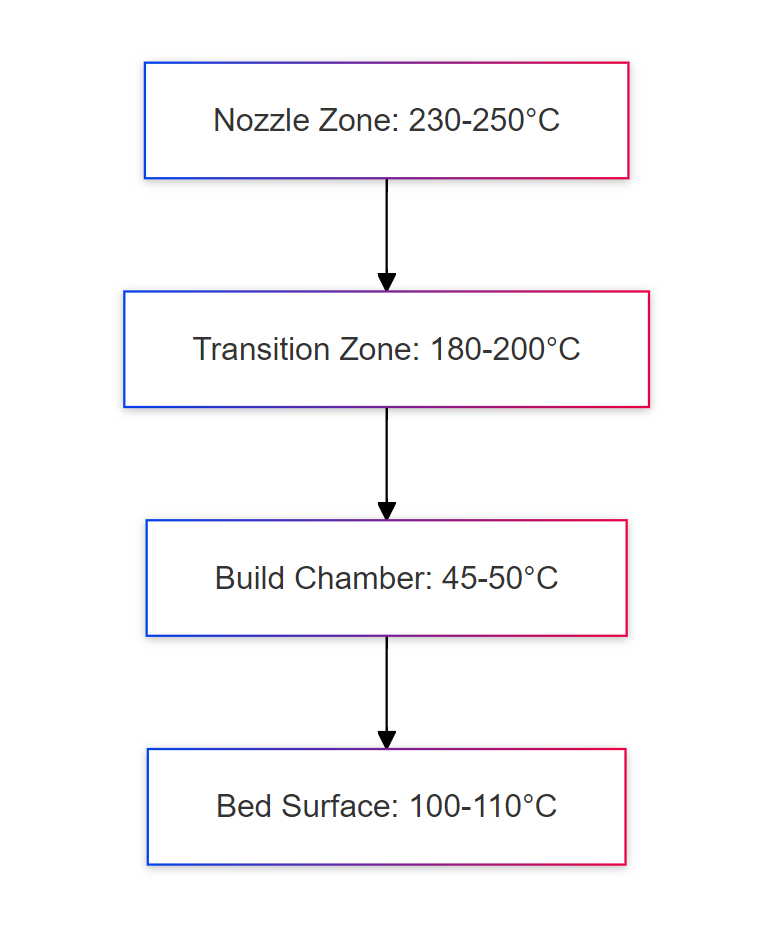

Temperature Management

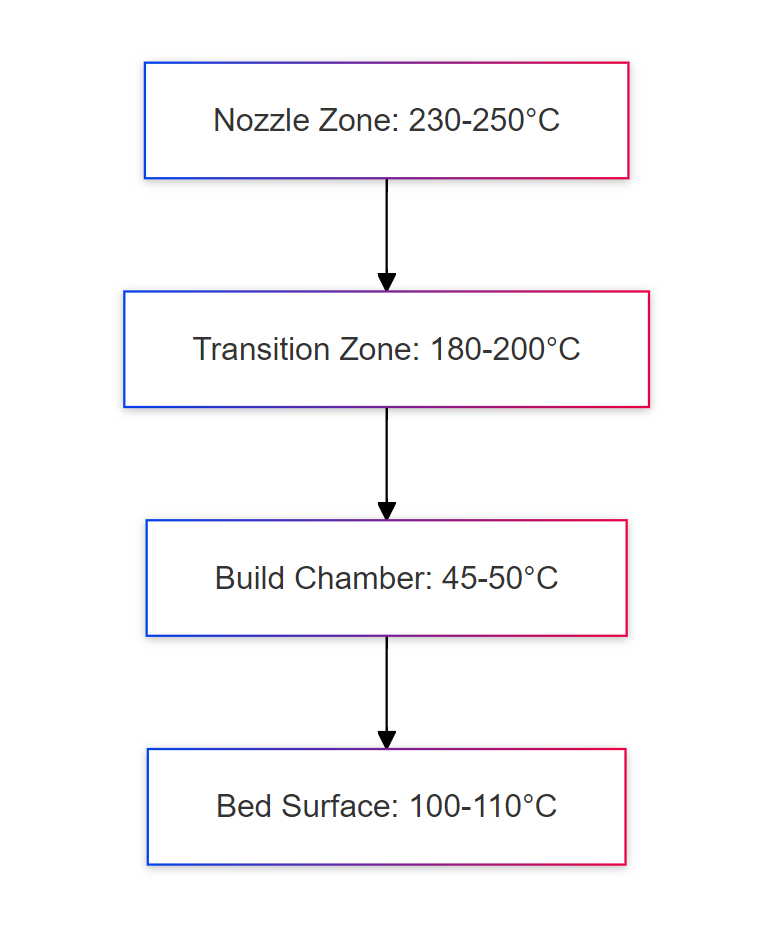

Optimal temperature control significantly impacts print quality. Research demonstrates proper temperature management can reduce defects by 65%.

Temperature zones:

Critical factors:

Nozzle temperature stability (±2°C)

Bed temperature uniformity (±3°C)

Chamber temperature consistency

Thermal gradient management

Print Settings

Empirical testing reveals optimal print parameters for ABS:

| Parameter | Recommended Range | Impact on Quality |

| Print Speed | 30-50 mm/s | High |

| Layer Height | 0.15-0.25mm | Medium |

| Shell Thickness | 1.2-2.0mm | High |

| Infill Density | 20-40% | Medium |

Fan speed recommendations:

First layer: 0%

Bridges: 15-20%

Overhangs: 10-15%

Standard layers: 5-10%

First Layer Considerations

Initial layer success dramatically influences overall print quality. Statistical analysis shows proper first layer setup increases success rates by 90%.

Critical measurements:

Z-offset: 0.1-0.15mm

Layer height: 0.2-0.3mm

Line width: 120-130%

Bed levelness: ±0.02mm

Troubleshooting Common Issues of 3D Printing with ABS

Print Quality Problems

Research identifies primary failure modes and solutions:

Common defects analysis:

| Issue | Frequency | Primary Cause | Success Rate After Fix |

| Warping | 45% | Temperature delta | 85% |

| Layer separation | 30% | Poor adhesion | 90% |

| Surface defects | 15% | Moisture | 95% |

| Dimensional inaccuracy | 10% | Calibration | 98% |

Material-Related Issues

Moisture impact metrics:

Absorption rate: 0.2-0.3% per day

Strength reduction: up to 40%

Surface quality degradation: visible after 2% moisture content

Print failure increase: 65% with wet filament

