Plastic moulding processes convert molten plastic materials into solid products with predetermined shapes and properties. This manufacturing technique employs various methods to create custom plastic moulded components. The six primary molding technologies - extrusion molding, compression molding, blow molding, rotational molding, injection moulding, and thermoforming. - dominate industrial plastic processing.

Each method brings distinct advantages and capabilities to molding plastic manufacturing. From high-volume production of precise components to large-scale hollow products, these processes serve diverse industrial needs. Selection of the appropriate moulding technique depends on factors including product design, material requirements, production volume, and economic considerations.

1. Blow Molding

Benefits of Blow Molding

High-volume production of hollow parts at low cost

Creates uniform wall thickness across complex container shapes

Multiple cavity molds enable rapid production of bottles

Key Applications

Plastic bottles from small medical to large containers

Automotive fuel tanks with complex internal baffling systems

Industrial chemical containers requiring precise material specifications

The blow molding process begins with creating a parison - a hollow tube of heated plastic that emerges from an extruder. This parison is positioned between two mold halves, which close around it. Compressed air is then introduced through a blow pin, inflating the soft plastic until it conforms to the mold's internal shape. Once cooled against the chilled mold walls, the solid part is ejected.

Blow molding excels at producing hollow plastic products efficiently and economically, particularly for high-volume production. The process creates seamless, uniform containers ranging from small medical bottles to large industrial drums. Its ability to form complex shapes with integrated handles and special features makes it ideal for consumer packaging and automotive fuel tanks.

The molding process primarily utilizes thermoplastic materials that offer good melt strength and viscosity control. Common materials include high and low-density polyethylene (HDPE/LDPE) for household containers, polyethylene terephthalate (PET) for beverage bottles, and polypropylene (PP) for chemical-resistant containers. Material selection depends on specific requirements for clarity, strength, and chemical resistance.

