CNC milling has revolutionized modern manufacturing, but have you ever wondered which milling method is better? Climb Milling or Conventional Milling? Both techniques play crucial roles in producing high-quality parts, but each method has unique benefits and challenges.

In this article, we’ll explore how CNC milling works, and why understanding the difference between Climb Milling and Conventional Milling is essential for machinists. You’ll learn how to choose the right method based on material, machine, and manufacturing goals to improve efficiency and product quality.

What is Climb Milling?

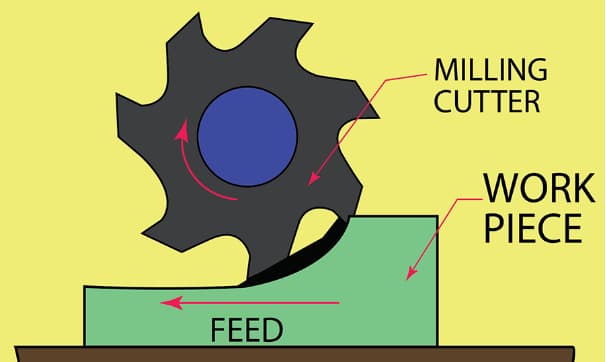

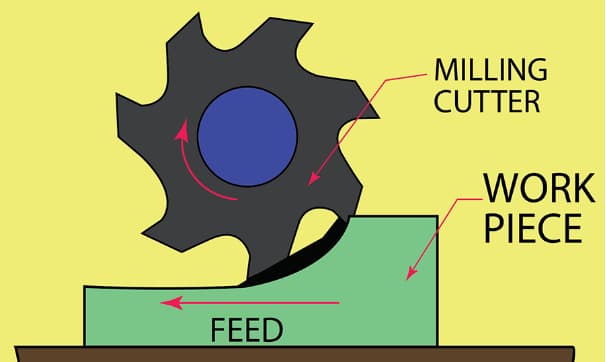

Climb Milling, also known as Down Milling, refers to the cutting process where the cutting tool rotates in the same direction as the feed motion. It allows the cutter's teeth to engage the workpiece from the top, reducing the chance of recutting chips. This method generates cleaner cuts and is ideal for parts requiring a smoother surface finish.

