Ever wondered how plastic parts stay securely fastened without screws or glue? Riveting offers a reliable solution. In this guide, we'll explore the essentials of plastic riveting, its significance in different industries, and how to choose the right method. You'll learn the ins and outs of riveting plastic parts for strong, durable connections.

What is Plastic Riveting?

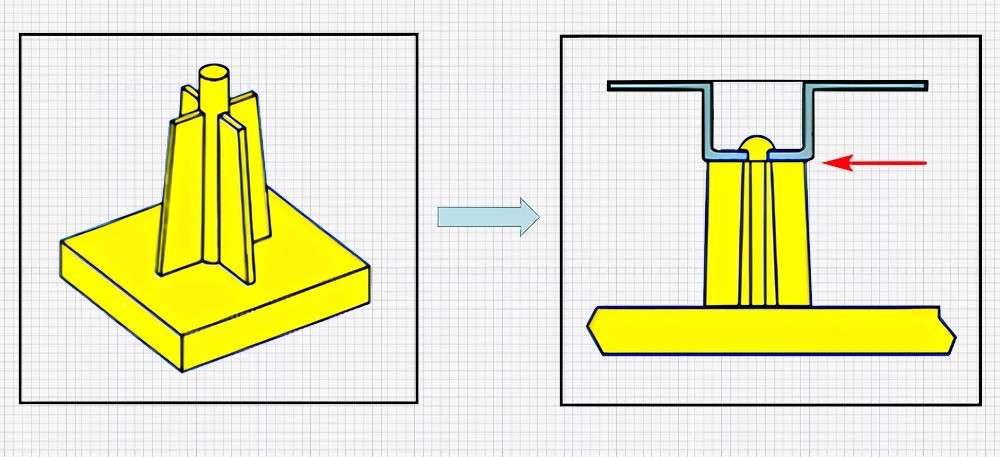

Plastic riveting is a mechanical fastening method. It involves using axial force to deform the shank of a rivet inside a hole. This forms a head, connecting multiple parts.

Compared to metal riveting, plastic riveting has some key differences. It doesn't require additional rivets or posts. Instead, it uses plastic structures like columns or ribs. They're part of the plastic body.

Advantages and Disadvantages of Plastic Riveting

Plastic riveting has several advantages and disadvantages. Let's take a closer look.

Common Advantages:

Simple part structure, reducing mold costs

Easy assembly, no extra materials or fasteners needed

High reliability

Can rivet multiple points simultaneously, improving efficiency

Joins plastic, metal, and non-metal parts, even in tight spaces

Withstands long-term vibration and extreme conditions

Simple, energy-saving, fast process

Easy visual quality inspection

Common Disadvantages:

Requires additional riveting equipment and tooling

Not suitable for high-strength or long-term loads

Permanent connection, not detachable or repairable

Difficult to repair if it fails

May need redundancy in design phase

| Advantage | Disadvantage |

| Simple structure, low mold costs | Needs extra equipment and tooling |

| Easy assembly, high reliability | Not for high-strength or long-term loads |

| Joins various materials efficiently | Permanent, not detachable or repairable |

| Withstands vibration and extreme conditions | Hard to repair, may need redundancy |

| Simple, fast, energy-saving process | - |

| Easy visual quality checks | - |

Types of Plastic Riveting Processes

There are three main types of plastic riveting processes. They are hot melt riveting, hot air riveting, and ultrasonic riveting.

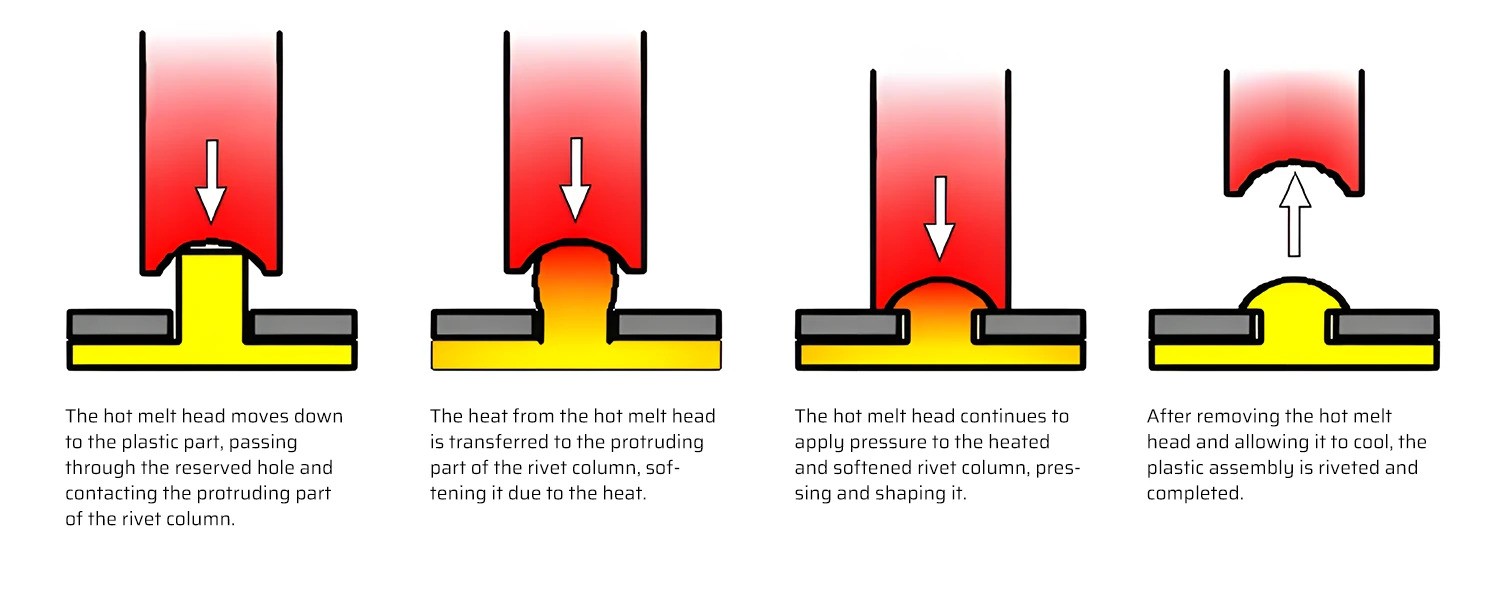

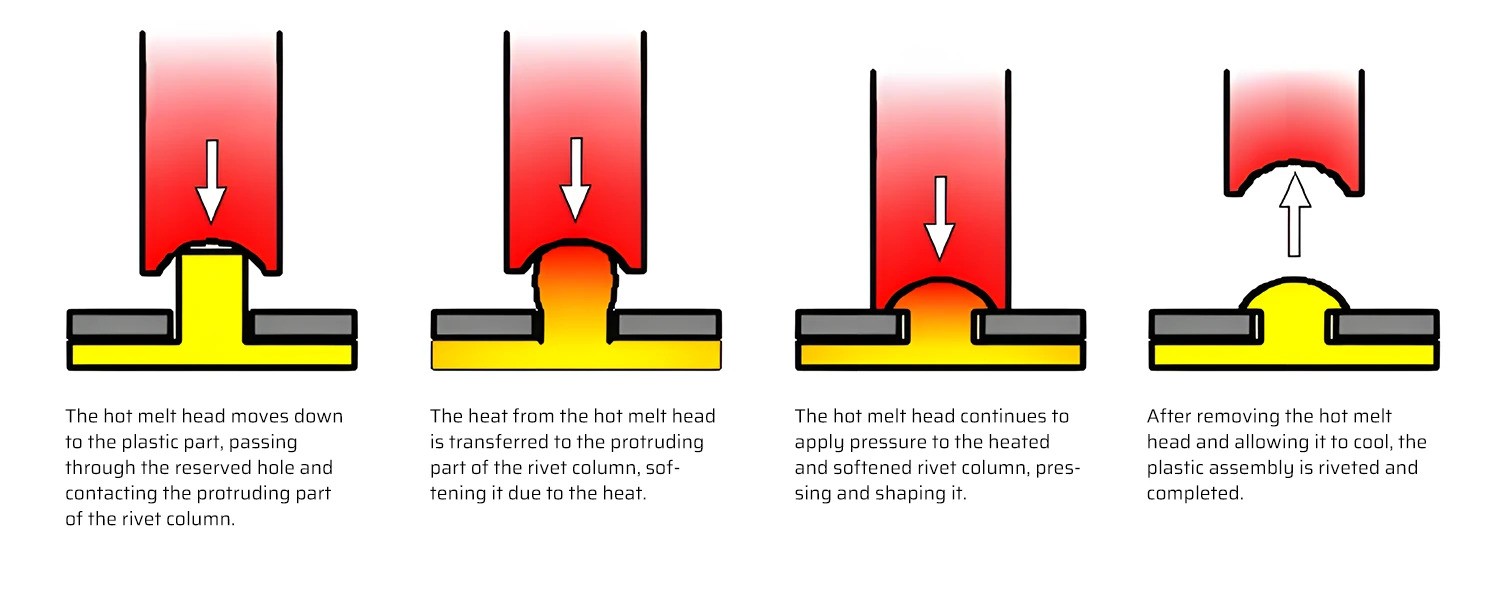

Hot Melt Riveting

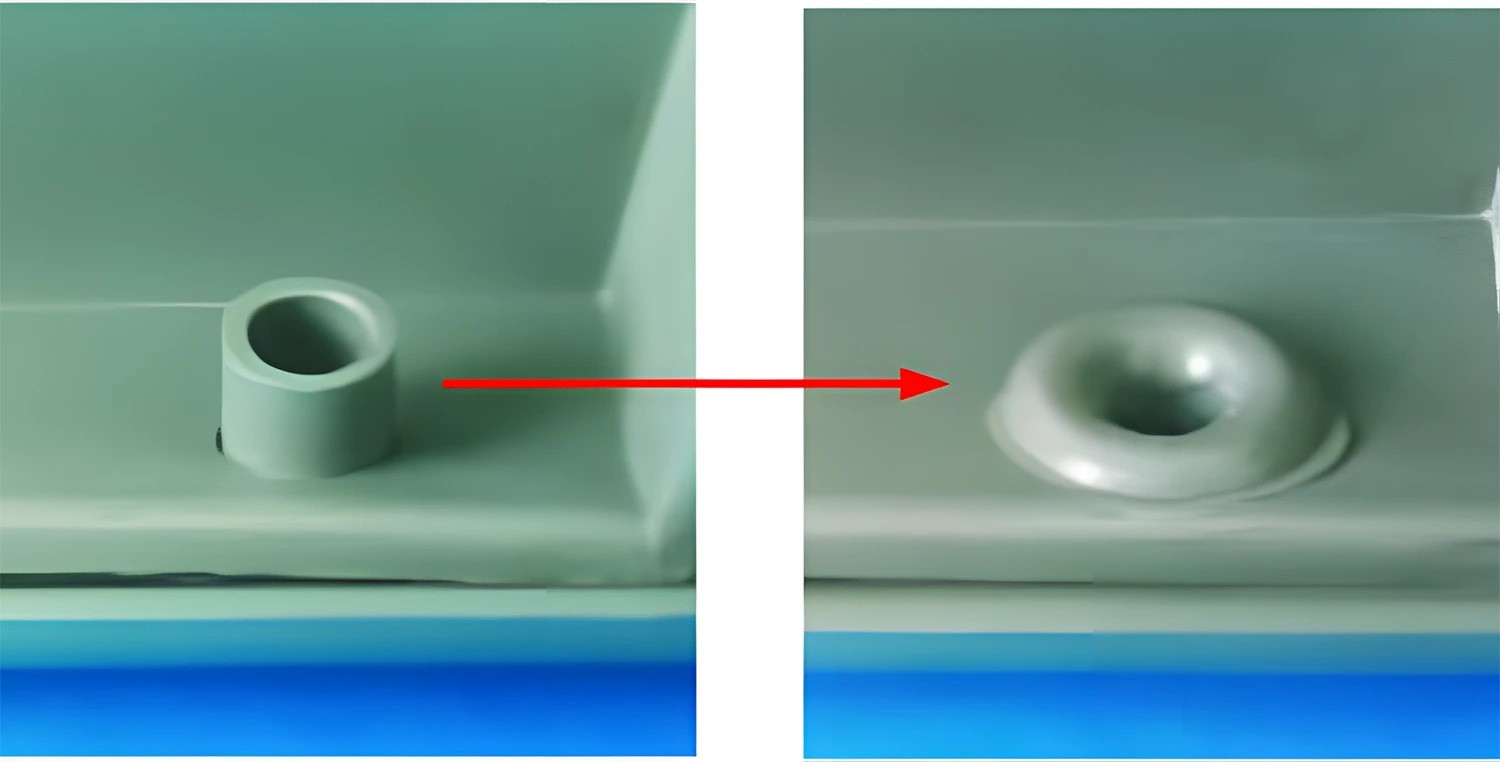

Hot melt riveting is a contact-type process. It involves a heating tube inside the riveting head. This heats the metal riveting head, which then melts and shapes the plastic rivet.

