Injection molding shapes everyday products, from toys to medical devices. Choosing the right mold is essential for quality and efficiency. In this post, you'll learn the key differences between 2-plate and 3-plate molds, helping you select the best option for your needs.

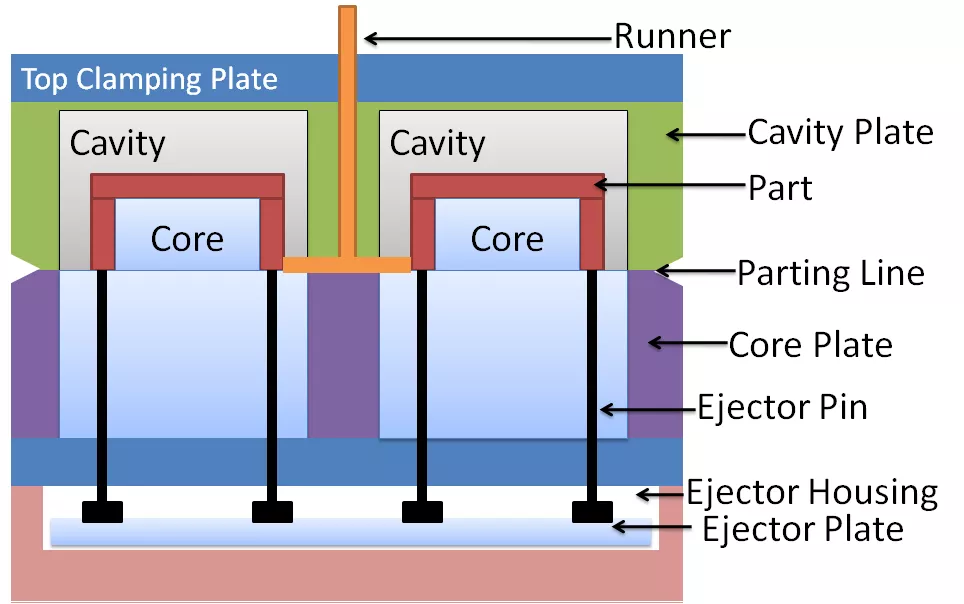

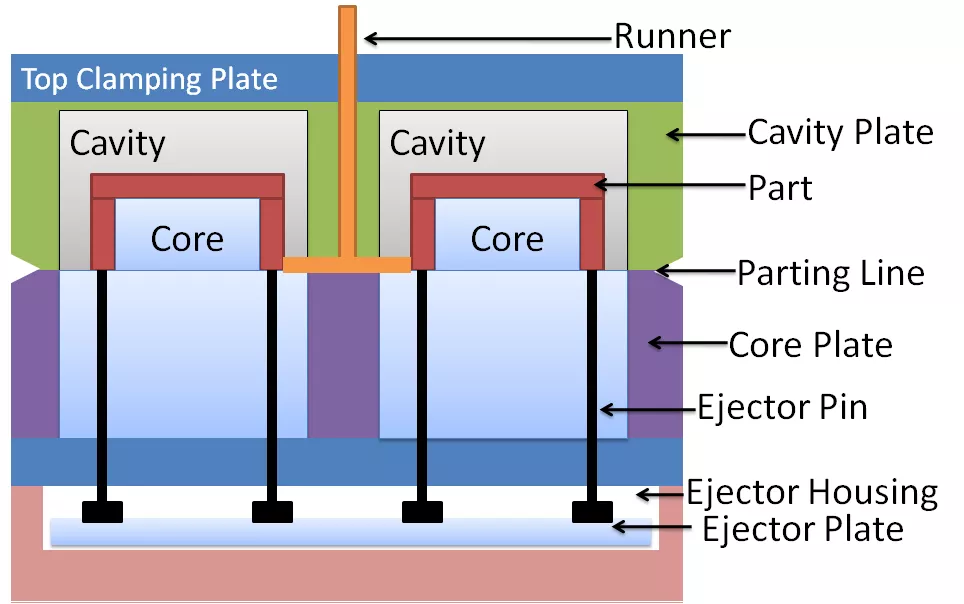

What is a 2-Plate Mold?