How Climb Milling Works

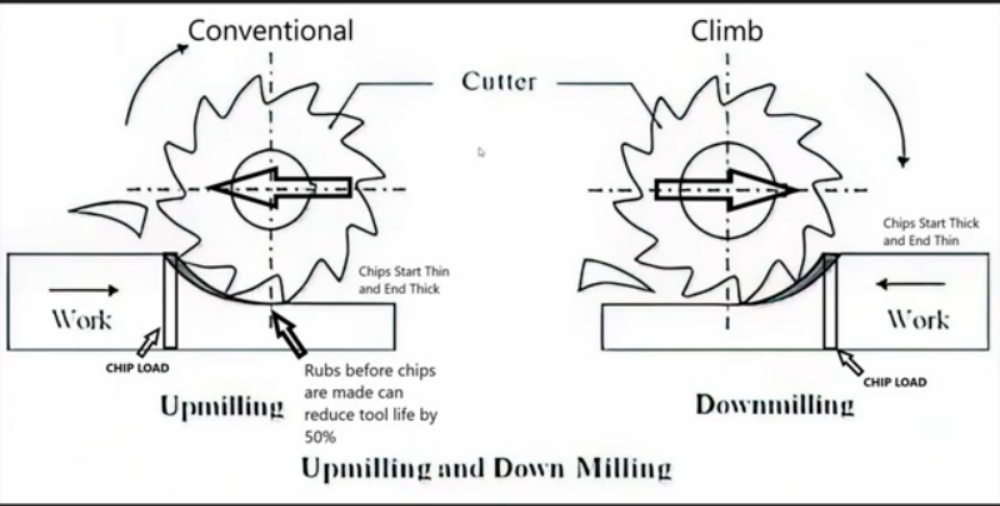

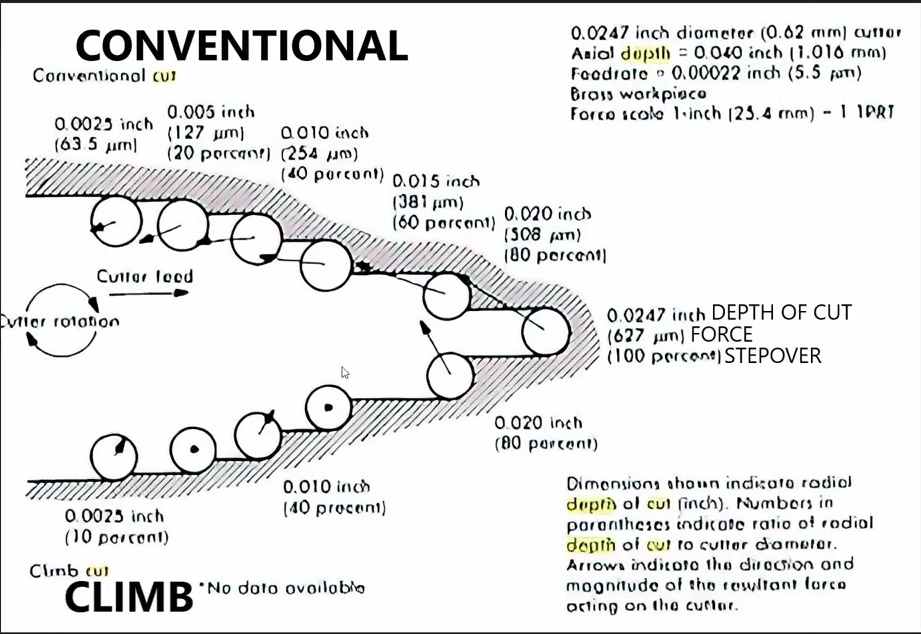

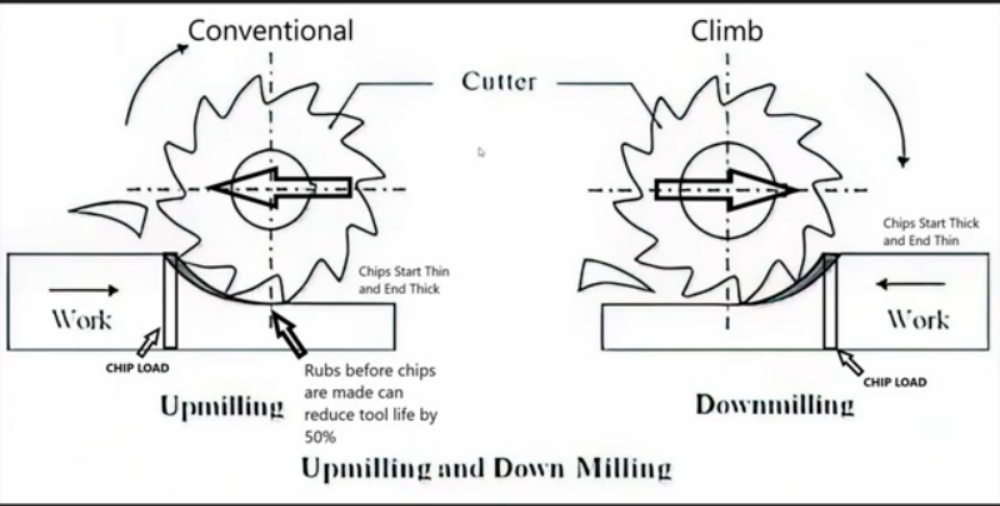

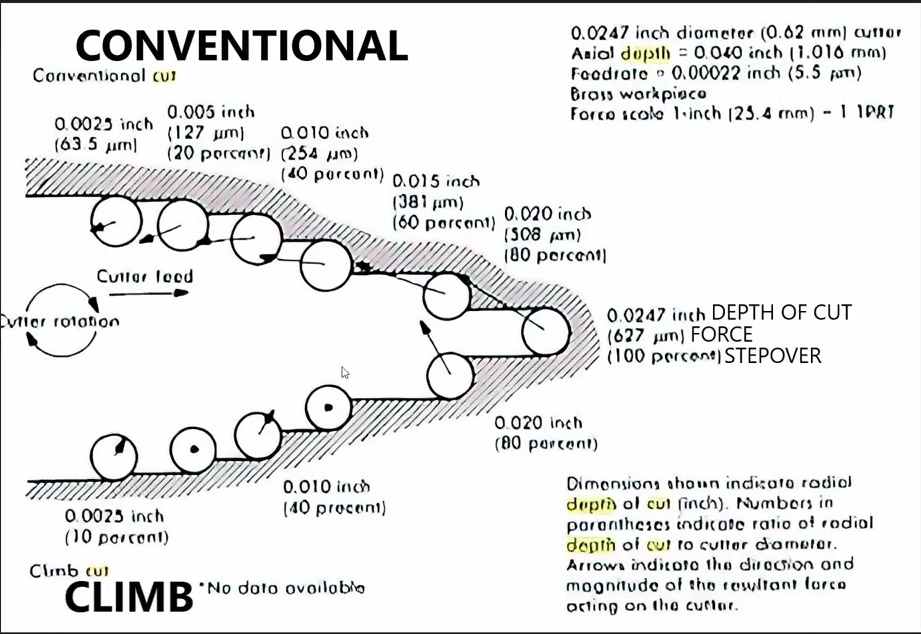

In Climb Milling, chip formation starts thick and becomes thinner as the cutter moves through the material. This chip formation pattern reduces the cutting forces, resulting in lower heat generation and better efficiency. The cutting motion directs chips behind the tool, eliminating the need for re-cutting, which preserves tool sharpness and enhances the surface finish.

Chip Formation: Begins thick and gradually thins out, reducing stress on the tool.

Tool Path and Motion: The cutter rotates in the same direction as the feed, pushing the workpiece downward, improving stability.

Key Characteristics of Climb Milling

Climb Milling offers several advantages for precision work:

Reduced Tool Deflection: The tool experiences less bending during the cut, improving accuracy.

Better Surface Finish: Fewer tool marks and smoother surfaces result from controlled chip formation.

Lower Cutting Load: The load placed on the cutting tool is lower, reducing heat and wear.

Advantages of Climb Milling

Improved Surface Finish: Leaves behind a cleaner surface compared to conventional milling.