Recommended storage conditions:

Temperature: 20-25°C

Relative humidity: <30%

Air exposure: minimal

Container type: airtight with desiccant

Environmental Challenges

Environmental control significantly impacts print success:

Impact factors:

Temperature fluctuations (±5°C = 70% failure rate)

Draft exposure (>0.3 m/s = 85% failure rate)

Humidity variations (>50% RH = 60% quality reduction)

VOC accumulation (>100 ppm = health risk)

Post-Processing Techniques for ABS Printed Parts

Surface Finishing

Progressive Sanding Protocol forms the foundation of surface refinement. Start with 120-grit sandpaper for initial layer removal, gradually progressing through 240, 400, and 800 grits. This systematic approach ensures uniform surface development without compromising structural integrity.

Essential Tools and Materials required for professional results include:

| Tool Category | Specific Items | Purpose |

| Abrasives | Wet/dry sandpaper (120-2000 grit) | Surface leveling |

| Power Tools | Variable speed orbital sander | Large area processing |

| Hand Tools | Sanding blocks, files | Detail work |

| Consumables | Polishing compounds, microfiber cloths | Final finishing |

Advanced Polishing Methods enhance surface quality beyond basic sanding:

Mechanical buffing using compound wheels

Wet polishing with diamond pastes

Micro-mesh padding for ultra-smooth finish

Rotary tool techniques for detailed areas

Chemical Treatment

Acetone Smoothing Processes deliver professional-grade surface finish:

Basic Parameters:Temperature: 45-50°C

Exposure Duration: 15-30 minutes

Ventilation Period: 60+ minutes

Chamber Volume: 2L per 100cm³ part

Vapor Smoothing Safety Protocols demand strict adherence:

