What is Pressure Die Casting Service?

Pressure die casting Service is a quick, reliable and cost-effective manufacturing process for production of high volume, metal components that are net-shaped have tight tolerances. Basically, the pressure die casting process consists of injecting under high pressure a molten metal alloy into a steel mold (or tool). This gets solidified rapidly (from milliseconds to a few seconds) to form a net shaped component. It is then automatically extracted.

What can we supply about Pressure Die Casting Service for you?

TEAM MFG provides total solutions in the field of pressure die-casting and machining. With more than a decade of experience, we challenge the processes of tooling, die-casting and machining with our knowledge, passion and hard work.

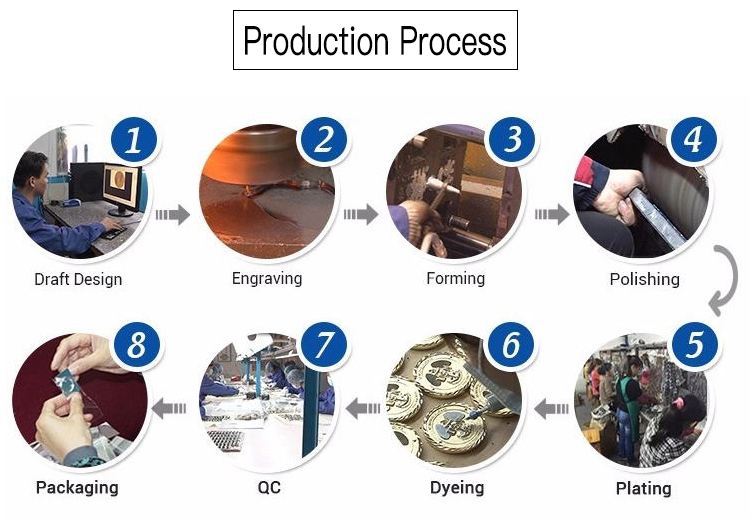

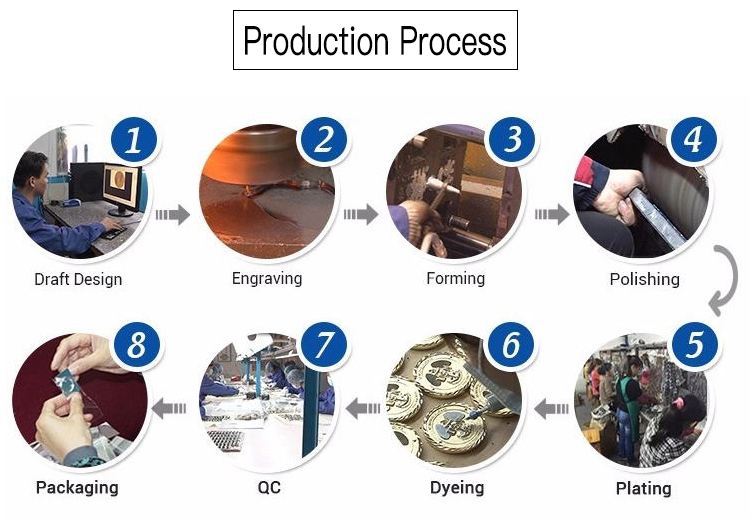

We have consolidated the entire setup under one roof comprising of die-casting, trimming, machining, surface finishing, and quality inspection. This helps us meet our customer requirements comfortably and helps them expedite the decision-making process.

Depending upon the pressure used, there are two types of pressure die casting namely High Pressure Die Casting and Low Pressure Die Casting.

While high pressure die casting has wider application encompassing nearly 50% of all light alloy casting production.

Currently low pressure die casting accounts for about 20% of the total production but its use is increasing.

High Pressure Die Casting

High pressure castings are must for castings requiring tight tolerance and detailed geometry. As the extra pressure is able to push the metal into more detailed features in the mold.

Low Pressure Die Casting

Low pressure die casting is commonly used for larger and non-critical parts.

Pressure Die casting is a metal of plastic casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminum, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production.

Manufacture of parts using pressure die casting is technically challenging, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process.

Pressure Die castings are characterized by a very good surface finish (by casting standards) and dimensional consistency.