Advantages:

Disadvantages:

Insufficient cooling can cause plastic to stick to head

Not suitable for larger rivet columns

High residual stress and lower pull-out strength

Not recommended for products with high positioning/fixation requirements

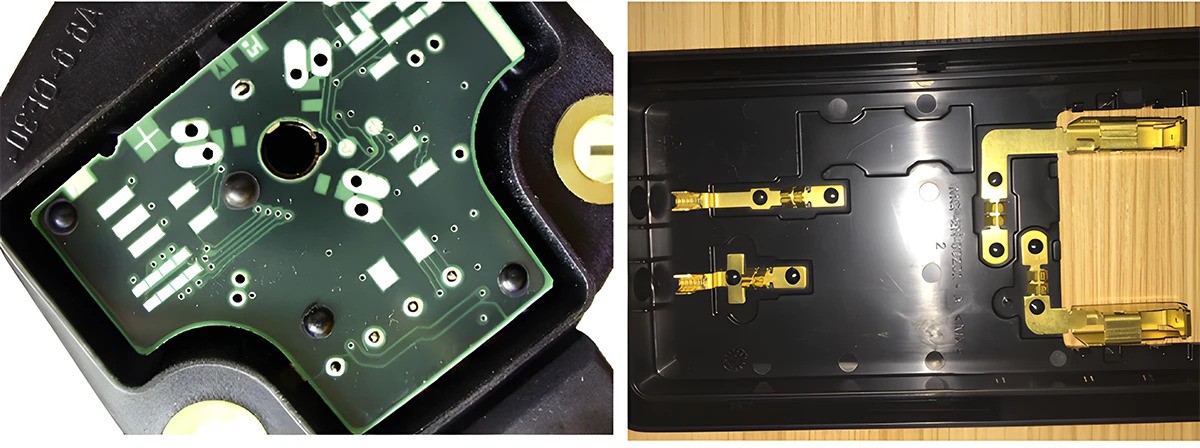

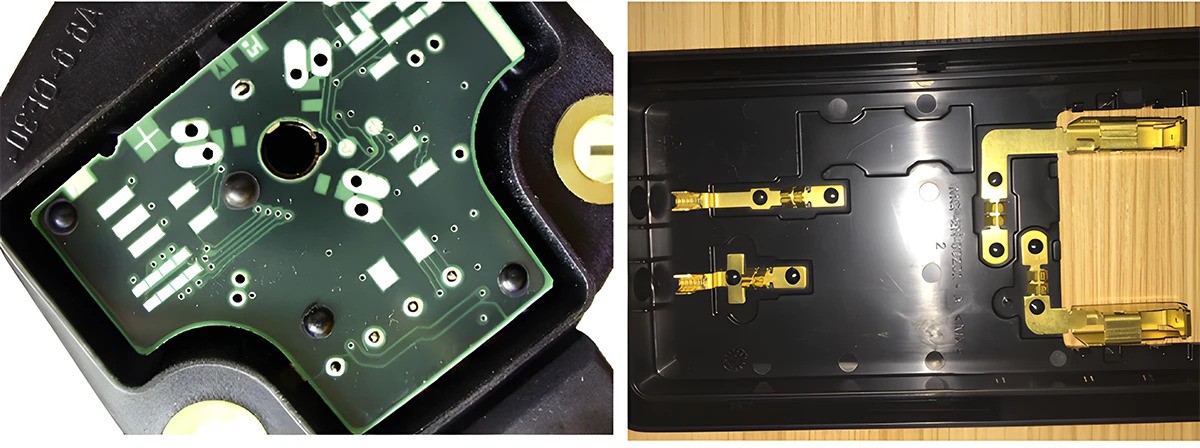

Hot melt riveting is commonly used for PCB boards and plastic decorative parts.

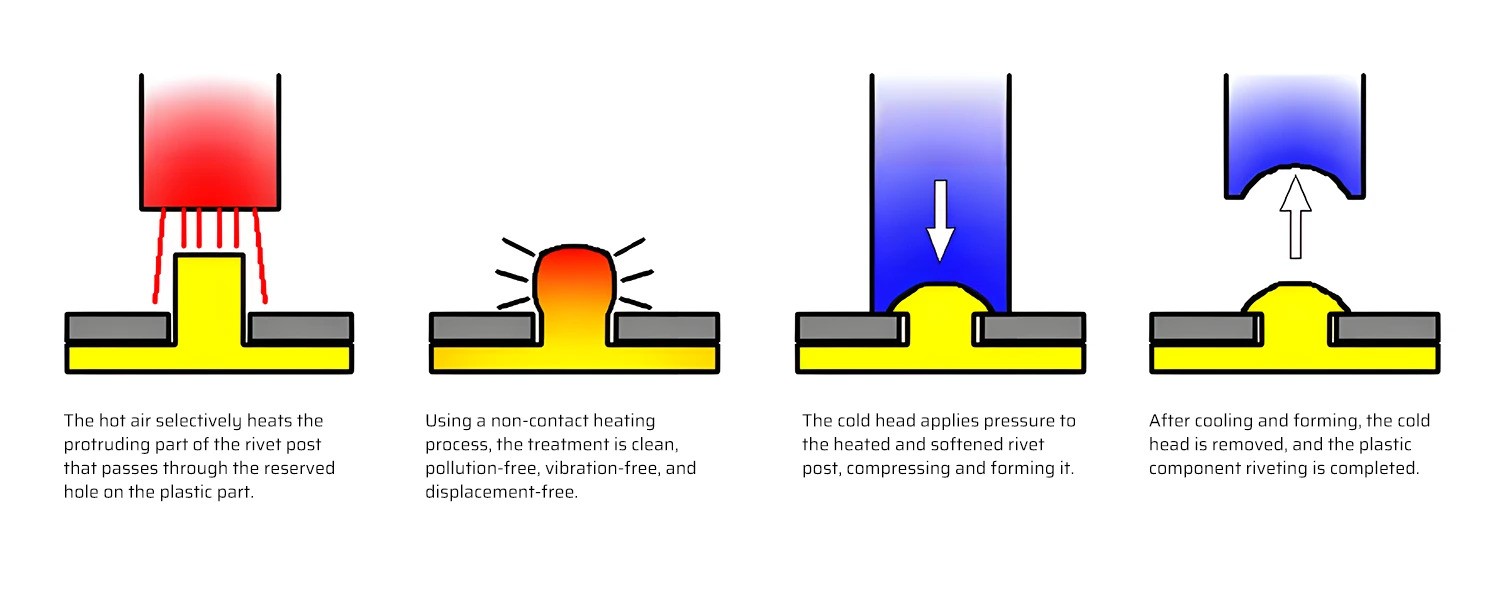

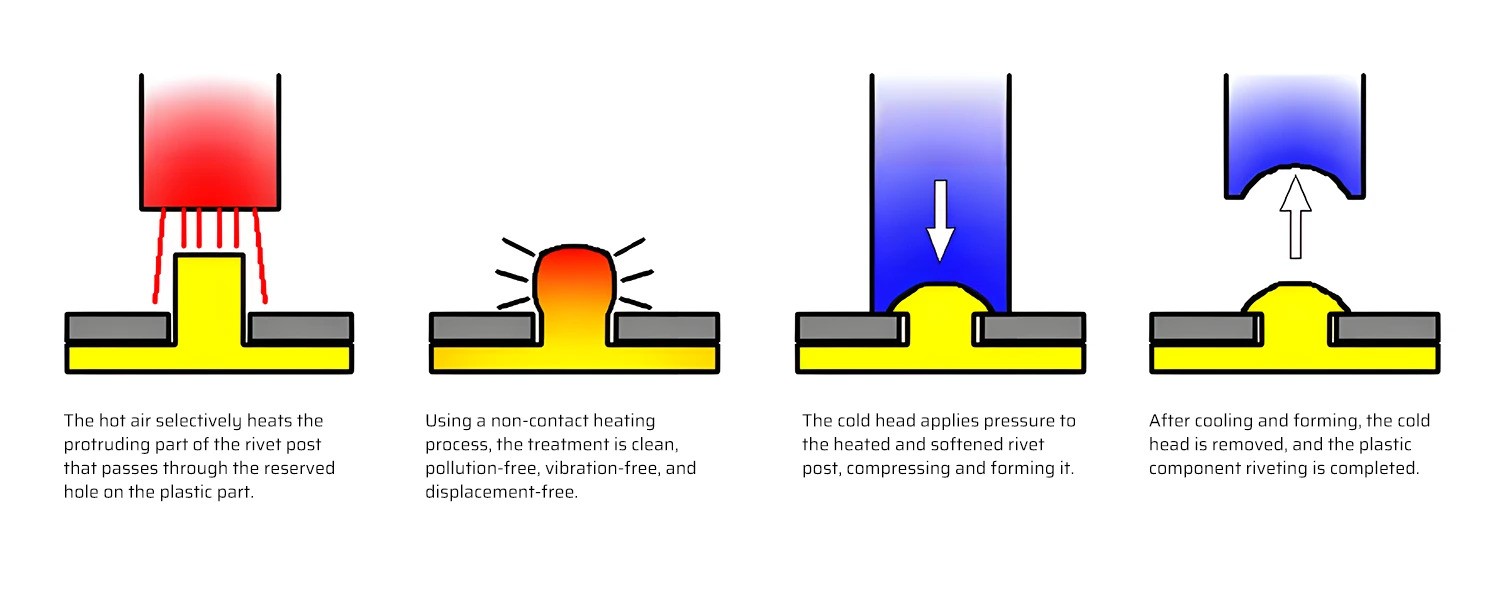

Hot Air Riveting (Hot Air Cold Riveting)

Hot air riveting is a non-contact process. It uses hot air to heat and soften the plastic rivet column. Then, a cold riveting head presses and shapes it.

