Polyphthalamide (PPA) is a game-changer in engineering plastics. Have you ever wondered what makes high-performance plastics so crucial in industries? PPA is a semi-crystalline, aromatic polyamide that offers superior strength and heat resistance.

In this post, you'll learn unique properties, applications, manufacturing considerations, modifications and comparisons with other engineering plastics of PPA plastic, providing valuable insights for designers and manufacturers.

What is Polyphthalamide (PPA)?

PPA, or polyphthalamide, is a high-performance plastic material. It belongs to the family of semi-crystalline aromatic polyamides.

PPA is known for its exceptional properties, including:

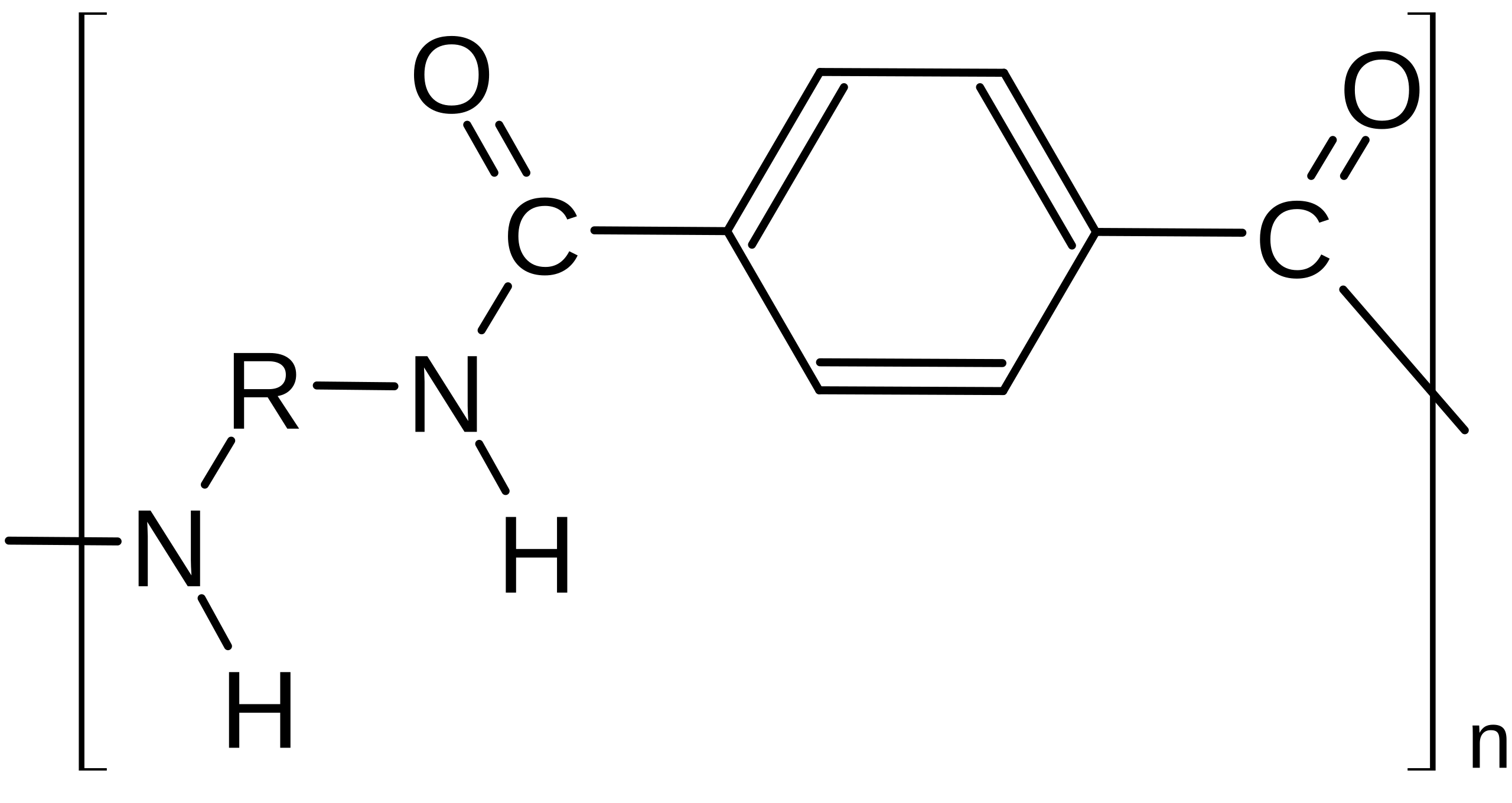

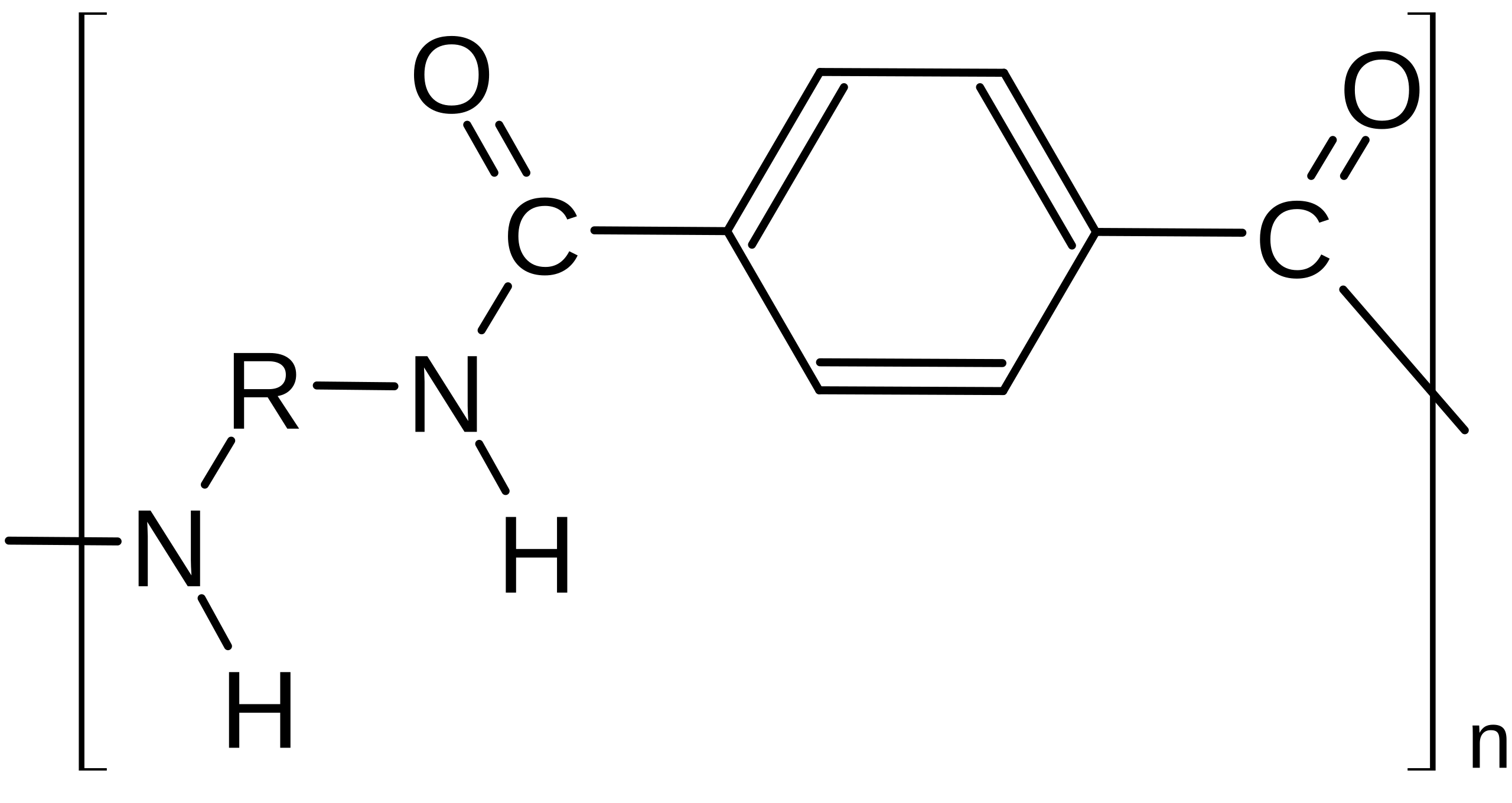

Chemical Composition and Structure

The chemical structure of PPA consists of aromatic rings and amide groups. These groups are alternately bonded to aliphatic groups and benzenedicarboxylic acid groups.