Reduced Tool Wear: The tool experiences less friction, extending its lifespan and reducing wear.

Lower Heat Generation: Generates less heat, improving cutting efficiency and reducing tool overheating.

Simpler Workholding: The downward force helps secure the workpiece, simplifying clamping requirements.

Disadvantages of Climb Milling

However, Climb Milling also has drawbacks, especially for certain materials and machine setups:

Unsuitable for Hard Surfaces: Not ideal for materials like hardened steel, which can damage the tool.

Vibration Issues: Backlash in the feed mechanism may cause vibrations during cutting.

Machine Requirements: It requires machines with backlash elimination or compensation to prevent tool breakage.

What is Conventional Milling?

Detailed Explanation of Conventional Milling (Up Milling)

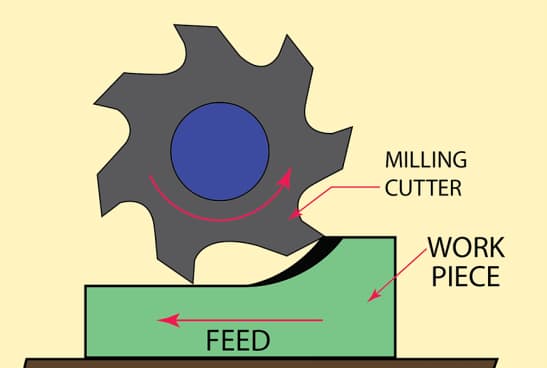

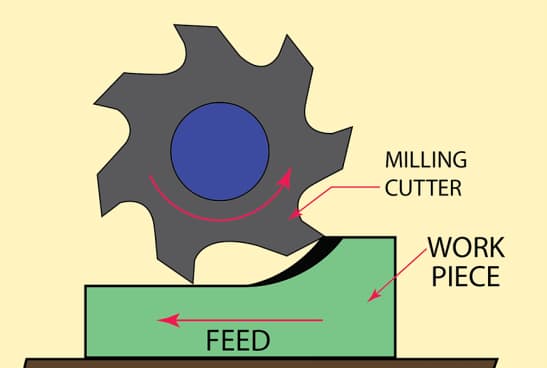

Conventional milling, also referred to as up milling, is a traditional machining technique where the cutting tool rotates against the feed direction of the workpiece. This method has been widely used in manufacturing for decades due to its unique characteristics and advantages in specific applications.