The process has two stages:

Heating: Hot air uniformly heats the rivet column until it's malleable.

Cooling: The cold riveting head presses the softened column, forming a firm head.

Advantages:

Uniform heating reduces internal stress

Cold riveting head quickly fills gaps, achieving a good fixing effect

Disadvantages:

Hot air riveting is suitable for most thermoplastic materials and glass fiber reinforced plastics.

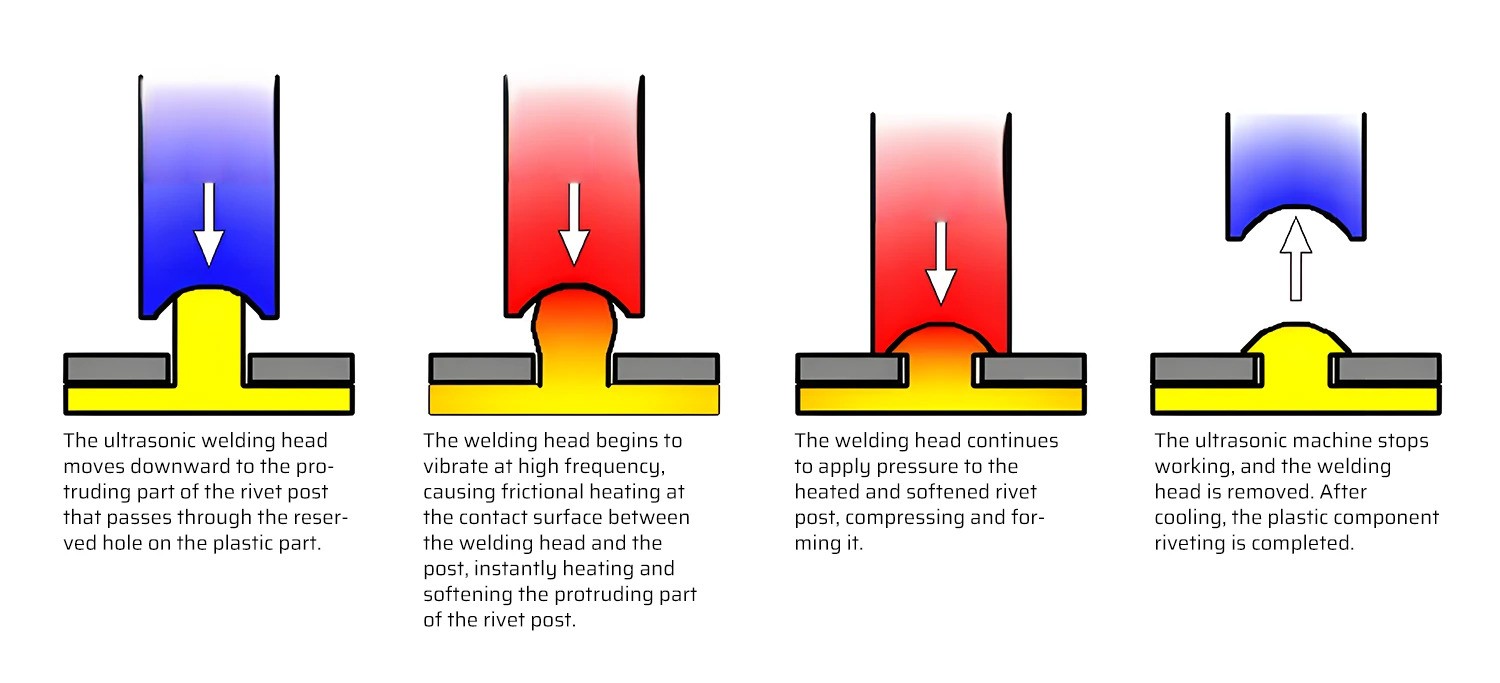

Ultrasonic Riveting

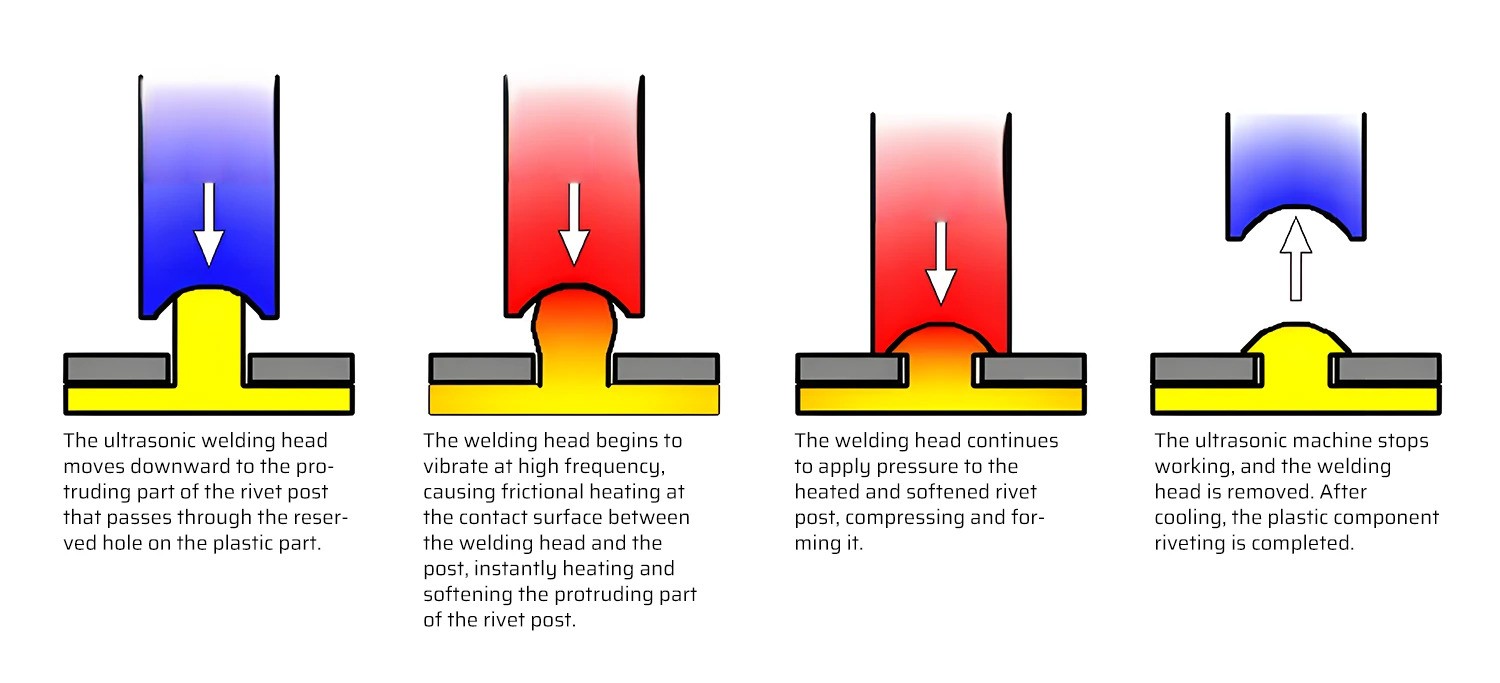

Ultrasonic riveting is another contact-type process. It uses high-frequency vibrations to generate heat and melt the plastic rivet column.

Advantages:

Disadvantages:

Uneven heating can cause loose or degraded columns

Limited distribution distance if using a single welding head

Vibrations can damage components to a certain extent

Ultrasonic riveting is not suitable for glass fiber materials or those with high melting points.

Here's a comparison table of the three processes:

| Process | Heating Method | Riveting Strength | Fixing Effect | Speed | Equipment Flexibility |

| Hot Melt | Contact (metal head) | Unreliable, sensitive to vibration | Defective due to incomplete softening | 6-60s | Integrated, complex changeover |

| Hot Air | Non-contact (hot air) | High, not sensitive to vibration | Excellent, completely fills gaps | 8-12s | Adjustable heating and riveting |

| Ultrasonic | Contact (vibration) | Unreliable | Defective due to incomplete softening | <5s | Limited control with integrated head |

Common Rivet Head Types for Plastic Parts

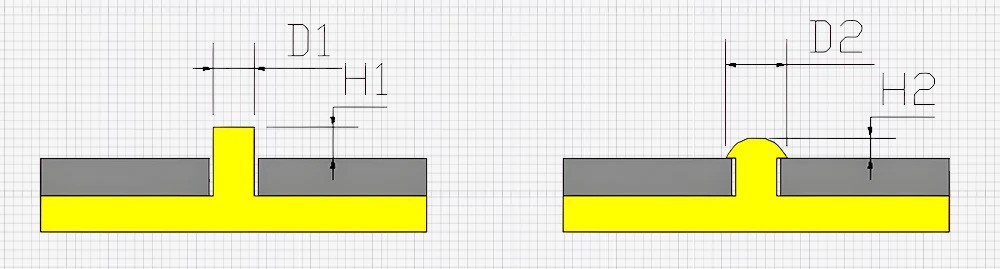

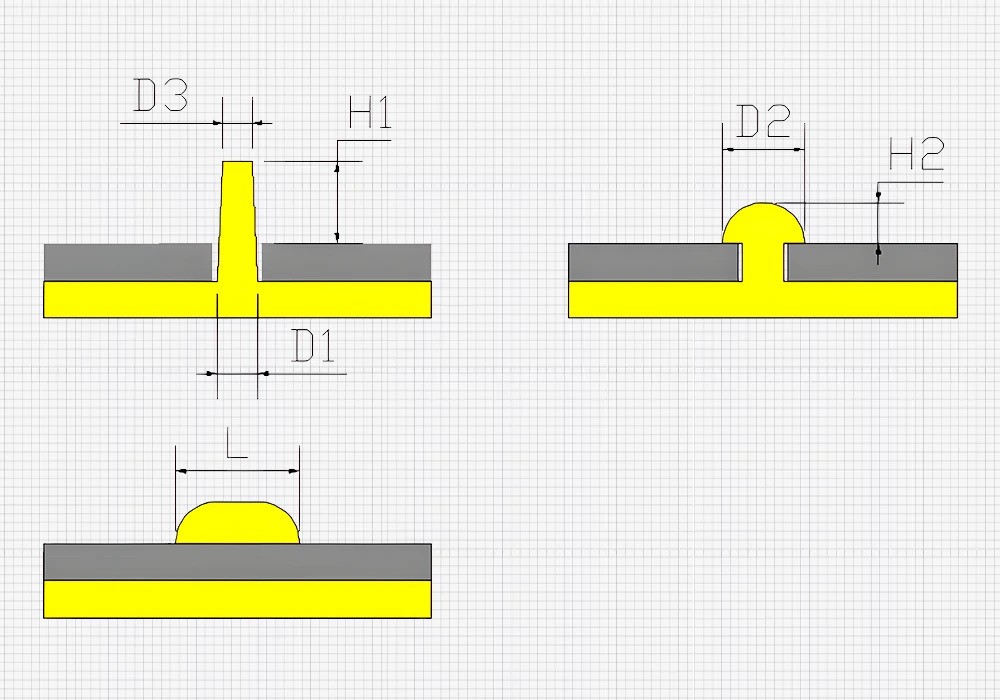

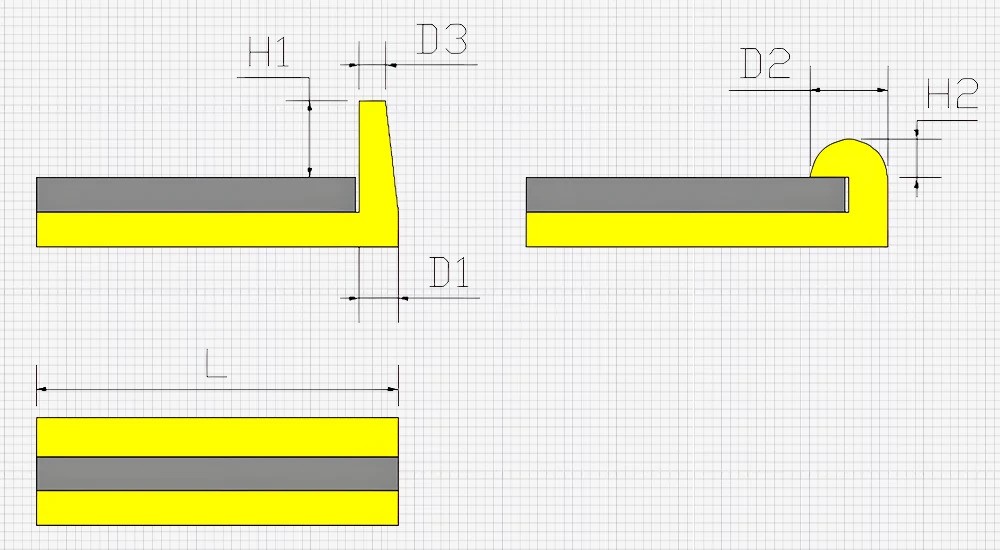

When it comes to plastic riveting, the geometry and dimensions of rivet heads are crucial. Let's take a look at some common types.

