Injection molding is a critical manufacturing process. But what happens when it goes wrong? Flash, a common defect, occurs when molten plastic escapes the mold, creating excess material. This flaw can damage molds and reduce part quality. In this post, you'll learn about the causes of flash, effective solutions, and how to prevent it.

What is Injection Molding Flash?

Injection molding flash, also known as flashing, is a common defect that plagues plastic parts. It's an annoying imperfection that rears its ugly head in the form of a thin, extra layer of plastic. This pesky excess material usually shows up along the part's edges or seams.

So, what does this flashing look like? Well, it often resembles a thin, wavy plastic film or fringe. You might spot it jutting out from the part's surface, ruining that smooth, pristine look you were going for.

Picture this: you've got a freshly molded plastic component in your hands. As you run your fingers along its surface, you suddenly feel a rough, jagged edge. That, my friend, is likely a flash. It's an unwanted guest at the injection molding party.

Now, flashing isn't just an eyesore. It can cause some serious headaches down the line. For starters, it can compromise the part's aesthetics. Nobody wants a product that looks sloppy or unfinished, right?

But the problems don't stop there. Flash can also interfere with the part's functionality. Imagine trying to snap two components together, but the flash gets in the way, preventing a proper fit. Talk about frustrating!

And let's not forget the financial impact. Dealing with flash often means extra time and money spent on secondary operations like trimming and finishing. It's a costly inconvenience that can eat into your bottom line.

In short, injection molding flash is:

A thin, excess layer of plastic

Often found along part edges or seams

A cosmetic and functional nuisance

A potential drain on time and resources

So, there you have it - the lowdown on injection molding flash. It's a pesky problem that can really put a damper on your molding mojo. But fear not! In the coming sections, we'll dive into the causes and solutions to help you kick flash to the curb.

Common Causes of Flash in Injection Molding

Flash, that pesky little defect that loves to crash the injection molding party. But what exactly causes this unwanted guest to show up? Let's dive in and explore the common culprits behind flashing.