Proper ventilation systems

Chemical-resistant PPE usage

Temperature monitoring

Emergency response preparation

Controlled environment maintenance

Application Methodologies vary based on part complexity:

Direct vapor exposure for simple geometries

Controlled chamber treatment for intricate parts

Brush application for selective smoothing

Dipping technique for uniform treatment

Assembly and Finishing

Bonding Techniques selection criteria:

| Method | Strength | Application Time | Best Use Case |

| Solvent Welding | Very High | 5-10 min | Structural joints |

| Thermal Bonding | High | 15-20 min | Large surfaces |

| Adhesive Joining | Medium | 30-45 min | Complex assemblies |

Surface Preparation Sequence for optimal results:

Mechanical cleaning (120-grit abrasion)

Chemical degreasing

Surface activation treatment

Primer application

Paint preparation

Final Assembly Guidelines ensure professional outcomes:

Alignment verification using jigs

Sequential assembly planning

Stress point reinforcement

Quality control checkpoints

Functional testing procedures

Surface Treatment Options provide diverse finishing possibilities:

Primer application techniques

Paint compatibility considerations

Clear coat protection methods

Texture application procedures

Best Practices and Tips

Material Handling

Storage environment metrics:

Optimal conditions:Temperature: 20-22°C

Relative Humidity: 25-30%

Light Exposure: <50 lux

Air Exchange Rate: 0.5-1.0 ACH

Quality maintenance protocols:

Weekly moisture content testing

Quarterly material property verification

Continuous environment monitoring

Regular desiccant replacement

Print Optimization

Performance improvement data:

| Optimization Step | Quality Impact | Time Investment | ROI Rating |

| Temperature Calibration | +40% | 2 hours | High |

| Retraction Tuning | +25% | 1 hour | Medium |

| Speed Optimization | +20% | 3 hours | High |

| Flow Rate Adjustment | +15% | 30 minutes | Very High |

Test print sequence:

Temperature tower (45 minutes)

Retraction test (30 minutes)

Bridging test (20 minutes)

Overhang evaluation (25 minutes)

Safety Considerations

Workspace safety requirements:

Essential safety metrics:

Air exchange rate: 6-8 ACH

VOC threshold: <50 ppm

Particulate filtration: 0.3μm at 99.97%

Emergency response time: <30 seconds

Conclusion

The journey through ABS 3D printing reveals both its challenges and remarkable potential. While requiring careful attention to temperature control, ventilation, and print settings, the rewards of mastering ABS printing are substantial. Its unmatched combination of durability, heat resistance, and post-processing flexibility continues driving innovation across industries.

As additive manufacturing technology evolves, ABS remains at the forefront, adapting to new applications and challenges. The future of ABS printing looks promising, with ongoing developments in material science and printing technology promising even greater possibilities for this versatile filament.

Ready to elevate your 3D printing game with ABS? TEAM MFG brings you professional-grade ABS printing solutions backed by decades of manufacturing expertise. From prototype to production, we'll help you unlock ABS's full potential. Contact our experts today or visit Team Mfgfor a free consultation.

Reference Sources

3D printing

ABS Plastic

3D Printing Materials

Frequently Asked Questions: 3D Printing with ABS

Q1: Why does my ABS print warp?

A: Warping occurs from uneven cooling. Use a heated bed (100-110°C), enclosed chamber, and proper adhesion solutions.

Q2: Is ABS toxic?

A: Yes, ABS releases fumes during printing. Always use ventilation and an enclosure. Avoid prolonged exposure.

Q3: What's the ideal printing temperature?

A: Nozzle: 230-250°C

Bed: 100-110°C

Chamber: 45-50°C

Q4: Why do I need an enclosure?

A: Enclosures maintain temperature, prevent warping, contain fumes, and improve layer adhesion.

Q5: How should I store ABS?

A: In airtight containers with desiccant at 20-25°C, below 30% humidity.

Q6: Best way to smooth ABS?

A: Either acetone vapor smoothing (quick, glossy) or progressive sanding (more control).

Q7: Why are prints brittle?

A: Usually from wet filament, low temperature, or poor layer adhesion. Dry filament and increase temperature to fix.