Have you ever wondered why some injection-molded parts come out smooth and perfect, while others have unsightly blemishes or get stuck in the mold? The answer lies in draft angles – a critical aspect of injection mold design that can make or break your product's quality.

In this post, you'll learn about the importance of draft angles, their benefits, and best practices. Stay tuned to master this essential aspect of injection molding.

What is a Draft Angle?

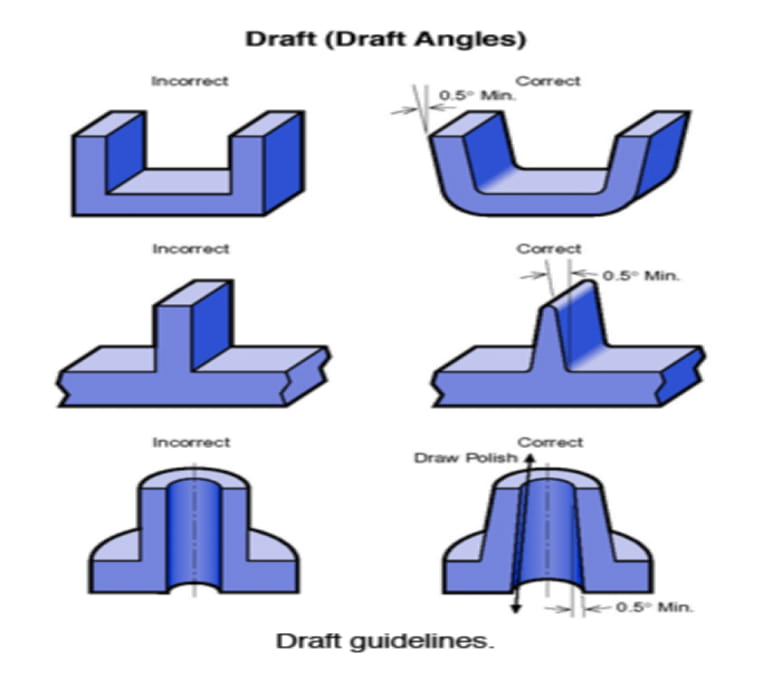

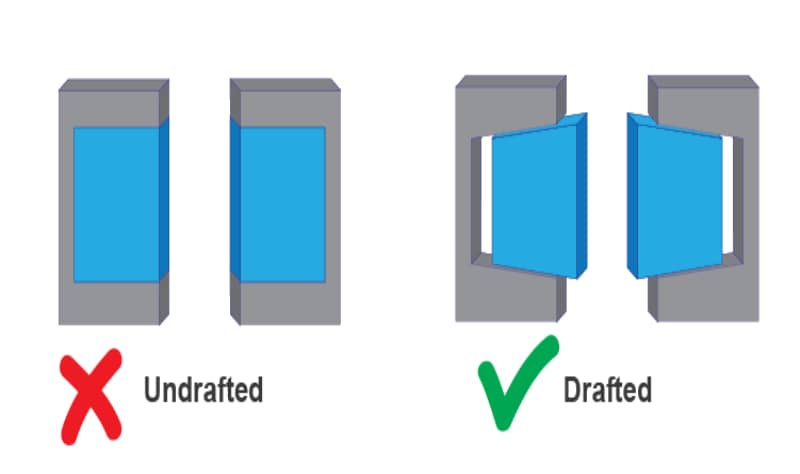

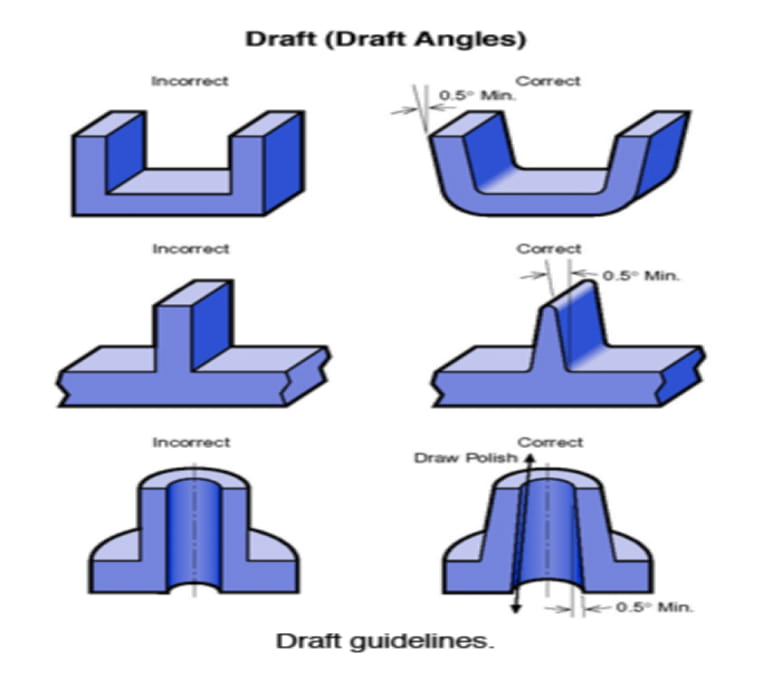

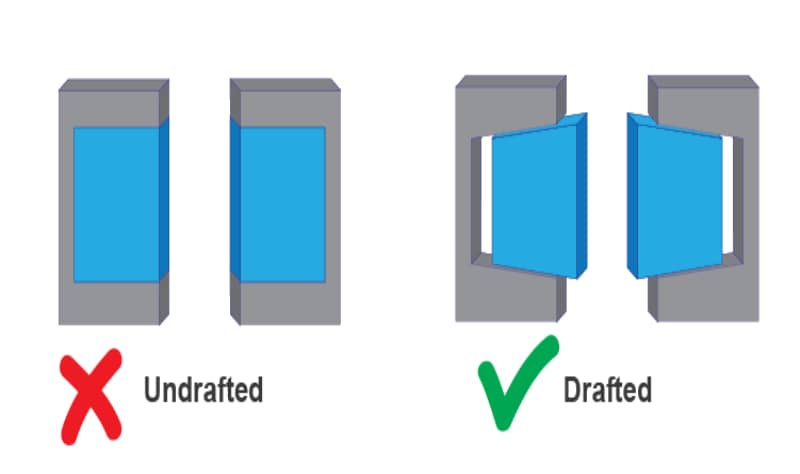

A draft angle is a slight taper or slope added to the walls of an injection-molded part. It's a crucial design element that ensures the part can be easily released from the mold after cooling.

Why are draft angles so important? Here's why:

They reduce friction between the part and the mold during ejection

They minimize the risk of part deformation or damage

They help maintain the part's desired shape and dimensions

They prolong the life of the mold by reducing wear and tear

Without proper draft angles, parts can stick to the mold, leading to:

So, how much draft do you need? It depends on several factors, such as:

As a general rule of thumb, aim for a minimum draft angle of 1° to 2° per side. For deeper parts or textured surfaces, you may need to increase it to 3° or more.

Why is Draft Angle Critical for Injection Molding?

Have you ever tried to pull a tightly fitted object out of a container? It can be a real struggle, right? The same principle applies to injection molding. Without proper draft angles, parts can get stuck in the mold, leading to a host of problems.

Reduces Friction and Damage During Part Ejection

One of the primary reasons draft angles are so important is that they reduce friction between the part and the mold during ejection. This helps to prevent:

Part deformation

Surface scratches

Ejector pin marks

By allowing the part to release smoothly from the mold, draft angles minimize the risk of damage and ensure a higher quality finished product.

Minimizes Wear and Tear on the Mold