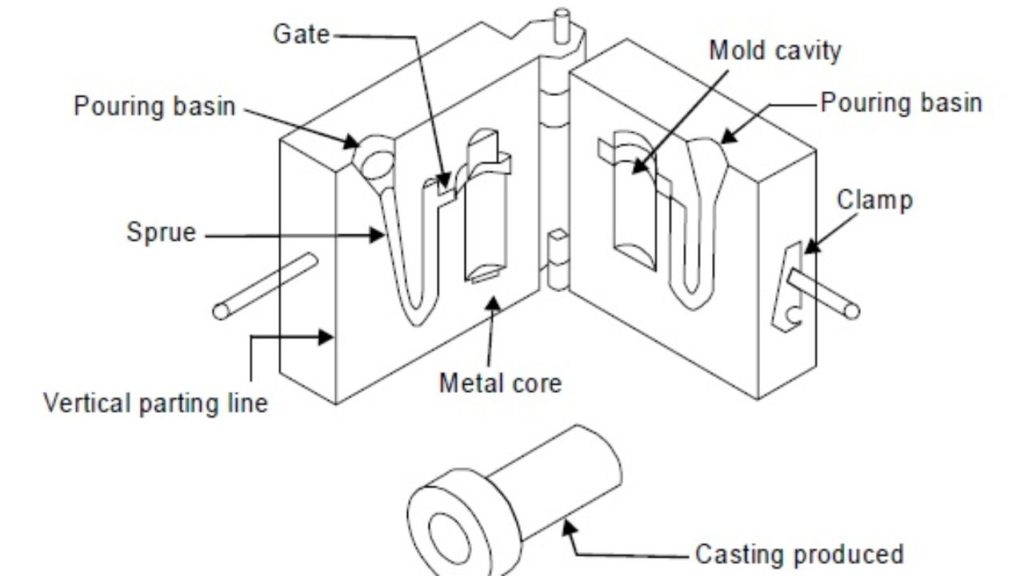

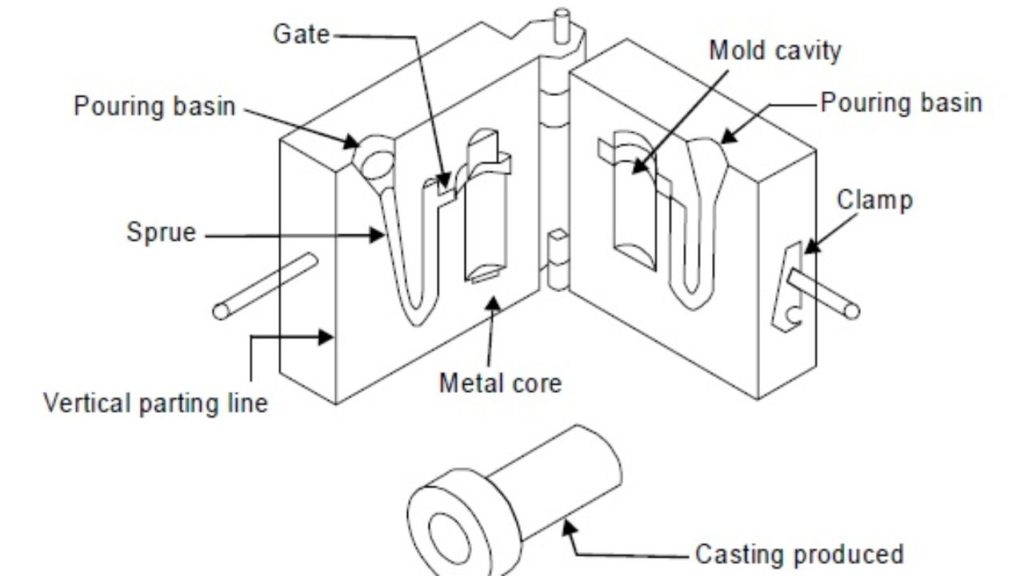

Parting Line Mismatches

One of the biggest reasons for flash is when the mold halves don't fit together like they should. It's like trying to close an overstuffed suitcase - there's bound to be some spillage.

Dirt and debris can prevent the mold from closing completely, leaving gaps for the molten plastic to seep through. It's a real buzzkill!

Worn-out mold cavities are another issue. Over time, the constant wear and tear can cause the mold to lose its snug fit, creating space for flash to form. It's like trying to button a shirt that's seen too many washes.

Complex part geometries can also complicate mold closure. All those intricate nooks and crannies can make it harder for the mold to seal properly, leading to - you guessed it - flash.

Improper Venting

Vents are like the escape routes for trapped air and gases in the mold. But when these vents aren't up to snuff, trouble ensues.

If the vents are too shallow for the plastic's viscosity, it's like trying to drain a thick milkshake through a tiny straw. The result? Pressure builds up, forcing the plastic out and creating flash.

Aged or damaged vents that don't meet the proper tolerances can also cause problems. It's like having a clogged drain - the air and gases have nowhere to go, leading to flashing.

Low Clamping Pressure

Clamping pressure is the force that holds the mold together during injection. But when this pressure is too low, it's like trying to keep a lid on a boiling pot with a feather.

If the injection pressure overpowers the clamp force, the mold can slightly open, allowing the plastic to escape and form flash. It's a real pressure cooker situation!

This can also happen during the packing and holding stages. If the mold parting line separates due to insufficient clamping, flash can rear its ugly head.

Low Viscosity and Uneven Flow

The viscosity of the molten plastic plays a big role in flashing. If the melt temperature is too high, the plastic becomes more fluid and prone to leaking. It's like trying to contain water with a pasta strainer.

Long residence times can cause the plastic to degrade, altering its viscosity. It's like leaving a sauce on the stove for too long - it just doesn't flow right anymore.

Insufficient drying can leave moisture in the plastic, which can also affect its viscosity and lead to uneven flow. It's like trying to mix oil and water - it just doesn't work well.

Excess colorants with lubricating effects can also contribute to low viscosity and flashing. It's like adding too much oil to a recipe - things get slippery!

Overfilling the Mold

Overfilling the mold is like trying to stuff too much jelly into a donut. When the injection pressure exceeds the clamp pressure, the excess plastic has to go somewhere. And that somewhere is often in the form of flash.

The extra material can attach itself to the part, creating unsightly flash. It's like getting a blob of jelly on your shirt - it's not a good look.

Solutions for Injection Molding Flash

So, you've got a case of the flashes. Don't worry, it happens to the best of us! Let's explore some solutions to help you get rid of that pesky excess plastic.

Using Hot Air

Hot air can be your friend when it comes to fixing thin flashes. It's like using a hairdryer to smooth out a wrinkle in your clothes.