Conventional Milling Direction and Its Effect on the Cutting Process

In conventional milling:

The cutter rotates opposite to the workpiece feed direction

Cutting teeth engage the material from the bottom, moving upward

Chip thickness starts at zero and increases to maximum at the end of the cut

This upward motion creates distinct effects on the machining process, influencing chip formation, tool wear, and surface finish.

Characteristics and Properties of Conventional Milling

Chip Formation: Thin-to-thick chip pattern

Cutting Forces: Upward forces tend to lift the workpiece

Tool Engagement: Gradual increase in cutting load as the tooth progresses

Heat Generation: Higher heat concentration in the cutting zone

Advantages of Conventional Milling

Enhanced Stability: Gradual tool engagement provides better control, especially for harder materials

Backlash Elimination: Upward forces naturally compensate for machine backlash

Hard Surface Compatibility: Ideal for machining materials hard surfaces or abrasive substances

Chatter Reduction: Less prone to vibration in certain setups

Disadvantages of Conventional Milling

Inferior Surface Finish: Upward chip evacuation can lead to re-cutting and surface marring

Accelerated Tool Wear: Increased friction and heat generation reduce tool lifespan

Thermal Stress: Higher cutting loads and heat can cause workpiece distortion

Complex Workholding: Stronger clamping required to counteract lifting forces

Climb Milling vs Conventional Milling: Key Differences

Chip Formation and Direction

| Aspect | Climb Milling | Conventional Milling |

| Chip Thickness | Thick to thin | Thin to thick |

| Heat Distribution | Efficient heat transfer to chips | Heat concentration in cutting zone |

| Tool Stress | Lower initial impact | Gradual increase in cutting load |

The chip formation pattern significantly influences heat generation and tool wear. Climb milling's thick-to-thin chips facilitate better heat dissipation, reducing thermal stress on the tool and workpiece.

Tool Deflection and Cutting Accuracy

Tool deflection direction impacts machining precision. Parallel deflection in conventional milling often provides better control, especially when working hard materials or in roughing operations.

Climb milling typically produces smoother surface finishes due to:

Efficient chip evacuation

Reduced likelihood of chip recutting

Downward cutting forces that minimize workpiece lifting

Conventional milling may result in rougher surfaces caused by upward chip flow and potential recutting of chips.

Tool Life and Wear

Climb milling extends tool life through:

Lower initial impact stress on cutting edges

Reduced friction and heat generation

Efficient chip evacuation, minimizing abrasion

Conventional milling tends to cause accelerated tool wear due to:

Gradual increase in cutting load

Higher friction as the tool rubs against the workpiece

Increased heat concentration in the cutting zone

Suitable Workpiece Materials

| Material Type | Preferred Milling Method |

| Soft metals (e.g., aluminum) | Climb Milling |

| Hard alloys (e.g., titanium) | Conventional Milling |

| Plastics and composites | Climb Milling |

| Work-hardening materials | Climb Milling |

| Abrasive materials | Conventional Milling |

Factors to Consider When Choosing Between Climb and Conventional Milling

Machine Capabilities

Backlash Elimination: Essential for climb milling to prevent vibration and potential damage.

Rigidity: Higher machine rigidity allows for more effective climb milling, especially in high-speed applications.

Control System: Advanced CNC systems can compensate for backlash, enabling safer climb milling operations.

Workpiece Material Properties

| Material Characteristic | Preferred Milling Method |

| Soft and ductile | Climb Milling |

| Hard and brittle | Conventional Milling |

| Work-hardening | Climb Milling |

| Abrasive | Conventional Milling |

Consider material-specific challenges such as chip formation, heat generation, and tool wear when selecting the milling technique.

Cutting Tool Geometry and Coating

Rake Angle: Positive rake angles often perform better in climb milling, while negative rake angles suit conventional milling for harder materials.

Flute Design: Tools designed for climb milling typically have more efficient chip evacuation channels.