PPA's CAS number, which is a unique identifier, is 27135-32-6.

Properties of PPA

| Property | Value |

| Melting Point | High (>150°C) |

| Glass Transition Temperature | High (>150°C) |

| Heat Distortion Temperature | >280°C |

| Tensile Strength | High |

| Stiffness | High |

| Notched Impact Strength | Higher than comparable plastics |

| Friction Coefficient | Low |

| Abrasion Coefficient | Low |

| Creep Tendency | Low |

| Moisture Absorption | Very low (0.1-0.3%) |

| Chemical Resistance | Very high, even to aggressive chemicals |

| Thermal Resistance | High |

| Electric Resistance | High |

| Resistance to Wear | High |

| Surface Resistance | Very high |

| Volume Resistance | Very high |

| Tracking Resistance | High, hardly impaired by moisture content |

| Fatigue Resistance | Excellent |

| Dimensional Stability | Excellent, low warpage |

| Crystallinity | Contributes to chemical resistance and excellent mechanical properties |

| Corrosion Resistance | Excellent |

| Adhesion to Elastomers | Direct, without need for bonding agents |

| Flammability | Not inherently flame retardant |

| Processing Temperature | High (up to 350°C) |

Comparison with Other Engineering Plastics

Polyphthalamide (PPA) stands out among engineering plastics due to its impressive balance of mechanical, thermal, and chemical properties. Here's how PPA compares to other commonly used engineering plastics.

PPA vs. Nylon 6/6

Compared to Nylon 6/6, PPA offers superior strength and stiffness, making it better suited for high-performance applications. Additionally, PPA has much higher heat resistance, allowing it to maintain structural integrity at elevated temperatures where Nylon 6/6 would soften or deform.

| Property | PPA | Nylon 6/6 |

| Strength | Higher | Lower |

| Stiffness | Superior | Less stiff |

| Heat Resistance | Higher (up to 280°C) | Moderate (up to ~180°C) |

PPA vs. PA46

When compared to PA46, PPA exhibits higher thermal stability. This makes PPA a better choice in applications involving prolonged exposure to high temperatures. However, both PPA and PA46 offer similar levels of chemical resistance, allowing them to perform well in chemically aggressive environments.

| Property | PPA | PA46 |

| Thermal Stability | Higher | High |

| Chemical Resistance | Similar | Similar |

PPA vs. PA6

PPA outperforms PA6 in terms of mechanical properties, offering greater strength, stiffness, and durability. However, PPA requires higher processing temperatures, which can increase the complexity and cost of manufacturing compared to PA6.

| Property | PPA | PA6 |

| Mechanical Properties | Superior | Lower |

| Processing Temperature | Higher (~350°C) | Lower (~260°C) |

Modifications of PPA

Polyphthalamide (PPA) can be tailored to meet specific performance needs through various modifications. These enhancements make it even more versatile in demanding applications.

Reinforcement with Fillers

PPA can be reinforced with glass or mineral fillers to boost its mechanical properties. These fillers significantly improve stiffness, strength, and resistance to wear and tear. Applications that benefit from this include thermostat housings and pump wear rings, where durability is key.

Impact Modifiers

Adding elastomers to PPA increases its toughness, making it more resilient to impact. This modification is especially useful for automotive crash components, where safety is critical. Electronic device housings also benefit, as they need to withstand accidental drops and shocks.

Increased toughness: Ensures durability under dynamic loads

Applications: Automotive crash parts, electronic housings

Heat Stabilizers

Heat stabilizers are added to allow PPA to withstand prolonged exposure to high temperatures without degradation. This modification is essential for automotive and industrial components that operate in hot environments, like under-the-hood car parts or machinery in industrial processes.

Flame Retardants

Flame retardants are critical for applications where fire safety is a top priority. These additives ensure that PPA materials meet stringent safety standards, making them suitable for use in electronics, automotive, and construction materials.

Improved fire safety: Limits combustion and smoke emission

Applications: Electronics, automotive parts, building materials

Compounding PPA with Other Plastics

PPA can be compounded with other plastics to enhance its properties. This expands its range of applications.