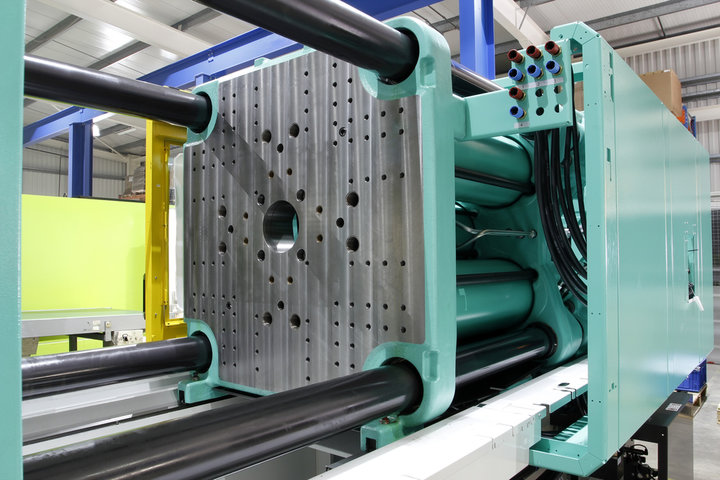

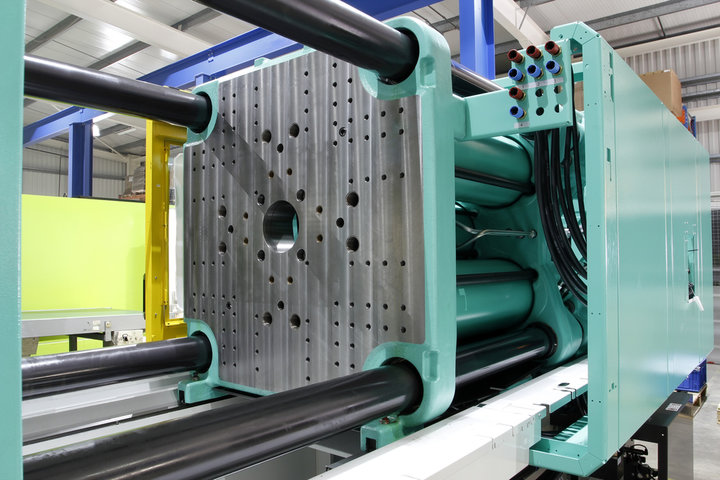

2. Injection Molding

Benefits of Injection Molding

Produces complex plastic parts with tight dimensional accuracy

High production rates through automated multi-cavity mold systems

Excellent surface finish with minimal post-processing requirements

Key Applications

Electronic housings requiring precise fits and multiple features

Medical components meeting strict regulatory and quality standards

Automotive parts demanding high strength and aesthetic qualities

Injection molding operates by forcing molten plastic into a closed mold cavity under high pressure. The process starts as plastic pellets feed into a heated barrel containing a rotating screw. As the screw turns, it melts and homogenizes the material while building up pressure. When sufficient material has accumulated, the screw acts as a plunger, rapidly injecting the molten plastic into the mold.

This versatile process dominates plastic manufacturing due to its ability to produce complex parts with excellent dimensional accuracy and surface finish. It's particularly efficient for high-volume production of components ranging from tiny medical devices to large automotive panels. The process allows for intricate details, multiple cavities, and automated part removal.

Material options for injection molding span nearly the entire range of thermoplastics. Common choices include ABS for durable consumer goods, polypropylene for living hinges and consumer packaging, nylon for engineering components, and polycarbonate for transparent and impact-resistant parts. Additives can enhance properties like strength, flame resistance, or UV stability.