Coatings: TiAlN or TiCN coatings can enhance tool performance in both milling methods, improving wear resistance and heat dissipation.

Desired Surface Finish and Dimensional Accuracy

Climb milling generally produces:

Smoother surface finishes

Better dimensional accuracy in softer materials

Reduced risk of burr formation

Conventional milling may be preferred for:

Roughing operations

Machining hard materials where surface finish is less critical

Applications requiring strict control over cutting depth

Machining Parameters

| Parameter | Climb Milling | Conventional Milling |

| Cutting Speed | Higher speeds possible | Lower speeds may be necessary |

| Feed Rate | Can handle higher feed rates | May require reduced feed rates |

| Depth of Cut | Shallower cuts recommended | Can handle deeper cuts |

Optimize these parameters based on the chosen milling method, workpiece material, and desired outcome. Proper adjustment ensures optimal chip formation, tool life, and surface quality.

Applications of Climb Milling and Conventional Milling

Aerospace Industry

The aerospace sector heavily relies on advanced milling techniques to manufacture critical components:

Aircraft Structures

Climb milling: Ideal for aluminum alloy parts, ensuring smooth surface finishes and tight tolerances.

Conventional milling: Preferred for hardened steel components, providing stability during machining.

Engine Components

Turbine blades: Climb milling excels in producing complex airfoil shapes, minimizing tool wear when working titanium alloys.

Combustion chambers: Conventional milling offers better control for intricate internal features and heat-resistant superalloys.

Landing Gear Parts

Struts: Climb milling delivers superior surface finish, crucial for fatigue resistance.

Pivot pins: Conventional milling ensures dimensional accuracy when machining hardened steels.

Automotive Industry

Milling techniques play a vital role in automotive manufacturing:

| Component | Climb Milling | Conventional Milling |

| Engine Blocks | Finish passes for cylinder bores | Rough machining of cast iron blocks |

| Transmission Cases | Final surface finishing | Initial material removal |

| Cylinder Heads | Valve seat machining | Port roughing operations |

Medical Device Manufacturing

Precision milling critical for producing medical devices:

Orthopedic Implants

Surgical Instruments

Dental Components

Technological Advancements and Their Impact on Climb and Conventional Milling

High-Speed Machining (HSM)

HSM revolutionizes both climb and conventional milling techniques:

HSM Applications Across Industries

Aerospace:

Turbine blade manufacturing with spindle speeds up to 40,000 RPM

Structural component production reducing part count by 42%

Automotive:

Medical:

Advanced Cutting Tool Materials

Modern tool materials significantly impact milling performance:

| Material | Hardness (HV) | Best For |

| Carbide | 1,300 - 1,800 | Versatile, high-speed applications |

| Ceramic | 2,100 - 2,400 | Heat-resistant alloys, hardened steels |

| HSS | 800 - 900 | Softer materials, cost-effective option |

| Diamond-coated | >10,000 | Abrasive materials, ultra-precision work |

Key Benefits:

Carbide inserts: Extended tool life, improved productivity in both milling techniques

Ceramic inserts: Excellent for high-temperature machining in aerospace applications

HSS tools: Cost-effective for general-purpose milling operations

Diamond-coated tools: Unparalleled wear resistance for non-ferrous materials

Computer-Aided Manufacturing (CAM) Software

CAM software enhances milling strategies through advanced features:

Adaptive Clearing: Optimizes tool paths based on remaining material, benefiting both milling methods.

High-Speed Machining (HSM) Algorithms: Reduces cycle times and improves surface finishes in climb milling.

Trochoidal Milling: Utilizes circular tool paths to minimize heat generation in conventional milling.

Rest Machining: Efficiently removes material left by larger tools, complementing both techniques.

Popular CAM Software Packages:

Autodesk Fusion 360

Mastercam

SolidCAM

HSMWorks

CAMWorks

These software solutions offer comprehensive simulation capabilities, allowing machinists to optimize milling strategies before actual production. They seamlessly integrate climb and conventional milling techniques to achieve optimal results across various manufacturing scenarios.