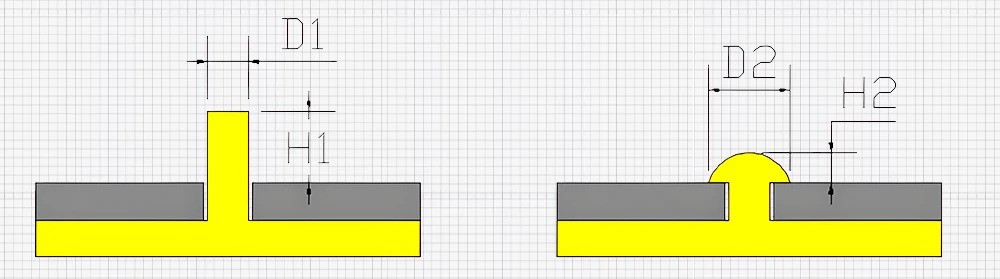

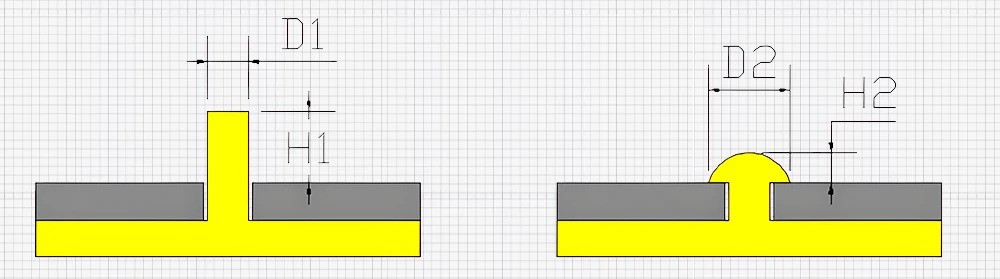

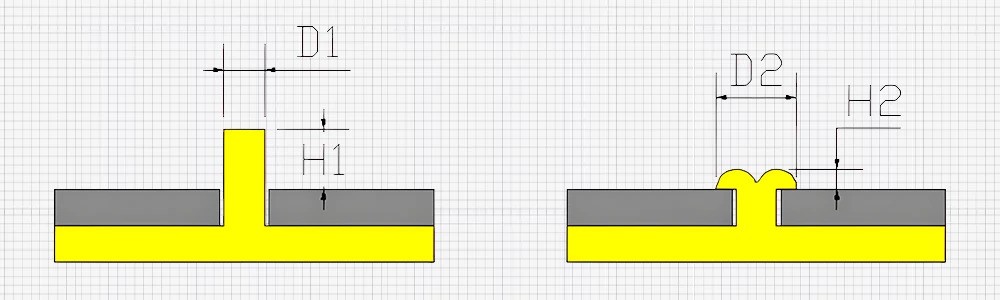

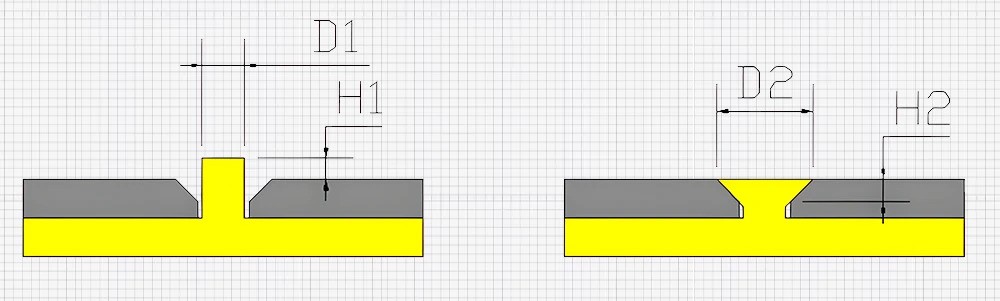

1. Semi-Circular Rivet Head (Large Profile)

This is the most common type. It's used when high strength isn't needed, like in PCBs or decorative parts.

Key points:

Suitable for rivet columns with D1 < 3mm (ideally > 1mm to prevent breakage)

H1 is generally (1.5-1.75) * D1

D2 is around 2 D1, H2 is about 0.75 D1

Specific numbers based on volume conversion: S_head = (85%-95%) * S_column

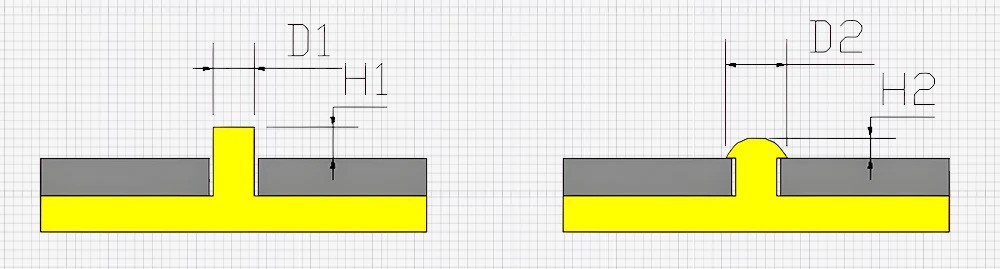

2. Semi-Circular Rivet Head (Small Profile)

This type has a shorter riveting time than the large profile. It's also for low-strength applications, such as FPC cables or metal springs.

Design considerations:

D1 < 3mm, preferably > 1mm

H1 is normally 1.0 * D1

D2 is about 1.5 D1, H2 is around 0.5 D1

Volume conversion: S_head = (85%-95%) * S_column

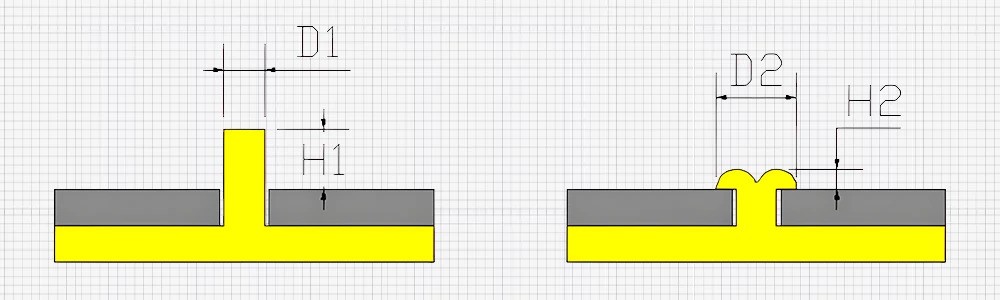

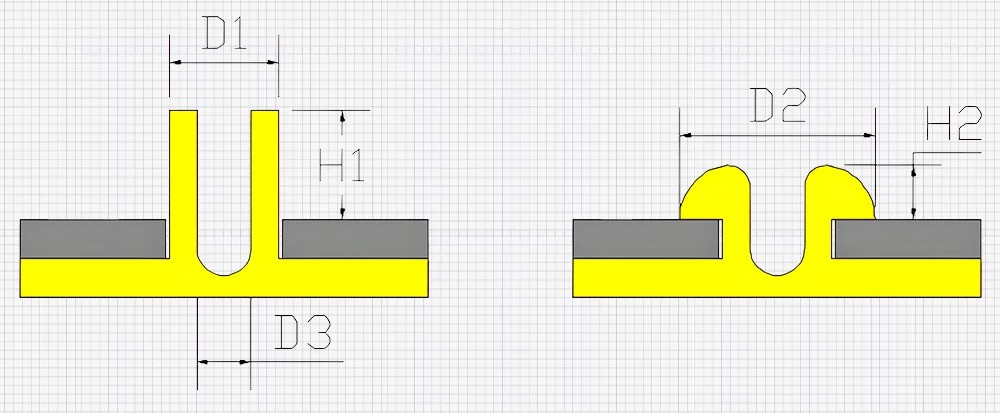

3. Double Semi-Circular Rivet Head

The rivet columns here are slightly larger than the semi-circular types. This design shortens riveting time and improves results. It's used when higher fixing strength is needed.

Key points:

Suitable for rivet columns with D1 between 2-5mm

H1 is typically 1.5 * D1

D2 is about 2 D1, H2 is around 0.5 D1

Volume conversion applies

Rivet column and mold hot riveting head centers must align for neat forming

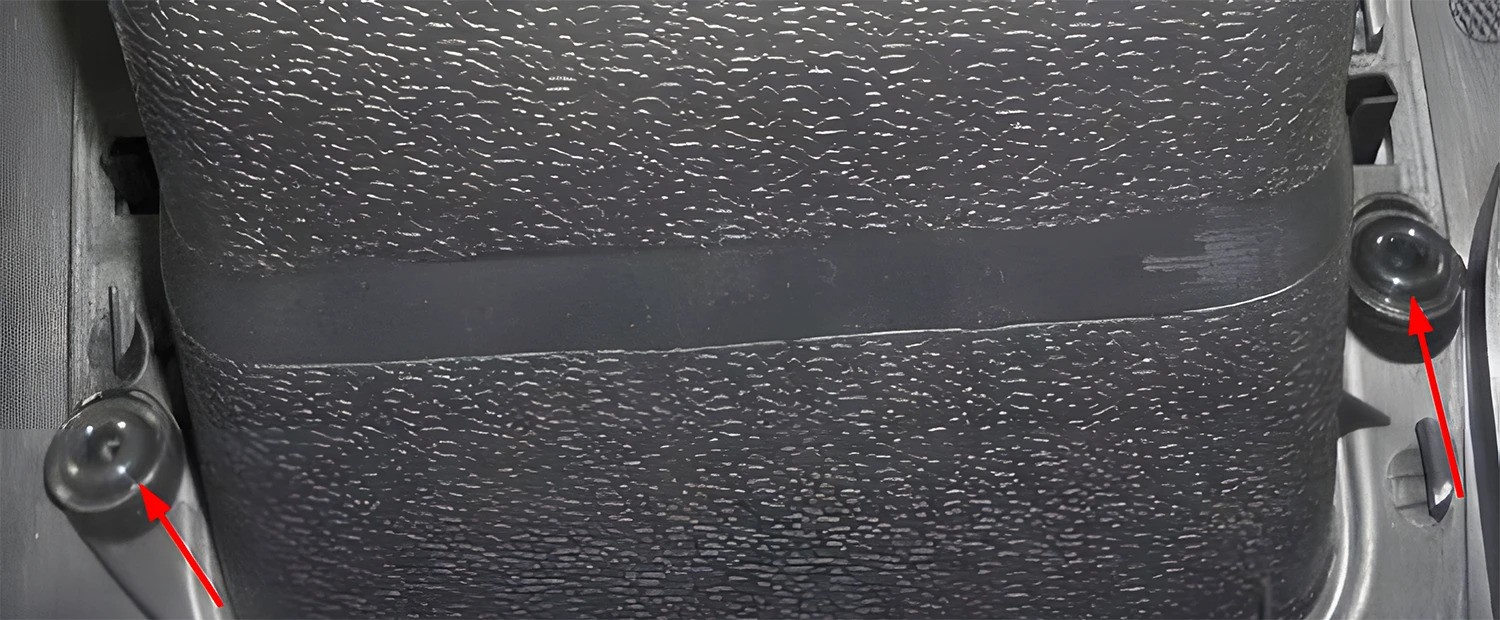

4. Annular Rivet Head

As the rivet column diameter increases, hollow columns are used. They shorten riveting time, improve results, and prevent shrinkage defects. This type is for applications needing higher fixing strength.