Molds are a significant investment, and you want them to last as long as possible. Draft angles play a crucial role in reducing wear and tear on the mold during the ejection process. They help to:

Distribute ejection forces evenly

Prevent abrasion and gouging

Extend the mold's lifespan

Ensures Smooth, Uniform, and Unscratched Finishes

When it comes to injection molding, appearance matters. Draft angles help to maintain the desired surface finish of your parts by:

Preventing drag marks and scratches

Ensuring a consistent, uniform finish

Preserving the integrity of textures and patterns

Reduces Cooling Time and Production Costs

Draft angles also play a role in optimizing the injection molding process itself. They can help to:

Reduce cooling time by allowing parts to release from the mold more easily

Eliminate the need for complex ejection setups

Lower overall production costs by increasing efficiency and reducing scrap rates

In short, draft angles are a small but mighty design feature that can have a big impact on the success of your injection molding project. They ensure better part quality, longer mold life, and a more efficient production process – all of which translate to cost savings and a better bottom line.

How to Determine the Optimal Draft Angle

Choosing the right draft angle for your injection-molded part can feel like a balancing act. Too little draft, and you risk part ejection issues. Too much, and you may compromise the part's functionality or appearance. So, how do you find that sweet spot? Here are some key factors to consider:

Wall Thickness

Thinner walls typically require larger draft angles to prevent warping and ensure smooth ejection. As a general rule, aim for:

| Wall Thickness | Minimum Draft Angle |

| 0.040 in. | 1° |

| 0.060 in. | 0.5° |

| 0.080 in. | 0.5° |

| >0.100 in. | 0.5° |

Material Selection

Different materials have different shrink rates and ejection requirements. For example:

Ejection Mechanism

The type of ejection system used (e.g., pins, sleeves, or blades) can impact the required draft angle. Discuss this with your molder to ensure compatibility.

Surface Finish and Texture

Textured surfaces generally need more draft than smooth surfaces. A good rule of thumb is to add 1.5° of draft per 0.001" of texture depth.