By applying targeted heat, you can melt those thin bits of flash back into the part. It's a quick and easy fix for minor flashing issues.

However, hot air has its limits. It's not the best choice for thicker or more stubborn flashes. Think of it like trying to use a hairdryer to dry a thick wool sweater - it's just not going to cut it.

Cryogenic Deflashing

If you want to get fancy, cryogenic deflashing might be the way to go. It's like giving your parts a super-cool spa treatment.

The process involves exposing the flashed parts to extremely low temperatures, usually using liquid nitrogen. This makes the flash brittle and easier to remove.

Cryogenic deflashing can be effective, but it does require specialized equipment. It's like needing a fancy cryo-chamber for that spa treatment.

Manual Deflashing

Sometimes, the old-fashioned way is the best way. Manual deflashing involves using tools like knives, scrapers, or abrasive pads to physically remove the flash.

It's like trimming the crust off a slice of bread. You've got to have a steady hand and a keen eye for detail.

Manual deflashing gives you a lot of control and can work on various types of flashes. But it can be time-consuming, especially for larger parts or high volumes.

It's like hand-stitching a quilt - it's a labor of love.

Using Open Flame

If you're feeling a bit adventurous, you might consider using an open flame to remove flash. It's like taking a blowtorch to your parts!

The heat from the flame can melt away the excess plastic, leaving you with a cleaner part. But be careful - it's not for the faint of heart.

Using an open flame comes with some risks. It's like playing with fire...literally. You've got to be cautious not to damage the part or cause any safety hazards.

It's also not the most precise method. It's like using a flamethrower to light a candle - there's a chance of overdoing it.

Here's a quick summary of the pros and cons of each method:

| Method | Pros | Cons |

| Hot Air | Quick and easy for thin flashes | Not effective for thicker flashes |

| Cryogenic Deflashing | Effective for removing flash | Requires specialized equipment |

| Manual Deflashing | Gives control and works on various flashes | Time-consuming, especially for high volumes |

| Open Flame | Can melt away excess plastic | Risky, imprecise, and can damage parts |

So, there you have it - a rundown of some solutions for injection molding flash. Whether you opt for hot air, cryogenic treatment, manual removal, or an open flame, there's a method out there for you.

Just remember, prevention is always better than a cure. Stay tuned for tips on how to avoid flash in the first place!

How to Prevent Flash in Injection Molding

They say an ounce of prevention is worth a pound of cure. The same goes for injection molding flash. Instead of dealing with the headache of removing it later, why not stop it from happening in the first place? Here's how you can prevent flash and keep your parts looking pristine.

Design for Manufacturability (DFM)

DFM is like the secret weapon against flash. It's all about designing your parts with the manufacturing process in mind.

Optimizing your design for simple mold parting lines is a great start. Think of it like creating a jigsaw puzzle - you want the pieces to fit together seamlessly.

Using DFM software is like having a crystal ball. It can simulate the injection molding process and help you spot potential issues before they become real problems. It's like having a sneak peek into the future!

Use a Flash-Free Mold

If you want the crème de la crème of flash prevention, consider using a flash-free mold. It's like having a superhero mold that fights off flash with its mighty powers.

Flash-free molds are designed with extra precision and tight tolerances. They're like the luxury cars of the molding world - sleek, refined, and leaving no room for imperfections.

Apply Proper Clamp Tonnage

Clamping is like giving your mold a big bear hug. You want it to be snug and secure, but not so tight that it causes damage.

Applying the right amount of clamp tonnage is crucial. Too little, and you might get flash. Too much, and you could harm the mold. It's a delicate balance, like Goldilocks finding the perfect porridge.

Slow Down the Injection Rate

Sometimes, slow and steady wins the race. Slowing down the injection rate can help reduce pressure and minimize the risk of flash.

It's like pouring a glass of soda - if you do it too fast, it'll fizz and overflow. But if you take it slow, you can keep things under control.

Ensure Thorough Mold Cleaning and Maintenance

A clean mold is a happy mold. Regularly removing contaminants and debris helps ensure that the mold can close fully and avoid flash.

It's like keeping your room tidy - if there's stuff in the way, the door won't close properly.

If your vents are worn out, re-machining them to the proper specifications can work wonders. It's like giving your mold a fresh set of lungs to breathe easy.