Characteristics:

D1 > 5mm

H1 is (0.5-1.5) * D1, smaller value for larger diameters

Inner D is 0.5 * D1 to avoid back shrinkage

D2 is around 1.5 D1, H2 is about 0.5 D1

Volume conversion applies

Even heating of hollow columns helps form qualified heads

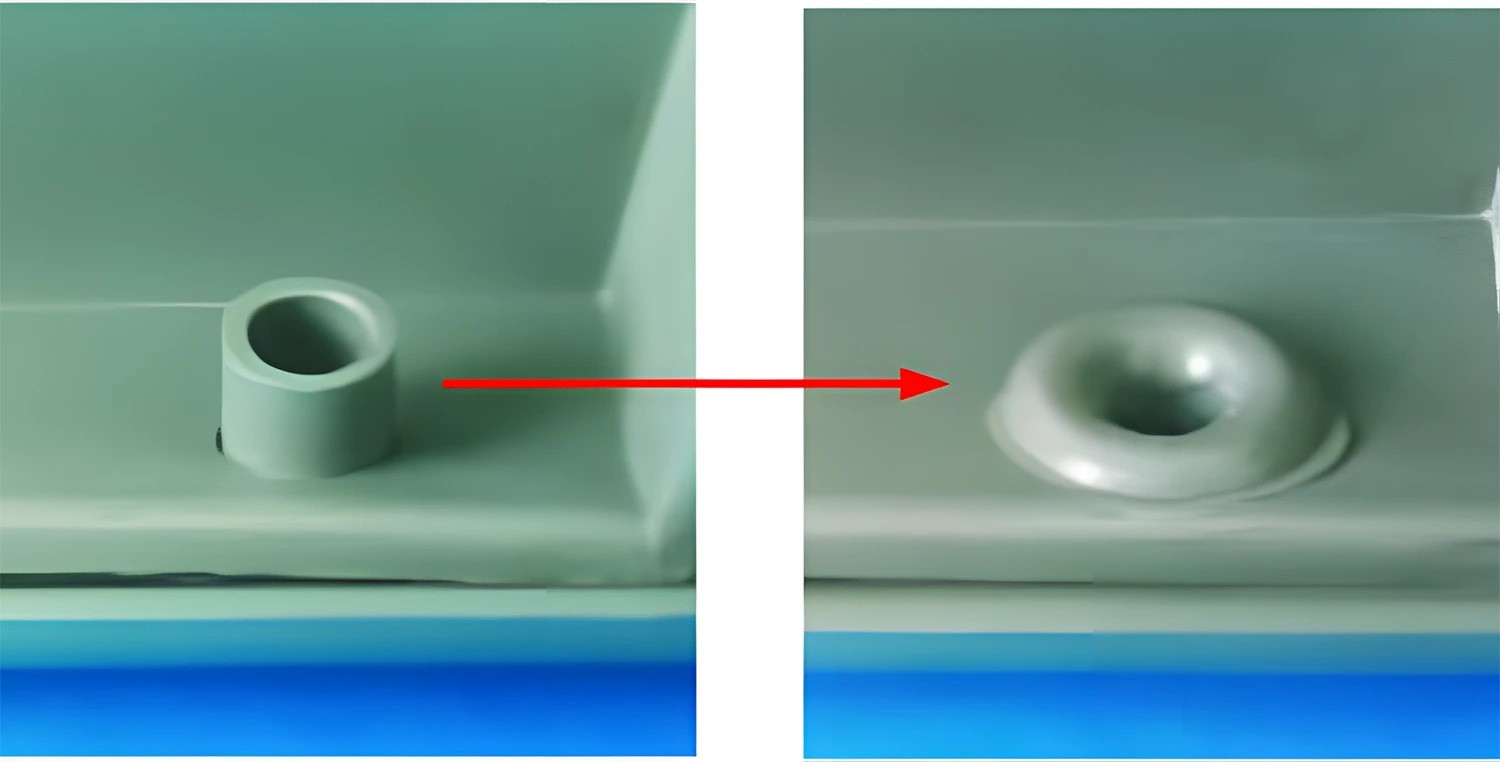

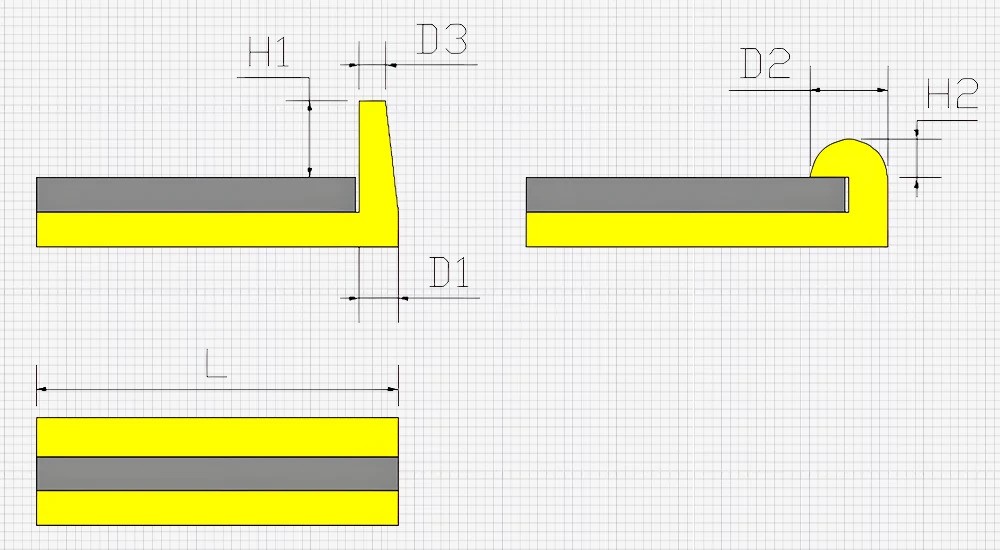

5. Flat Rivet Head

Flat heads are suitable when the formed head shouldn't protrude from the surface.

Design notes:

D1 < 3mm

H1 is typically 0.5 * D1

D2 and H2 based on volume conversion

Connected part needs sufficient thickness for countersinking

Insufficient thickness leads to unreliable connection and inadequate strength

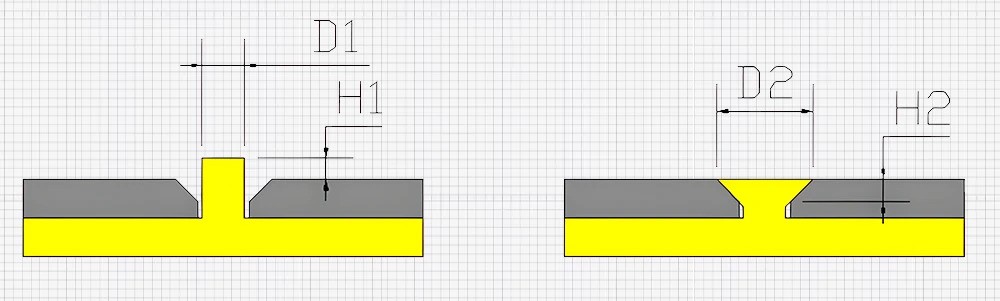

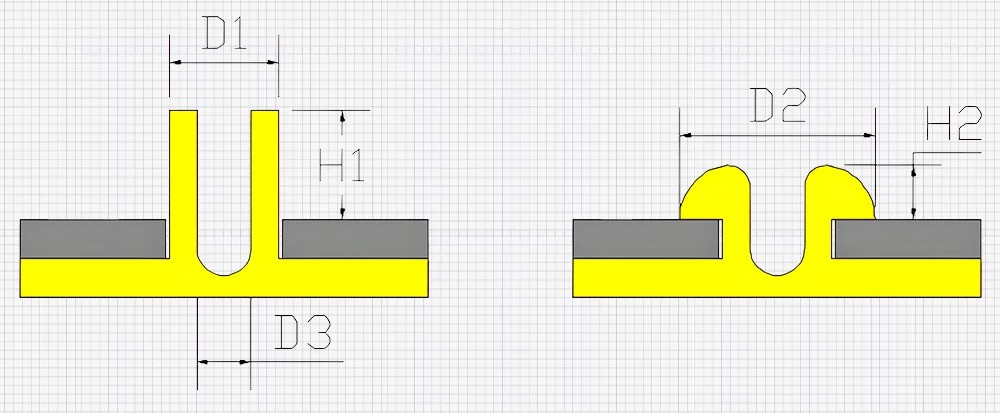

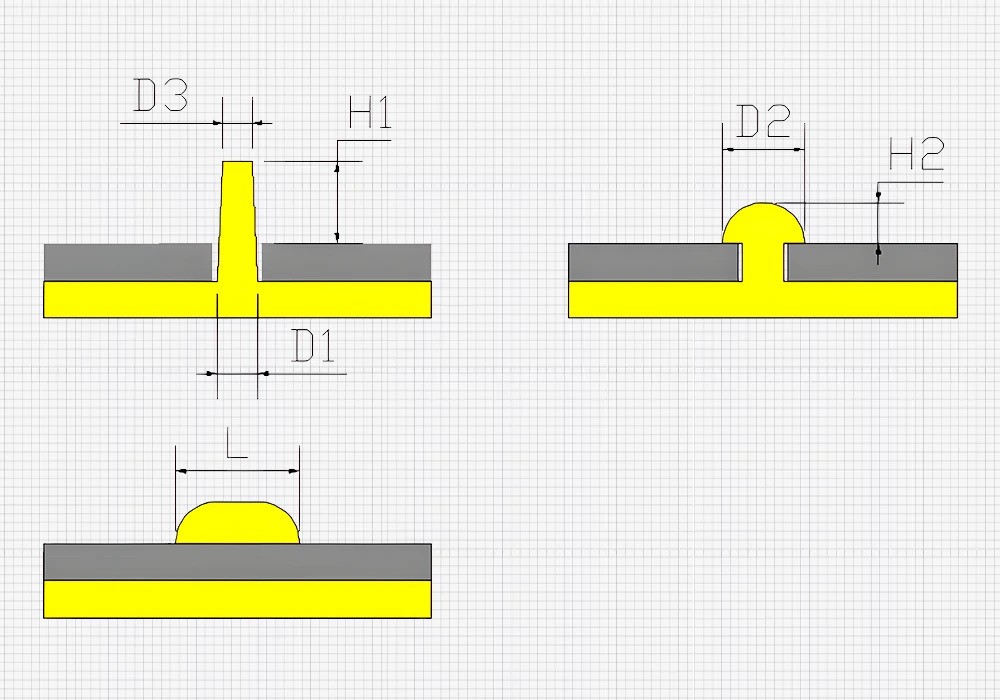

6. Ribbed Rivet Head

Use ribbed heads when you need a larger contact area but don't have space for hollow columns.