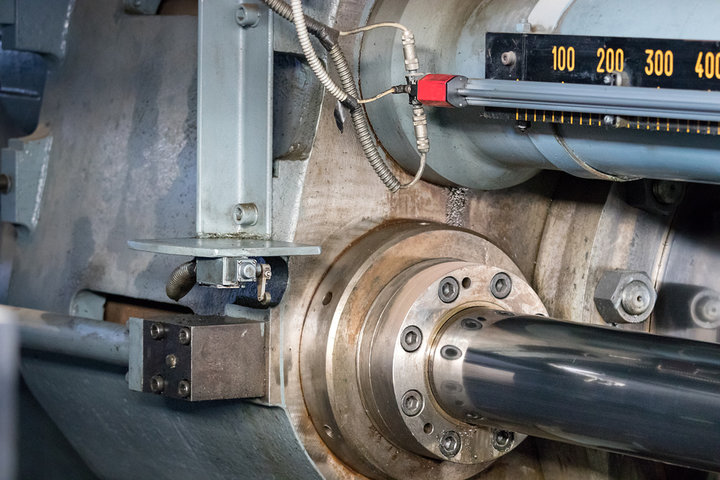

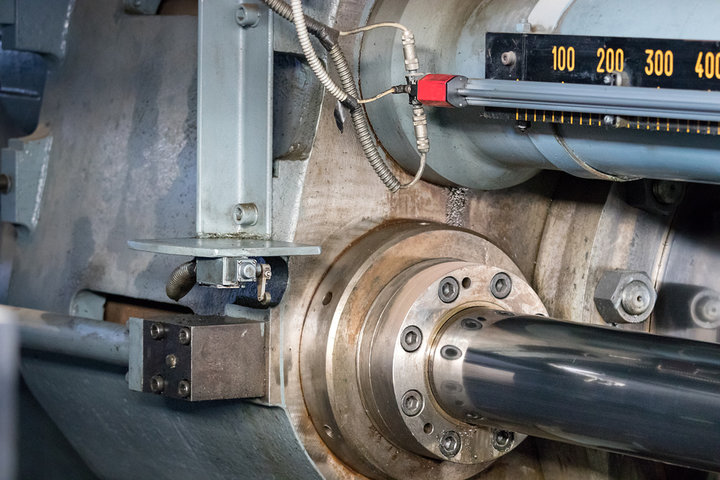

3. Extrusion Molding

Benefits of Extrusion Molding

Continuous production creates consistent profiles at high volume

Multiple materials can combine in single production run

Simple process control enables efficient long-term production cycles

Key Applications

Pipes and tubes for construction and industrial use

Window frames with multiple chambers for thermal efficiency

Wire coating for electrical and communication cable systems

Extrusion molding is a continuous process where plastic material is forced through a shaped die to create products with consistent cross-sections. Raw plastic pellets feed into a heated barrel containing a rotating screw that melts, mixes, and pressurizes the material. As the screw turns, it pushes the molten plastic through a die that shapes the material into its final profile configuration.

The continuous nature of extrusion makes it ideal for producing long-length products efficiently. Common applications include pipes, tubing, window frames, wire coatings, and plastic sheets or films. The process can also create complex profiles with multiple channels or hollow sections, making it valuable for construction and industrial applications.

Material selection for extrusion typically focuses on thermoplastics with good melt flow characteristics. PVC dominates pipe and profile applications due to its durability and weather resistance. Polyethylene is common in film and packaging applications, while specialized materials like fluoropolymers are used for high-performance wire coatings.

4. Compression Molding

Benefits of Compression Molding

Forms large structural parts with fiber reinforcement options

Produces thick sections with minimal internal stress issues

Material waste reduction through precise charge weight control

Key Applications

Automotive panels requiring high strength and surface finish

Industrial components with demanding structural performance requirements

Electrical housings needing specific insulation and heat properties

Compression molding involves placing a measured amount of plastic material into a heated mold cavity. The material, typically a thermoset in powder or preform form, is compressed between heated mold halves under high pressure. Heat and pressure cause the material to flow throughout the cavity while initiating a chemical curing reaction that permanently sets the plastic's shape.

This process particularly suits manufacturing large, structurally robust parts that require excellent strength and dimensional stability. Common applications include automotive body panels, electrical components, and heavy-duty industrial parts. The ability to incorporate reinforcing materials like glass fibers makes it valuable for producing high-strength composite components.

Thermoset materials dominate compression molding due to their unique curing properties. Bulk molding compounds (BMC) and sheet molding compounds (SMC) are widely used, combining polyester or epoxy resins with reinforcing fibers. Phenolic resins are chosen for high-temperature applications, while melamine compounds are common in dinnerware.

5. Rotational Molding

Benefits of Rotational Molding

Creates stress-free hollow parts with uniform wall thickness

Multiple parts production in single machine cycle

Design flexibility allows complex shapes without weld lines

Key Applications

Large storage tanks for industrial and agricultural use

Durable playground equipment with complex curved surfaces

Material handling containers with integrated structural features

Rotational molding begins with loading plastic powder into a hollow mold that rotates biaxially in a heated chamber. As the mold rotates, the powder melts and coats the interior surfaces uniformly. Continuous rotation during the cooling phase ensures even wall thickness distribution. The completed part is removed once fully cooled.

This unique process excels at producing large, hollow parts with uniform wall thickness and no internal stresses. It's particularly suited for manufacturing storage tanks, industrial containers, playground equipment, and kayaks. The process allows for complex shapes with integrated features and offers design freedom for large-scale hollow products.

Polyethylene dominates rotational molding due to its wide processing window and excellent stability during heating. Linear low-density polyethylene (LLDPE) is preferred for flexibility and impact resistance, while cross-linked polyethylene provides enhanced strength and temperature resistance. PVC plastisols and nylon are also used for specialized applications.

6. Thermoforming

Benefits of Thermoforming

Rapid production cycles for large surface area parts

Low-cost tooling enables economical short production runs

Simple process allows quick design changes and prototypes

Key Applications

Food packaging requiring consistent depth and wall thickness

Vehicle panels with specific surface texture requirements

Retail displays featuring complex curves and brand details

Thermoforming starts by heating a plastic sheet until it becomes pliable. The softened sheet is then formed against or into a mold using vacuum pressure, compressed air, or mechanical force. The plastic cools in contact with the mold surface, retaining the desired shape. Advanced variations include twin-sheet forming and pressure forming for more complex geometries.