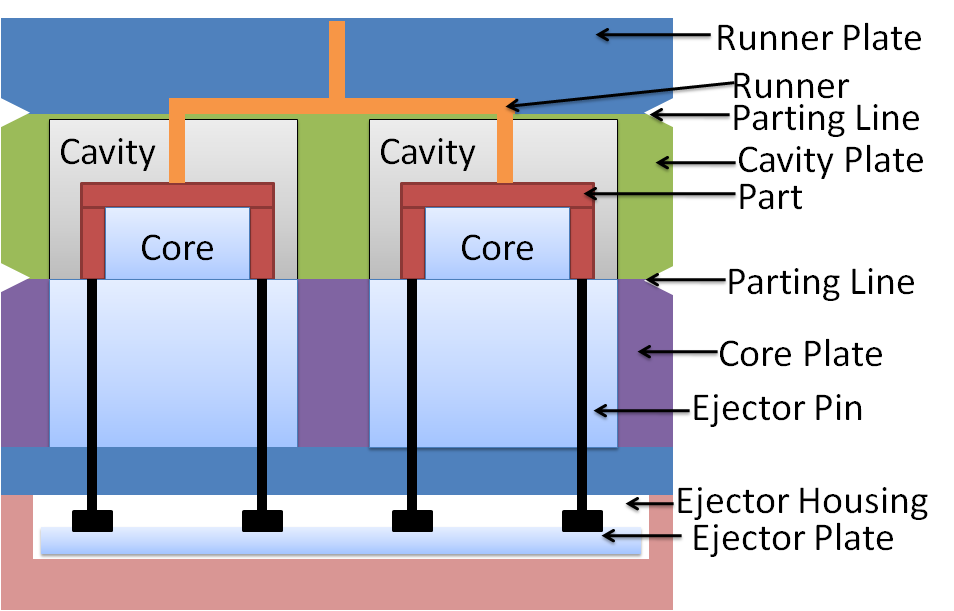

A 2-plate mold, also known as a two-plate mold, is a type of injection molding mold used to manufacture plastic parts. It consists of two main plates: the cavity plate and the core plate.

The cavity plate contains the impression of the final part's outer shape and surface finish. The core plate complements the cavity plate and creates the inner shape of the part.

The injection molding process with a 2-plate mold involves:

Closing the mold, bringing the cavity and core plates together

Injecting plastic material into the cavity under high pressure

Allowing the plastic to fill the cavity and solidify

Opening the mold and ejecting the finished part

Advantages of 2-Plate Molds

Simple design leads to cost-effective manufacturing

Ideal for high-volume production due to shorter cycle times

Well-suited for molding parts with flat or simple geometries

Disadvantages of 2-Plate Molds

Limited flexibility for parts with complex designs or multiple gating points

Single gating point may cause cosmetic defects

Parting line and gate alignment is crucial in multi-cavity molds

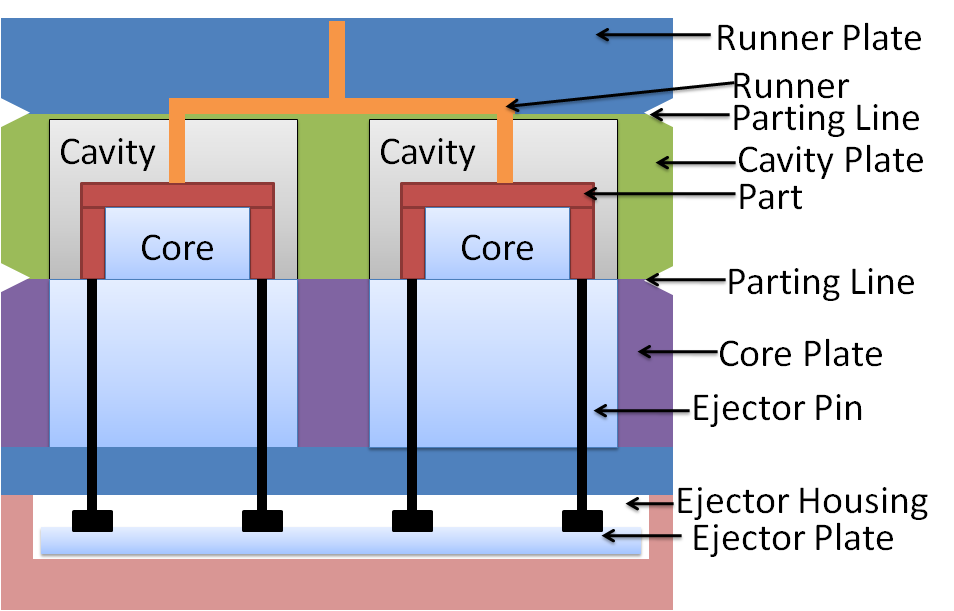

What is a 3-Plate Mold?