Key points:

Base diameter D1 < 3mm, top diameter D3 = (0.4-0.7) * D1

H1 is (1.5-2) * D1, less than column height L

D2 is about 2 D1, H2 is around 1.0 D1

Volume conversion applies

7. Flanged Rivet Head

Flanged heads are ideal for connectors requiring crimping or wrapping.

Design considerations:

Base diameter D1 < 3mm, top diameter D3 = (0.3-0.5) * D1

H1 is (1.5-2) * D1, less than column length L

D2 is normally 2 D1, H2 is about 1.0 D1

Volume conversion applies

Design Considerations for Rivet Columns and Rivet Heads

When designing rivet columns and heads, there are several key factors to keep in mind. Let's explore them in detail.

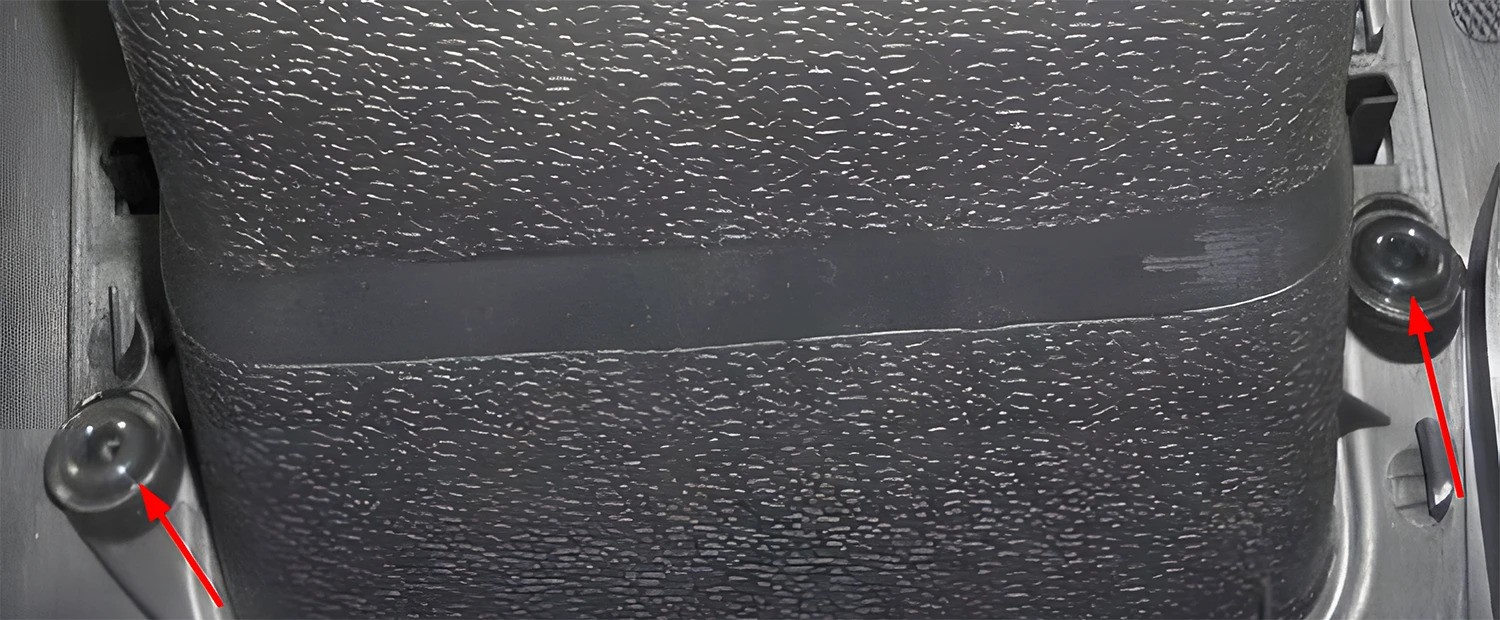

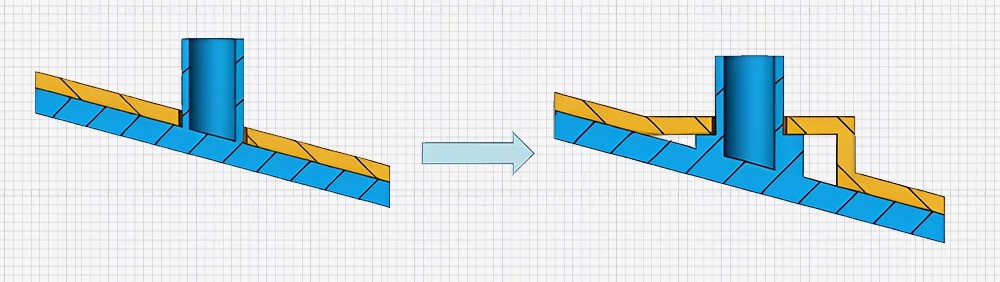

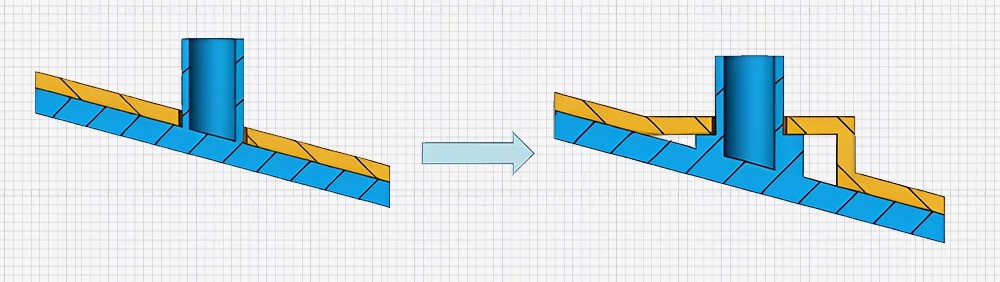

Designing Rivet Columns on Inclined Surfaces or Far from Base

If the rivet column is on an inclined plane or far from the base surface, special design is needed. Here are two methods:

Design Method for Rivet Columns on Inclined Surfaces

For inclined surfaces, the rivet column should be perpendicular to the surface. This ensures proper alignment and secure fastening.

Design Method for Rivet Column Positioned High Above the Base Surface

When the column is high above the base, adding support structures is crucial. They prevent bending or breaking during riveting.