PPA Compounded with Polyphenylene Sulfide (PPS)

When PPA is combined with Polyphenylene Sulfide (PPS), the result is a material with high strength and stiffness. This blend also offers excellent chemical and heat resistance, making it perfect for harsh environments where durability is essential.

PPA Compounded with Nylon

Blending PPA with Nylon enhances toughness and impact resistance while maintaining good dimensional stability. This combination is ideal for applications that need to balance durability and ease of processing.

Toughness and impact resistance: Increased durability in high-stress environments

Dimensional stability: Maintains shape and performance during use

Processability: Easier to mold and form, making it more versatile

PPA Compounded with Polyethylene Terephthalate (PET)

When PPA is compounded with Polyethylene Terephthalate (PET), the blend combines excellent heat resistance, mechanical strength, and dimensional stability. Additionally, it offers strong chemical resistance, making it ideal for applications requiring both durability and precision.

Heat resistance: Withstands high temperatures without degradation

Mechanical strength: Strong and durable, suitable for structural components

Dimensional stability and chemical resistance: Reliable in chemically aggressive environments

Applications of PPA

Polyphthalamide (PPA) excels in a variety of industries due to its exceptional thermal, mechanical, and chemical properties.

Automotive Industry

PPA is widely used in the automotive sector, particularly in high-temperature and chemically demanding environments.

Fuel line connectors: PPA's heat resistance and chemical stability make it ideal for fuel delivery systems.

Thermostat housings: It maintains mechanical integrity even at elevated temperatures, ensuring reliable engine cooling.

Air coolant pumps: PPA's durability and performance allow it to function under demanding conditions.

| Automotive Application | Benefit |

| Fuel line connectors | Heat and chemical resistance |

| Thermostat housings | Maintains structure at high temps |

| Air coolant pumps | Durable under tough conditions |

Electronics Industry

PPA's thermal and electrical properties make it a perfect material for electronic components requiring high durability.

LED mounts: It handles the heat generated by LEDs while providing strong structural support.

Wire and cable protection: PPA offers insulation and protection from environmental factors, ensuring long-term reliability.

Connectors: It remains reliable in high-temperature environments, crucial for electronic devices.

| Electronics Application | Benefit |

| LED mounts | Excellent thermal management |

| Wire and cable protection | Insulation and environmental safety |

| Connectors | Stability in high-temp conditions |

Industrial Applications

In industrial environments, PPA shines with its wear resistance and stability under harsh conditions.

Pump wear rings: Its abrasion resistance and dimensional stability ensure smooth operation over time.

Mechanical components: Bearings, gears, and bushings made from PPA deliver high mechanical strength and wear resistance.

Chemical-resistant parts: PPA's chemical resistance makes it suitable for harsh environments like chemical processing plants.

| Industrial Application | Benefit |

| Pump wear rings | Abrasion resistance, stability |

| Mechanical components | Strength and wear resistance |

| Chemical-resistant parts | Withstands harsh chemical exposure |

Consumer Goods

PPA is also present in everyday consumer products, providing durability and performance.

Toothbrush and hairbrush bristles: PPA's durability and resistance to chemicals ensure long-lasting performance in personal care products.

Appliance components: It’s used in heat-resistant parts for dishwashers and ovens, enhancing product longevity.

Personal care items: Razor handles and cosmetic packaging benefit from PPA's durability and aesthetic appeal.

| Consumer Goods Application | Benefit |

| Toothbrush/hairbrush bristles | Chemical resistance, durability |

| Appliance components | Heat resistance for household items |

| Personal care items | Strength and aesthetic appeal |

Processing Techniques

Processing PPA requires specialized techniques. Its unique properties demand careful handling.

Injection Molding

Injection molding is the primary method for processing PPA. The material's high melting point necessitates elevated temperatures.

Typical processing temperatures for PPA can reach up to 350°C (662°F). These high temperatures ensure proper melt flow and mold filling.

However, PPA's high melt viscosity presents challenges. It can make mold filling difficult.

Careful control of processing parameters is essential. Temperature, pressure, and injection speed must be optimized.

| Parameter | Typical Value |

| Melt Temperature | 330-350°C |

| Mold Temperature | 140-180°C |

| Injection Pressure | 100-150 MPa |

| Injection Speed | Moderate |

Specialized equipment may be necessary. High-temperature resistant molds and barrels are often required.