Challenges and Considerations in Climb and Conventional Milling

Tool Deflection and Chatter

Causes and Effects

| Issue | Causes | Effects |

| Tool Deflection | Material hardness, cutting depth, tool geometry | Dimensional inaccuracies, poor surface finish |

| Chatter | Mismatched tool and machine frequencies, excessive cutting forces | Vibrations, surface imperfections, reduced tool life |

Mitigation Strategies

Use shorter, rigid tools to minimize deflection

Optimize spindle speeds to avoid resonant frequencies

Implement advanced workholding techniques for improved stability

Employ high-pressure coolant systems to reduce cutting forces

Chip Formation and Evacuation

Comparative Analysis

| Aspect | Climb Milling | Conventional Milling |

| Chip Formation | Thick-to-thin pattern | Thin-to-thick pattern |

| Evacuation Direction | Away from cutting zone | Towards cutting zone |

| Heat Distribution | Efficient heat transfer to chips | Heat concentration in cutting area |

Optimization Methods

Balance cutting parameters (speed, feed, depth) for optimal chip formation

Select tools with polished flutes and higher helix angles for improved evacuation

Implement air blasts or high-pressure coolant for efficient chip removal

Adjust tool coatings to prevent chip adhesion and improve evacuation

Influence of Workpiece Material and Geometry

Material Impact on Milling Technique Selection

Soft, ductile materials (e.g., aluminum): Climb milling preferred for better surface finish

Hard, brittle materials (e.g., hardened steel): Conventional milling offers more stability

Work-hardening materials: Climb milling reduces the risk of strain hardening

Abrasive materials: Conventional milling provides better tool life and control

Geometry Considerations

External cuts: Climb milling excels in peripheral milling operations

Internal features: Conventional milling offers better control for slots and pockets

Thin-walled components: Climb milling reduces the risk of deformation

Complex contours: Combination of both techniques may be necessary for optimal results

Best Practices and Tips for Climb Milling and Conventional Milling

Proper Selection of Cutting Parameters

Optimize milling performance by fine-tuning these critical parameters:

Cutting Speed: Adjust based on material properties and tool capabilities

Feed Rate: Balance with cutting speed for optimal chip formation

Depth of Cut: Control to manage cutting forces and heat generation

| Parameter | Climb Milling | Conventional Milling |

| Cutting Speed | Higher speeds possible | Moderate speeds recommended |

| Feed Rate | Can handle higher feeds | Lower feeds for stability |

| Depth of Cut | Shallower cuts preferred | Can manage deeper cuts |

Optimizing Tool Geometry and Coating

Select appropriate tool characteristics for specific applications:

Rake Angle: Positive for climb milling, negative for conventional in harder materials

Helix Angle: Higher angles improve chip evacuation in climb milling

Flute Design: Open flutes for better chip flow in conventional milling

Coatings: TiAlN for high-temperature resistance, TiCN for abrasive materials

Controlling Chip Formation and Evacuation

Enhance chip management through these strategies:

Implement high-pressure coolant systems for efficient chip removal

Use air blasts to prevent chip recutting in conventional milling

Select tools with polished flutes to reduce chip adhesion

Adjust cutting parameters to achieve optimal chip thickness

Minimizing Tool Deflection and Chatter

Reduce vibration and maintain accuracy:

Employ rigid toolholding systems to minimize deflection

Optimize spindle speeds to avoid resonant frequencies

Use shorter tool overhangs when possible

Implement vibration damping tools for challenging materials

Ensuring Proper Workholding and Machine Rigidity

Maximize stability and precision:

Utilize robust fixturing systems appropriate for the milling technique

Implement multiple clamping points for large workpieces

Consider vacuum clamping for thin materials in climb milling

Regularly maintain and calibrate machine tools to ensure optimal rigidity

Conclusion

In summary, Climb Milling and Conventional Milling differ in chip formation, tool deflection, and surface finish. Climb Milling is ideal for softer materials and smoother finishes, while Conventional Milling suits harder materials and better control.

Use Climb Milling for softer materials like aluminum. Choose Conventional Milling when machining harder surfaces such as steel or cast iron. Machine type and the need for backlash compensation also affect the choice.

For optimal efficiency and extended tool life, match the milling method to the material and machining requirements. Proper technique selection reduces tool wear and improves performance.