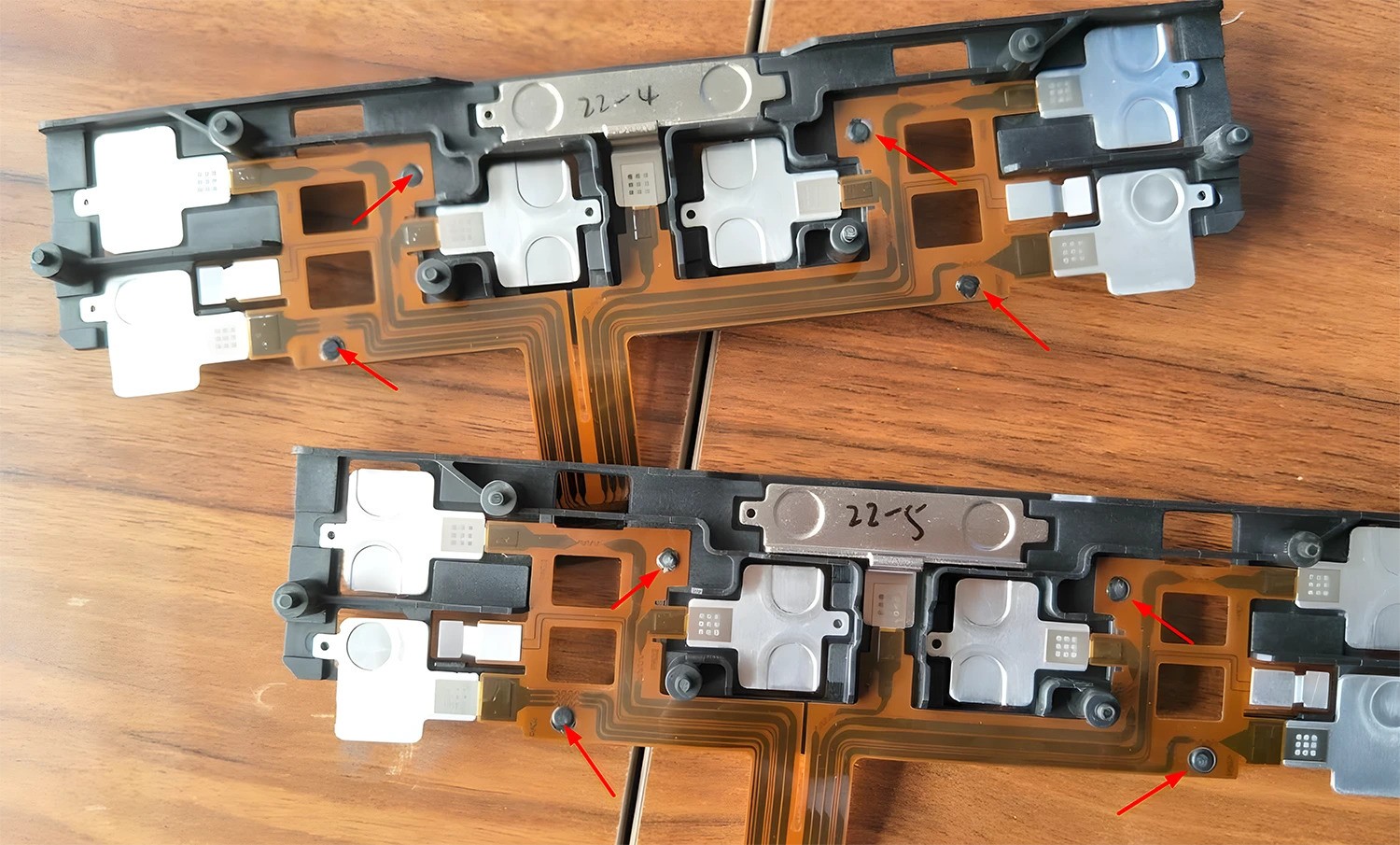

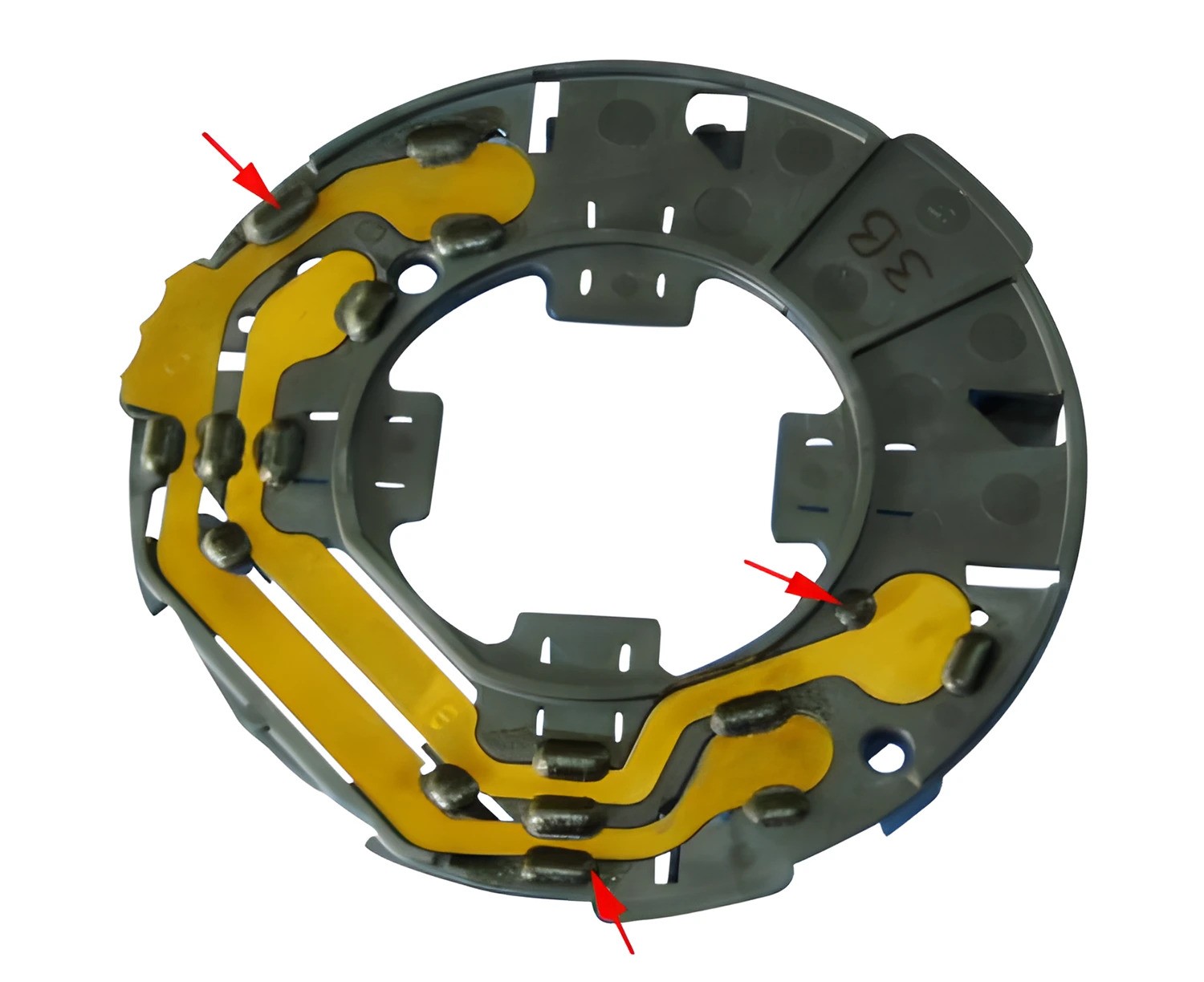

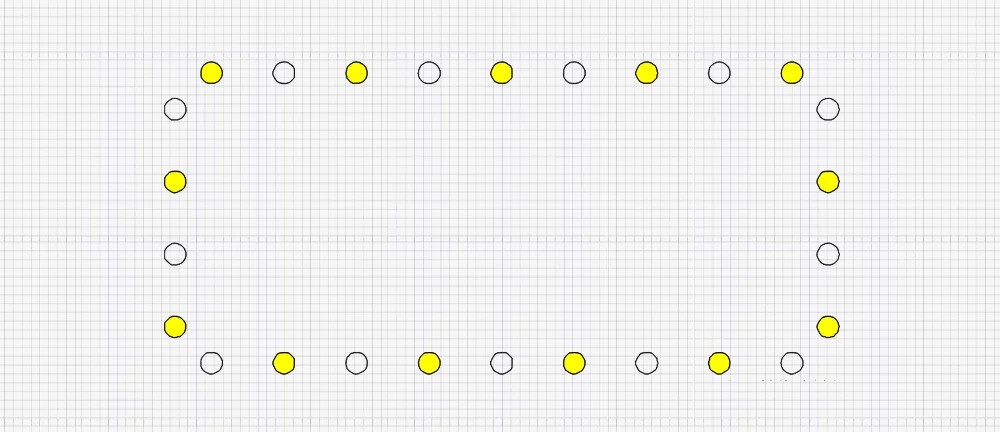

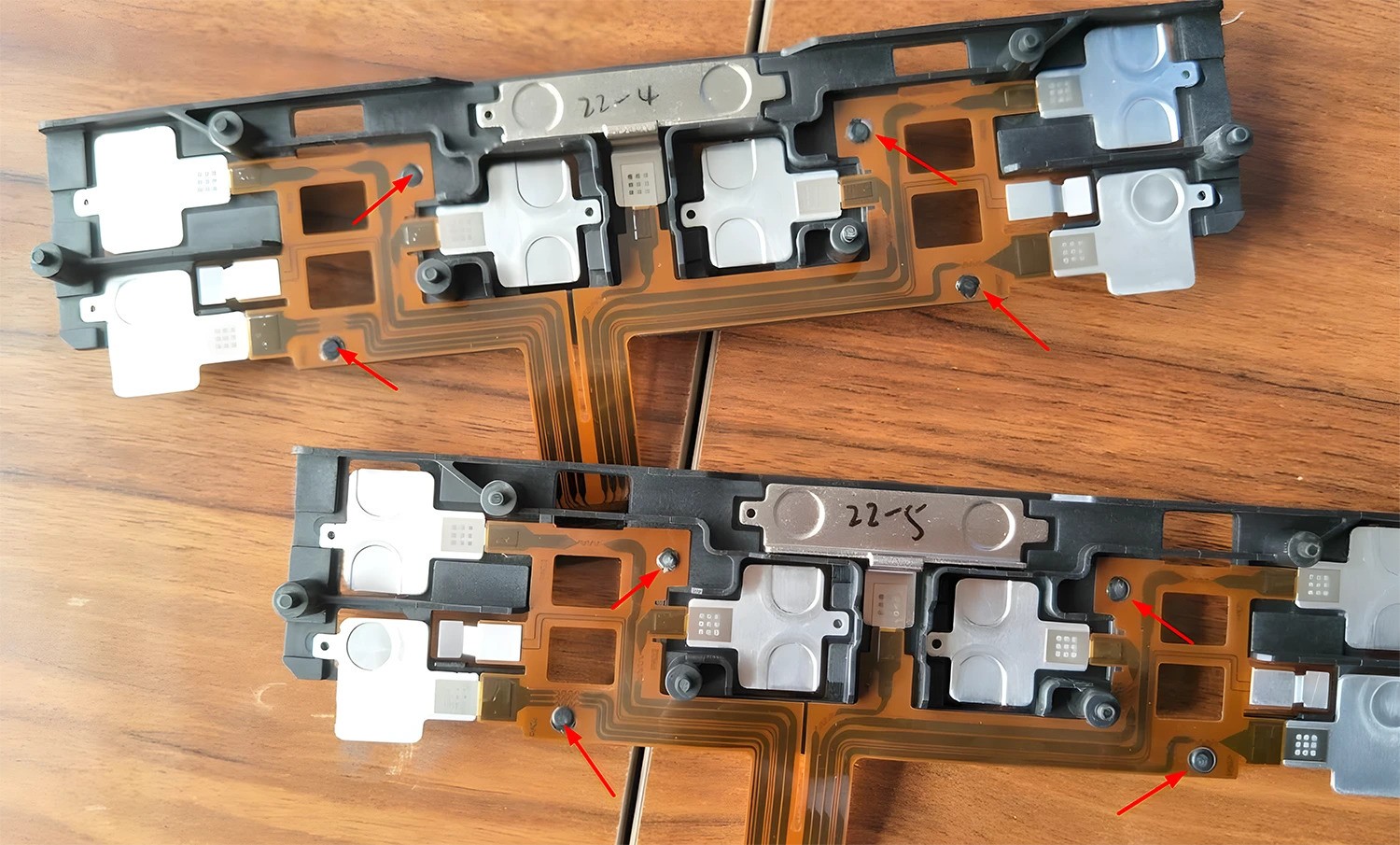

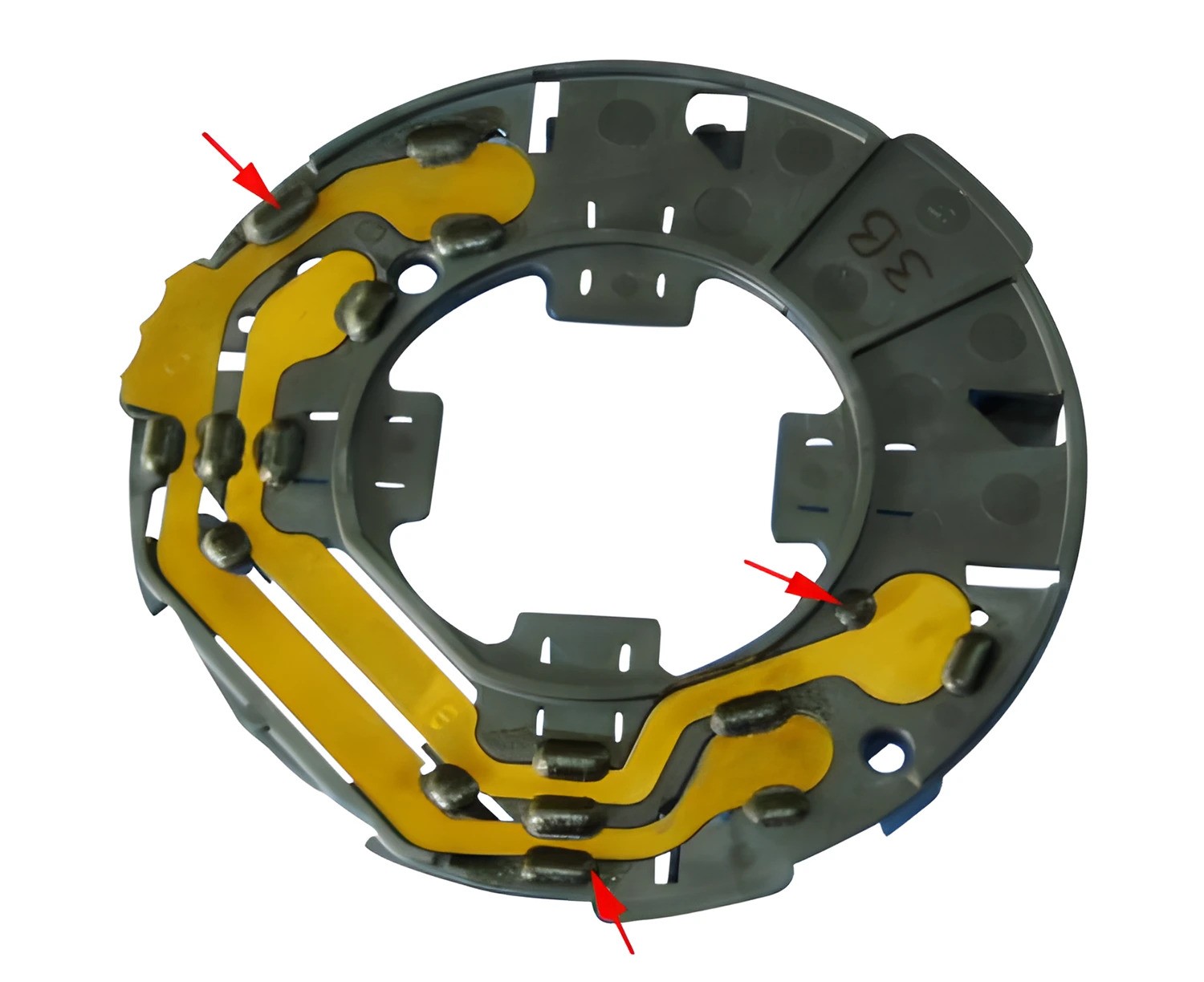

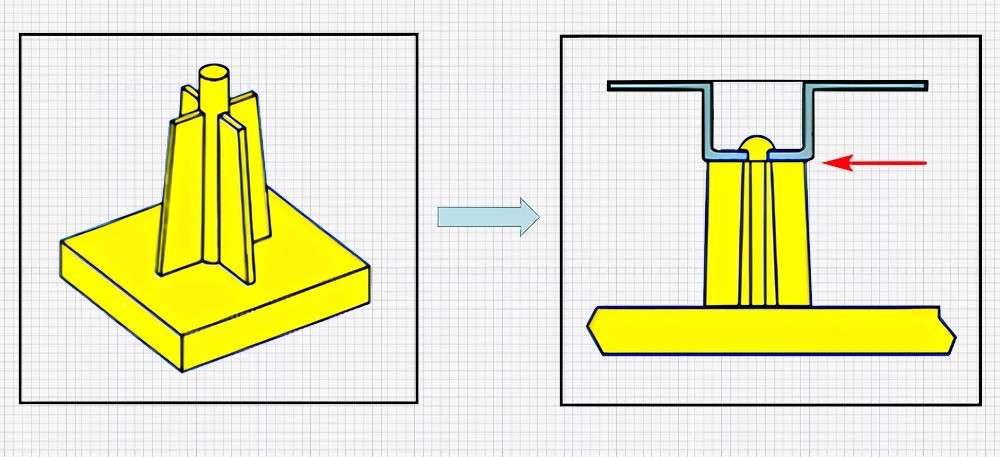

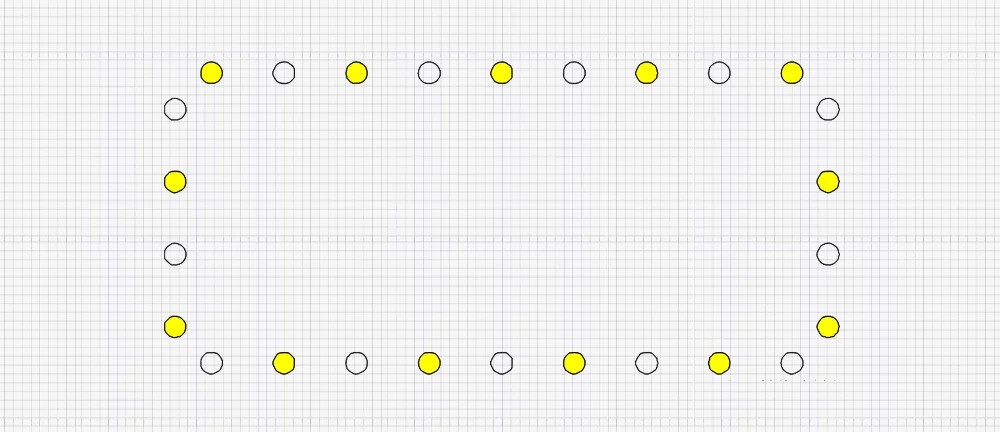

The Importance of Redundancy Design

Plastic riveting creates permanent connections that are difficult to repair if they fail. Incorporating redundancy in the design is essential.

One approach is doubling the number of rivet columns and holes. Initially, only the primary set (e.g., yellow) is used. If repair is needed, the secondary set (e.g., white) provides a backup.

This redundancy gives you a second chance at repair, increasing the overall reliability of the riveted assembly.

Relationship Between Rivet Head and Column Dimensions

The dimensions of the rivet head and column are closely related. Here are some key relationships to consider:

Rivet head diameter (D2) is generally around 2 times the column diameter (D1)

Rivet head height (H2) is typically about 0.75 times D1 for large semi-circular heads, and 0.5 times D1 for small semi-circular heads

The specific dimensions should be based on volume conversion: S_head = (85%-95%) * S_column

This volume conversion ensures that the rivet head has sufficient material to form a strong, secure connection without excessive waste.

Material Adaptability for Plastic Riveting

Not all plastics are suitable for riveting. Let's explore the key factors that determine a material's adaptability.

Thermoplastics vs. Thermosets

Thermoplastics can melt and be reshaped within a specific temperature range. They're ideal for riveting.

In contrast, thermosets harden permanently when heated. They're difficult to rivet using standard methods.

Therefore, product structures often involve thermoplastics when riveting is required.

Amorphous vs. Semi-Crystalline Plastics

Thermoplastics are further divided into amorphous and semi-crystalline types. Each has unique characteristics that affect riveting.

Amorphous (Non-Crystalline) Plastics

Disordered molecular arrangement

Gradual softening and melting at glass transition temperature (Tg)

Suitable for all three riveting processes (hot melt, hot air, ultrasonic)

Semi-Crystalline Plastics

Ordered molecular arrangement

Distinct melting point (Tm) and recrystallization point

Remain solid until reaching melting point, then quickly solidify when cooled

More suitable for hot melt riveting due to combined heating and forming

Regular spring-like structure absorbs ultrasonic energy, making ultrasonic riveting challenging

Higher melting points require more ultrasonic energy to melt

Careful design considerations needed for ultrasonic riveting (higher amplitude, joint design, welding head contact, distance, fixtures)

Minimize initial contact between rivet column top and welding head to concentrate energy

Impact of Fillers (e.g., Glass Fibers)

Fillers can significantly affect a plastic's riveting performance. Let's look at glass fibers as an example.

Key points:

Large difference in melting points between plastic and glass fibers

Hot melt riveting: Precise temperature control (±10°) crucial

High temperatures cause glass fiber precipitation, adhesion, and rough surfaces

Low temperatures lead to cracks and cold forming

Ultrasonic riveting: More vibration energy needed to melt plastic

Filler content guidelines:

<10%: Minimal effect on material properties, beneficial for soft materials (PP, PE, PPS)

10-30%: Reduces riveting strength

-

30%: Significantly impacts riveting performance

Other material properties affecting ultrasonic riveting:

Hardness: Higher hardness generally improves riveting

Melting point: Higher melting points require more ultrasonic energy

Purity: Higher purity enhances riveting, while impurities in recycled materials reduce performance

Plastic Materials Used in Riveting

Selecting the right plastic material is crucial for successful riveting. Let's take a closer look at some common options.