Wall Depth

Deeper walls require larger draft angles to prevent sticking and ease ejection. Here are some guidelines based on wall depth:

| Wall Depth | Minimum Draft Angle |

| 0.25 in. | 0.5° |

| 0.5 in. | 1° |

| 0.75 in. | 2° |

| 1 in. | 2° |

| 1.5 in. | 2° |

| 2 in. | 2° |

| FEATURE DEPTH | MINIMUM THICKNESS/DRAFT |

|

|

|

| 0.25 in. | 0.040 in./0.5° | | | |

| 0.5 in. | 0.040 in./1° | 0.060 in./0.5° | | |

| 0.75 in. | 0.040 in./2° | 0.060 in./1° | 0.080 in./0.5° | |

| 1 in. | | 0.060 in./2° | 0.080 in./1° | >0.100 in./0.5° |

| 1.5 in. | | | 0.080 in./2° | >0.100 in./1° |

| 2 in. | | | | >0.100 in./2° |

General Guidelines for Draft Angles

Here are some general rules for determining draft angles:

Standard Draft: 1.5 to 2 degrees is ideal for most parts up to 2 inches deep.

Depth Adjustment: Add 1 degree for every inch of part depth beyond 2 inches.

Directional Draft: Always draft towards the "top" of the mold.

Textured Parts: Add 1.5 degrees per 0.001 inch of texture depth.

Component Drafting: All parts of a piece should have a draft angle.

Metal-on-Metal Molding: Use at least 3 degrees of draft.

Dual-Sided Drafting: Parts with a middle parting line need draft on both sides.

Vertical Surfaces: Include a minimum of 0.5 degrees of draft.

Best Practices for Designing Draft Angles

Designing for draft can feel like an art as much as a science. To help you navigate the process, we've compiled some best practices gleaned from years of injection molding experience.

Start Early

One of the most important things you can do is incorporate draft angles early in the design process. This helps to:

Avoid costly redesigns later on

Ensure your part can be manufactured efficiently

Identify potential ejection issues before they become problems

Use a Core-Cavity Approach

If your part requires a smooth, high-quality outer surface, consider using a core-cavity approach. This involves:

This approach allows the part to shrink away from the cavity surface during cooling, ensuring a clean release and a pristine finish.

Draft All Vertical Surfaces

Every vertical surface on your part should have some degree of draft, including:

Ribs

Gussets

Louvers

Bosses

Snaps

Even if you can't achieve the ideal draft angle, remember: any draft is better than no draft at all!

Consider the Reference Face

When adding draft to your part, think carefully about the reference face from which the draft will be applied. This can impact:

Choose a reference face that minimizes any negative effects on the part's form, fit, and function.

Don't Forget Side-Action Features

If your part has features that require side-action in the mold (e.g., holes, slots, or undercuts), be sure to add draft to these surfaces as well. This will ensure clean, easy ejection and prevent damage to the mold.

More Draft for Abrasive Materials

Some materials, like glass-filled nylon or polycarbonate, can be abrasive and cause wear on the mold over time. For these materials, it's best to use slightly larger draft angles (3°+) to minimize friction and extend the life of the tool.

Troubleshooting Draft Angle Issues

Even with careful planning and design, draft angle issues can still arise during the injection molding process. Here's how to identify and address them.

Identifying Insufficient Draft

How can you tell if your part has insufficient draft? Look for these telltale signs:

Difficulty ejecting the part from the mold

Visible drag marks or scratches on the part surface

Deformation or warping of the part after ejection

Excessive wear or damage to the mold cavity

If you notice any of these issues, it's time to take a closer look at your draft angles.

Correcting Draft in Design

The best time to address draft angle issues is during the design phase. Here's what you can do:

Consult with your injection molder early on

Use CAD tools to analyze and optimize draft angles

Consider alternative part geometries or orientations

Adjust the location of the parting line or gate

Making changes to your design before cutting the mold can save significant time and money in the long run.

Modifying Draft During Mold Manufacturing

If draft issues are identified after the mold has been manufactured, all is not lost. There are still some options for modifying the draft angles:

Grinding or polishing the mold cavity to increase draft

Adding a taper to the ejector pins or sleeves

Using a mold coating to reduce friction and sticking

These modifications can be effective, but they do add cost and complexity to the molding process. It's always better to address draft issues as early as possible.

| Issue | Possible Solution |

| Sticking or drag marks | Increase draft angle |

| Warping or deformation | Adjust draft direction or parting line |

| Mold damage or wear | Use more draft for abrasive materials |

Conclusion

Draft angles are crucial for injection molding. They reduce friction, ensuring smooth part release. They also protect molds from wear and tear. Using the correct draft angle enhances the surface finish and reduces cooling time, lowering production costs.

Incorporating draft angles from the start of the design process is vital. It prevents defects, speeds up production, and maintains part quality. Always consider material, wall thickness, and texture when determining the draft angle. Remember, any draft is better than none for successful molding.