This versatile process is particularly effective for producing large, thin-walled parts with relatively simple geometries. Common applications include packaging trays, food containers, refrigerator liners, and vehicle dashboards. The relatively low tooling costs make it attractive for both prototype development and production runs of varying sizes.

Material selection focuses on thermoplastic sheets with good forming characteristics. High-impact polystyrene (HIPS) is popular for packaging applications, while acrylic provides clarity for displays and lighting covers. ABS offers durability for equipment housings, and specialized materials like PEEK are used for high-temperature applications in aerospace and medical sectors.

How to Choose Right Plastic Molding Technology

Production Volume Considerations

High volume (100,000+) benefits from injection molding automation

Medium runs (1,000-10,000) suit thermoforming or blow molding

Low volume prototypes work best with rotational molding

Part Design Factors

Complex geometries and tight tolerances require injection molding

Hollow containers are best suited for blow molding

Large panels with simple shapes favor thermoforming methods

Material Selection Guidelines

Engineering plastics perform best in injection molding processes

Polyethylene and PET excel in blow molding applications

Thermoset materials require compression molding techniques

Quality Requirements

Precise dimensions demand injection or compression molding

Consistent wall thickness suits rotational molding processes

Surface finish requirements may limit process options

Design Flexibility

Undercuts and complex features need injection molding

Internal features work well with rotational molding

Simple shapes cost less with thermoforming methods

TEAM MFG - Your Premier Plastic Molding Partner

At TEAM MFG, we bring two decades of excellence in advanced plastic molding solutions. Our state-of-the-art facility masters injection, blow, rotational, and thermoforming processes, delivering precision from micro-medical components to large industrial parts.

Our ISO-certified operations and expert team ensure superior quality, competitive pricing, and rapid turnaround. Whether you need prototype development or high-volume production, TEAM MFG transforms your concepts into reality.

Contact us today for a free consultation!

Reference Sources

Blow Molding

Injection moulding

Extrusion Molding

Compression Molding

Rotational Molding

Thermoforming

Frequently Asked Questions (FAQs) About Plastic Molding

Q: What are the main differences between injection and compression molding?

Injection molding suits complex, small parts at high volumes with tight tolerances. Compression molding better suits large, simple parts with reinforced materials.

Q: When should I choose blow molding over injection molding?

Choose blow molding for hollow containers like bottles and tanks. It's more economical for hollow parts than injection molding's complex tooling.

Q: Which molding process is best for large, hollow parts?

Rotational molding excels for large hollow parts like tanks and containers. It provides uniform wall thickness without weld lines or stress points.

Q: How does thermoforming differ from other molding processes?

Thermoforming shapes heated plastic sheets using vacuum or pressure. It offers low tooling costs and suits large, shallow parts like packaging.

Q: What are the advantages of extrusion molding?

Extrusion creates continuous profiles efficiently, ideal for pipes, tubing, and window frames. It enables consistent cross-sections at high production rates.

Q: Which process provides the best surface finish quality?

Injection molding typically delivers the finest surface finish. Compression molding also provides excellent surfaces for large, flat parts.

Q: How do material costs compare among different processes?

Injection molding minimizes waste but requires specific grades. Thermoforming may have higher scrap rates. Rotational molding uses cost-effective powders.

Q: What production volumes justify injection molding investment?

High volumes (100,000+ parts annually) typically justify injection molding's higher tooling costs through faster cycles and automation.

Q: How do I select between rotational molding and blow molding?

Choose rotational molding for larger parts with complex shapes. Select blow molding for higher volume container production.

Q: Which process offers the lowest startup costs?

Thermoforming typically has lowest tooling costs, followed by rotational molding. Injection molding requires highest initial investment.