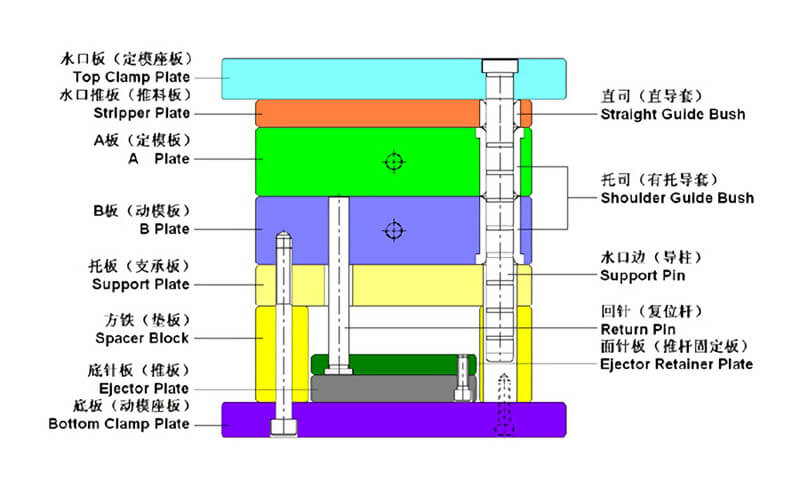

A 3-plate mold, or three-plate mold, is an injection molding tool used to create plastic parts. It has an additional plate called the runner plate or gating plate.

This extra plate sets it apart from the simpler 2-plate mold. The 3-plate mold consists of:

Cavity plate: Contains the impression of the part's outer shape and surface

Core plate: Defines the inner shape of the part

Runner plate: Creates a separate channel for plastic flow into the cavity

The injection molding process with a 3-plate mold involves:

Closing the mold, bringing all plates together

Injecting plastic into the runner system under high pressure

Allowing the plastic to flow through multiple gating points into the cavity

Opening the mold and ejecting the finished part

Advantages of 3-Plate Molds

Versatile for molding complex parts with undercuts or multiple gating points

Reduces cosmetic defects by controlling material flow and strategic gate placement

Offers greater design flexibility and improved part ejection

Disadvantages of 3-Plate Molds

More complex and costly to design and manufacture than 2-plate molds

Longer cycle times due to added complexity

Increased material waste from the runner system

Key Differences Between 2-Plate and 3-Plate Molds

When choosing between 2-plate and 3-plate molds, it's crucial to understand their key differences.

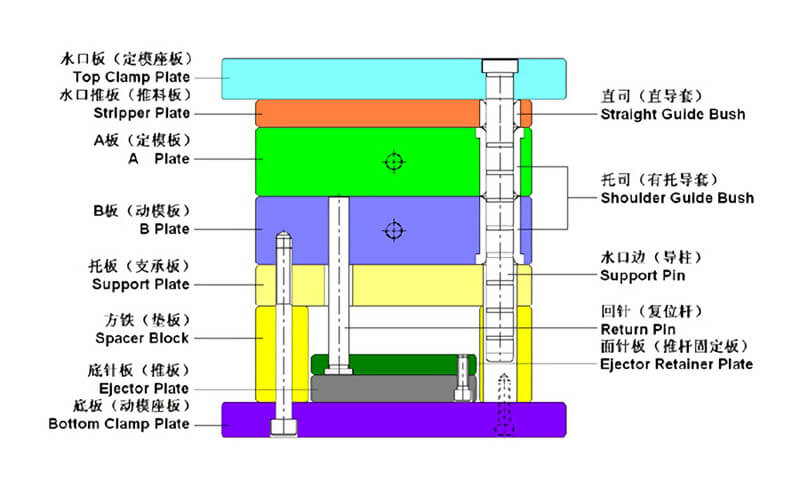

Structural Differences

2-plate molds have a single parting line where the mold splits. In multi-cavity 2-plate molds, the gate and runner are located in this parting plane. 3-plate molds have two parting lines. The additional parting line allows for the runner system to be separated from the molded part.