Machining and Surface Finishing

PPA can be machined using standard techniques. However, its high strength and heat resistance pose challenges.

Tools must withstand the high temperatures generated during machining. Carbide tools are often used for their durability.

Proper cooling methods are crucial. They prevent overheating and maintain tool life.

| Machining Operation | Recommended Tools |

| Turning | Carbide inserts |

| Milling | Carbide end mills |

| Drilling | Carbide drills |

Post-molding processes are often employed. They help achieve desired surface finishes and properties.

Polishing can improve surface smoothness. It enhances aesthetic appeal.

Annealing relieves internal stresses. It improves dimensional stability.

Abrasive blasting can create matte or textured finishes. It offers design flexibility.

Assembly Techniques

PPA components can be assembled using various methods. The choice depends on the application and design requirements.

Welding is a common technique for joining PPA parts. Ultrasonic and laser welding are often used.

Screwing and riveting are also viable options. They provide strong, mechanical connections.

Other assembly methods include snap-fitting and adhesive bonding. They offer design flexibility and simplicity.

| Assembly Method | Advantages |

| Welding | Strong, permanent joints |

| Screwing | Removable, mechanical connection |

| Riveting | Simple, strong mechanical fastening |

| Snap-fitting | Quick, easy assembly |

| Adhesive bonding | Versatile, joins dissimilar materials |

The choice of assembly technique depends on various factors. Material compatibility, strength requirements, and production efficiency are key considerations.

Design Considerations for PPA Components

Designing with PPA requires careful consideration. Various factors influence the performance and manufacturability of PPA components.

Structural Design Optimization

Proper structural design is crucial for PPA parts. It ensures optimal performance and longevity.

Thickness transitions should be gradual. Abrupt changes can lead to stress concentration.

Ribbing and boss design can improve rigidity and strength. They should be appropriately sized and placed.

Shrinkage and warpage must be controlled. Different shapes and sizes may require specific design adjustments.

Draft angles and radius transitions facilitate demolding. They should be adequate for the part geometry.

| Design Element | Recommendation |

| Thickness transitions | Gradual, avoid abrupt changes |

| Ribbing and bosses | Appropriately sized and placed |

| Shrinkage and warpage | Control for different shapes and sizes |

| Draft angles | Adequate for easy demolding |

| Radius transitions | Sufficient for part geometry |

Heat Management and Thermal Dissipation

PPA components may generate or be exposed to heat. Proper heat management is essential.

Cooling channels can help dissipate heat. They should be strategically placed.

Thermal expansion should be considered. It can affect part dimensions and fit.

Material Selection and Additives

The choice of PPA grade and additives is crucial. It depends on the specific application requirements.

Reinforcements like glass fibers or minerals can enhance properties. They improve strength, stiffness, and dimensional stability.

Additives can impart specific properties. Lubrication, UV stability, and flame retardancy are common examples.

| Additive | Property Enhancement |

| Lubricants | Improved flow and mold release |

| UV stabilizers | Resistance to UV degradation |

| Flame retardants | Reduced flammability |

Dimensional Stability and Moisture Absorption

PPA has low moisture absorption. However, designing for minimal moisture sensitivity is still important.

Proper sealing and protective coatings can further reduce moisture intake. They help maintain dimensional stability.

Manufacturability and Processing Considerations

Designing for manufacturability is key. It ensures efficient and cost-effective production.

Draft angles and fillets facilitate molding and demolding. They should be incorporated into the design.

Tooling design should account for PPA's high processing temperatures. Proper cooling and venting are essential.

Machining and Surface Finishing Techniques

PPA components may require machining and surface finishing. The choice of techniques depends on the desired outcome.

Machining parameters should be optimized for PPA. Proper tool selection and cooling are crucial.

Surface finishing techniques like polishing or abrasive blasting can enhance aesthetics. They can also improve functional properties.

Designing with PPA requires a holistic approach. Structural integrity, heat management, material selection, and manufacturability are all important.

Conclusion

In conclusion, PPA plastic stands out for its superior thermal, mechanical, and chemical properties. Its high heat resistance and strength make it ideal for demanding applications. PPA’s versatility shines across industries like automotive, electronics, industrial, and consumer goods. Its ability to perform under tough conditions makes it a reliable choice for many products.

Tips: You maybe interested to the all plastics