Adjust Process Variables

Fine-tuning your process variables is like finding the perfect recipe for flash-free parts. Here are some key ingredients to tweak:

Reduce injection and packing pressure to avoid overpowering the mold

Lower barrel and nozzle temperatures to maintain the right material viscosity

Correct metering to prevent overfilling and excess material

Choose a material with the optimal viscosity for your part design

By adjusting these variables, you can create the ideal conditions for a flash-free result. It's like conducting a symphony of injection molding perfection!

| Variable | Adjustment |

| Injection Pressure | Reduce to avoid overpowering the mold |

| Packing Pressure | Decrease to minimize flash risk |

| Barrel Temperature | Lower to maintain proper viscosity |

| Nozzle Temperature | Reduce to control material flow |

| Metering | Correct to prevent overfilling |

| Material Viscosity | Choose optimal for part design |

So, there you have it - your guide to preventing injection molding flash. By designing for manufacturability, using flash-free molds, applying proper clamp tonnage, slowing down the injection rate, keeping your mold clean and well-maintained, and adjusting process variables, you can say goodbye to flash and hello to picture-perfect parts.

Other Common Injection Molding Defects

Flash isn't the only troublemaker in the world of injection molding. There's a whole gang of defects that can rear their ugly heads and wreak havoc on your parts. Let's take a look at some of these common culprits.

Sink Marks

Sink marks are like little dimples or craters on your part's surface. They form when thicker areas cool unevenly, causing the material to shrink more in those spots. It's like when you leave a dent in your memory foam pillow.

Discoloration

Discoloration is when your part comes out looking a bit...off. Improper mixing of colors or contamination can cause this unsightly issue. It's like accidentally mixing a red sock with your white laundry - pink parts, anyone?

Weld Lines

Weld lines appear when two flow fronts meet but don't quite fuse together completely. It's like when you try to glue two pieces of paper together, but there's still a visible seam. Not the seamless look you were going for!

Burn Marks

Burn marks are those unsightly dark spots that can appear on your part. They happen when the material gets too hot or when air gets trapped during molding. It's like leaving your toast in for too long - burnt and bitter!

Short Shots

Short shots happen when the mold doesn't fill completely, leaving you with an incomplete part. It's like when you're filling up a glass of water, but you stop before it's full. No one likes a half-filled part!

Vacuum Voids

Vacuum voids are like tiny air bubbles trapped inside your part. They occur when the part cools unevenly, causing pockets of emptiness. It's like biting into a chocolate chip cookie and realizing the chips are missing!

Warping

Warping is when your part comes out looking like it took a trip through the funhouse mirror. Different areas of the part shrink at different rates, causing it to bend and distort. It's like leaving a plastic container too close to the stove - all twisted and warped!

Surface Delamination

Surface delamination is when a thin layer of the part's surface peels or flakes off. Foreign materials or contaminants can cause this unsightly issue. It's like when you peel off a sticker, and it leaves a residue behind - not a good look!

Jetting

Jetting happens when the molten plastic is injected too fast and doesn't adhere properly to the mold. It creates a streak or a squirt-like pattern on the part's surface. It's like when you squeeze a ketchup bottle too hard, and it shoots out in a stream!

Flow Lines

Flow lines are those wavy or streaky patterns that can appear on your part. They happen when the material cools at inconsistent rates as it flows through the mold. It's like when you pour cream into your coffee, and it creates swirly patterns - but not as appetizing on your plastic part!

| Defect | Cause |

| Sink Marks | Thick areas cooling unevenly |

| Discoloration | Improper mixing or contamination |

| Weld Lines | Two flow fronts not fusing completely |

| Burn Marks | Overheating or trapped air |

| Short Shots | Incomplete mold filling |

| Vacuum Voids | Uneven part cooling creating air pockets |

| Warping | Variable shrinkage in different areas |

| Surface Delamination | Foreign material causing surface to peel |

| Jetting | Fast injection not binding to mold |

| Flow Lines | Inconsistent cooling rates creating streaky patterns |

Conclusion

Flash is a widespread but preventable molding defect. It can stem from mold, material, or process issues. While flash can be fixed after it occurs, it's best to avoid it entirely.

Ensuring attention to part and mold design, along with careful processing, is crucial. Partnering with an experienced molder is highly recommended to achieve the best results. By doing so, you can minimize defects and enhance product quality.

Got more questions about injection molding? Reach out to Team Mfg for expert advice and top-notch molding services to bring your project to life. Our experienced team is ready to assist you every step of the way.