Functionality Differences

2-plate molds open and close in a single step. When the mold opens, the part and runner remain on the moving side of the mold. The part is then ejected from the same parting surface. 3-plate molds have a more complex opening sequence:

The mold opens, separating the cavity and core plates from the runner plate

The gate breaks away from the part as the runner plate retracts

The part is ejected from the cavity and core plates In 2-plate molds, gate removal is a manual process. 3-plate molds automate this step, as the gate breaks off during the mold opening sequence.

Design Flexibility

3-plate molds offer greater design flexibility. They allow for multiple gating points, making them suitable for complex parts with undercuts or intricate geometries. 2-plate molds are more restrictive in design. They typically have a single gating point, limiting their ability to accommodate complex features or multiple gates.

| Feature | 2-Plate Mold | 3-Plate Mold |

| Parting Lines | Single | Double |

| Runner & Gate Position | In parting plane | Separate from parting plane |

| Mold Opening | Single step | Multi-step sequence |

| Gate Removal | Manual | Automatic |

| Design Flexibility | Limited | Enhanced |

Common Applications

2-plate and 3-plate molds are used across various industries to manufacture a wide range of products. Let's explore some typical applications for each mold type.

Common Applications for 2-Plate Molds

Industry Examples

2-plate molds are commonly used in industries that produce simple plastic parts and consumer goods. These include:

Household items (e.g., kitchenware, storage containers)

Toys and games

Packaging (e.g., bottles, caps, lids)

Product Types

Flat parts and low-precision components are well-suited for 2-plate molding. Examples include:

Simple plastic trays and lids

Promotional items (e.g., keychains, badges)

Basic mechanical components (e.g., gears, pulleys)

Common Applications for 3-Plate Molds

Industry Examples

3-plate molds are often used in industries that require high-precision manufacturing and complex part geometries. Typical industries include:

Automotive (e.g., interior trim, functional components)

Medical (e.g., devices, implants)

Aerospace (e.g., lightweight, intricate parts)

Product Types

Complex shapes and intricate geometries are best suited for 3-plate molding. Specific products include:

Multi-component assemblies

Parts with undercuts or side actions

High-precision gears and mechanical components

| Mold Type | Common Industries | Typical Products |

| 2-Plate | - Consumer goods

- Packaging

- Toys and games | - Simple plastic parts

- Flat components

- Low-precision items |

| 3-Plate | - Automotive

- Medical

- Aerospace | - Complex shapes

- Intricate geometries

- High-precision parts |

Factors to Consider When Choosing Between 2-Plate and 3-Plate Molds

Selecting the right mold type for your injection molding project is crucial. Let's explore the key factors you should consider when deciding between 2-plate and 3-plate molds.

Part Geometry and Design Complexity

The complexity of your part's design plays a significant role in mold selection. 2-plate molds are suitable for simple, flat parts with minimal undercuts. If your part features intricate geometries, undercuts, or requires multiple gating points, a 3-plate mold may be the better choice.

Gating Requirements and Cosmetic Considerations

Consider where you need to place the gate on your part. 2-plate molds typically have a single gating point, which can limit design flexibility and may lead to cosmetic defects. 3-plate molds offer more freedom in gate placement, allowing for strategic positioning to minimize visual imperfections.

Production Volume and Budget

Your production volume and budget also influence mold selection. 2-plate molds are generally more cost-effective for high-volume production of simple parts. They have a lower initial investment and shorter cycle times. 3-plate molds, while more expensive, are valuable for producing complex parts in lower volumes.

Material Properties and Molding Requirements

The material you plan to use and its specific molding requirements should also be taken into account. Some materials may require higher injection pressures or longer cooling times, which can impact mold selection. Discuss your material choice with your injection molding partner to determine the most suitable mold type.

| Factor | 2-Plate Mold | 3-Plate Mold |

| Part Complexity | Simple, flat parts | Complex geometries, undercuts |

| Gating | Single gating point | Multiple gating points |

| Production Volume | High-volume, simple parts | Low-volume, complex parts |

| Budget | Lower initial investment | Higher initial investment |

| Material Properties | Discuss with molding partner | Discuss with molding partner |

Summary

In summary, 2-plate molds are simpler, cost less, and have faster cycle times, while 3-plate molds offer more flexibility and better surface quality. Choosing between them depends on your part's design, production volume, and budget. It's important to balance these factors to ensure efficiency and cost-effectiveness. For complex decisions, consulting with injection molding experts can provide valuable insights and tailored recommendations. This helps ensure you choose the right mold for your specific manufacturing needs.