Low Density Polyethylene (LDPE)

LDPE has a low density due to its loosely packed molecular structure. It's flexible yet tough.

Key properties:

Polypropylene (PP)

PP is widely used across industries, from automotive to packaging. It offers good chemical resistance and electrical insulation.

Applications:

Nylon

Nylon, particularly Nylon 6/6, is popular in manufacturing. Its low friction makes it ideal for gears and bearings.

Characteristics:

Resists most chemicals, but can be attacked by strong acids, alcohols, and alkalis

Poor resistance to dilute acids, excellent resistance to oils and greases

Used for snap rivets, unscrewing rivets, and push-in knob head rivets

Acetal (Polyoxymethylene, POM)

Acetal, or POM, is strong, rigid, and resistant to moisture, heat, chemicals, and solvents. It has good electrical insulation properties.

Uses:

Gears, bushings, automotive door handles

Quarter turn panel fasteners

Panel strikers

Snap-in flush top rivets

Polysulfone (PSU)

PSU is used in specialty applications due to its high thermal and mechanical capacity.

Key features:

Comparison of Material Properties

Here's a table comparing the properties of these materials:

| Properties | LDPE | PP | Nylon 6/6 | Acetal | PSU |

| Tensile Strength (psi) | 1,400 | 3,800-5,400 | 12,400 | 9,800-10,000 | 10,200 |

| Impact Toughness (J/m²) | No break | 12.5-1.2 | 1.2 | 1.0-1.5 | 1.3 |

| Dielectric Strength (kV/mm) | 16-28 | 20-28 | 20-30 | 13.8-20 | 15-10 |

| Density (g/cm³) | 0.917-0.940 | 0.900-0.910 | 1.130-1.150 | 1.410-1.420 | 1.240-1.250 |

| Max. Continuous Service Temp. | 212°F (100°C) | 266°F (130°C) | 284°F (140°C) | 221°F (105°C) | 356°F (180°C) |

| Thermal Insulation (W/m·K) | 0.320-0.350 | 0.150-0.210 | 0.250-0.250 | 0.310-0.370 | 0.120-0.260 |

Keep in mind that additives and stabilizers can enhance certain properties. For example, UV stabilizers can improve nylon's outdoor performance.

How to Choose the Right Size Rivet

General Rule of Thumb

A simple approach is to base the rivet diameter on the thickness of the plates being joined. Here's the rule of thumb:

Rivet Diameter = 1/4 × Plate Thickness

This ratio ensures that the rivet is proportional to the material it's holding together. It's also known as the grip range.

Factors to Consider

While the general rule is a good starting point, there are other factors to keep in mind:

Material properties

Joint design

Type of joint (lap, butt, etc.)

Loading conditions (shear, tension, etc.)

Aesthetics

Visible or hidden joint

Flush or protruding head

Assembly process

These factors can influence the optimal rivet size. In some cases, you may need to deviate from the general rule to achieve the best results.

Examples and Calculations

Let's look at a few examples to illustrate the sizing process.

Example 1:

Example 2:

Plate thickness: 10 mm

Rivet diameter = 1/4 × 10 mm = 2.5 mm

Round up to the nearest standard size, e.g., 3 mm

Example 3:

Plate thickness: 2 mm (thin plates)

Rivet diameter = 1/4 × 2 mm = 0.5 mm

Increase to a minimum practical size, e.g., 1 mm, for ease of installation and strength

Remember, these calculations provide a starting point. Always consider the specific requirements of your application and make adjustments as needed.

| Plate Thickness (mm) | Rivet Diameter (mm) |

| 1-2 | 1 |

| 3-4 | 1-2 |

| 5-8 | 2-3 |

| 9-12 | 3-4 |

| 13-16 | 4-5 |

Conclusion

In this guide, we explored the various riveting processes for plastic parts, including hot melt, hot air, and ultrasonic methods. We also discussed different rivet head types and their specific applications.

Choosing the right riveting process and materials is crucial for ensuring strong and durable connections in plastic assemblies. The correct selection can significantly impact the longevity and performance of your products.

Now that you have this knowledge, we encourage you to apply these insights to your projects. By doing so, you’ll ensure better outcomes and more reliable assemblies in your manufacturing endeavors. Contact us today!