Have you ever wondered how plastic products are made with such precision and consistency? The answer lies in the injection molding process, where molten plastic is injected into a mold cavity to create the desired shape. However, the success of this process heavily relies on the proper design and placement of gates.

Gates are the small openings through which the molten plastic enters the mold cavity, and their design can make or break the quality of the final product.In this post, you'll learn about the different types of gates used in injection molding and how each impacts the manufacturing process.

What Is An Injection Molding Gate?

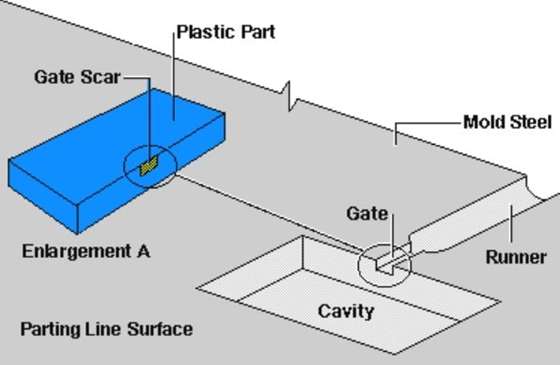

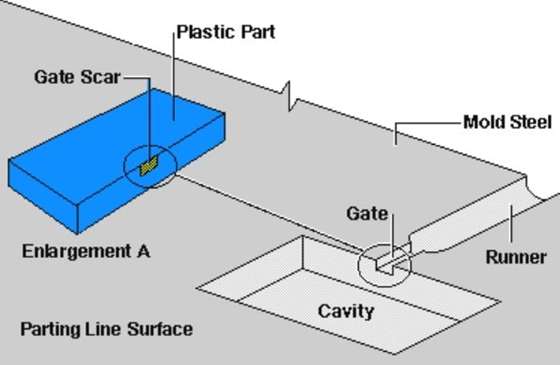

An injection molding gate is a small opening that allows molten plastic to enter the mold cavity. It acts as a passageway, connecting the runner system to the part being molded.

Gates play a crucial role in the injection molding process. They control the flow rate, pressure, and direction of the molten plastic as it fills the cavity. Proper gate design ensures that the cavity is filled evenly and efficiently, resulting in high-quality parts with minimal defects.

The type, size, and location of gates can significantly influence the quality of molded parts. They affect:

Flow patterns and filling behavior

Cooling rates and shrinkage

Weld line formation

Surface appearance and aesthetics

Part strength and mechanical properties

Choosing the right gate design is essential for optimizing the injection molding process. It requires careful consideration of factors such as part geometry, material properties, and production requirements.

A simplified diagram showing the function of an injection molding gate.

Why Is Gate Design Important in Injection Molding?

Gate design is a critical aspect of injection molding. It directly impacts the quality of the final product. A well-designed gate ensures that molten plastic flows smoothly and evenly into the mold cavity. This results in parts with consistent dimensions, appearance, and mechanical properties.

On the other hand, poor gate design can lead to various defects and issues:

Short shots: Incomplete filling of the mold cavity

Weld lines: Visible lines where flow fronts meet

Sink marks: Surface depressions caused by uneven cooling

Warpage: Distortion of the part due to non-uniform shrinkage

Burn marks: Discoloration from overheating of the plastic

These defects not only affect the aesthetics of the part but also its functionality and durability. They can lead to increased scrap rates, rework, and customer complaints.

In contrast, well-designed gates offer numerous benefits:

Improved part quality and consistency

Reduced cycle times and increased productivity

Minimized material waste and scrap

Enhanced mechanical strength and performance

Easier post-molding operations (e.g., gate removal)

By optimizing gate design, manufacturers can streamline their injection molding process. They can produce high-quality parts more efficiently and cost-effectively.

Key Considerations for Gate Design

When designing gates for injection molding, there are several important factors to keep in mind. These considerations can make or break the success of your molded parts. Let's take a closer look at each one.

Gate Placement

Where you place the gate on your part is crucial. It determines how the molten plastic flows into the mold cavity. Ideally, you want to locate the gate:

At the thickest section of the part

Away from visible surfaces and key features

In a way that minimizes flow distance and resistance

Proper gate placement helps ensure even filling, reduces weld lines, and minimizes visible gate marks.

Gate Size

The size of the gate also plays a significant role. It affects the injection speed, pressure, and overall flow behavior. A gate that's too small can cause:

Incomplete filling (short shots)

High shear stress and material degradation

Longer cycle times and reduced efficiency

On the other hand, an oversized gate may lead to excessive material use and longer gate freeze times. Finding the optimal gate size is key to achieving a balance between part quality and production efficiency.

Part Shape and Finish

The geometry and desired surface finish of your part influence gate selection. Complex shapes, thin walls, and aesthetic requirements may dictate specific gate types. For example:

Edge gates for flat, wide parts

Pin gates for small, cylindrical components

Hot tip gates for parts with high surface quality demands

Matching the gate design to the part characteristics ensures better moldability and reduces the risk of defects.

Number of Gates Required

Depending on the size and complexity of your part, you may need multiple gates. This is especially true for large, flat components or parts with intricate features. Using multiple gates can:

Improve filling and packing of the mold cavity

Reduce weld lines and other flow-related defects

Shorten cycle times by allowing faster cooling

However, adding more gates also increases tooling costs and complexity. It's important to find the right balance based on your specific application and requirements.

| Consideration | Impact |

| Gate Placement | Flow behavior, weld lines, gate marks |

| Gate Size | Filling, shear stress, cycle time |

| Part Shape and Finish | Moldability, defects, surface quality |

| Number of Gates | Filling, packing, cycle time, tooling cost |

Summary of key gate design considerations and their impact on injection molding.

Types Of Injection Molding Gates

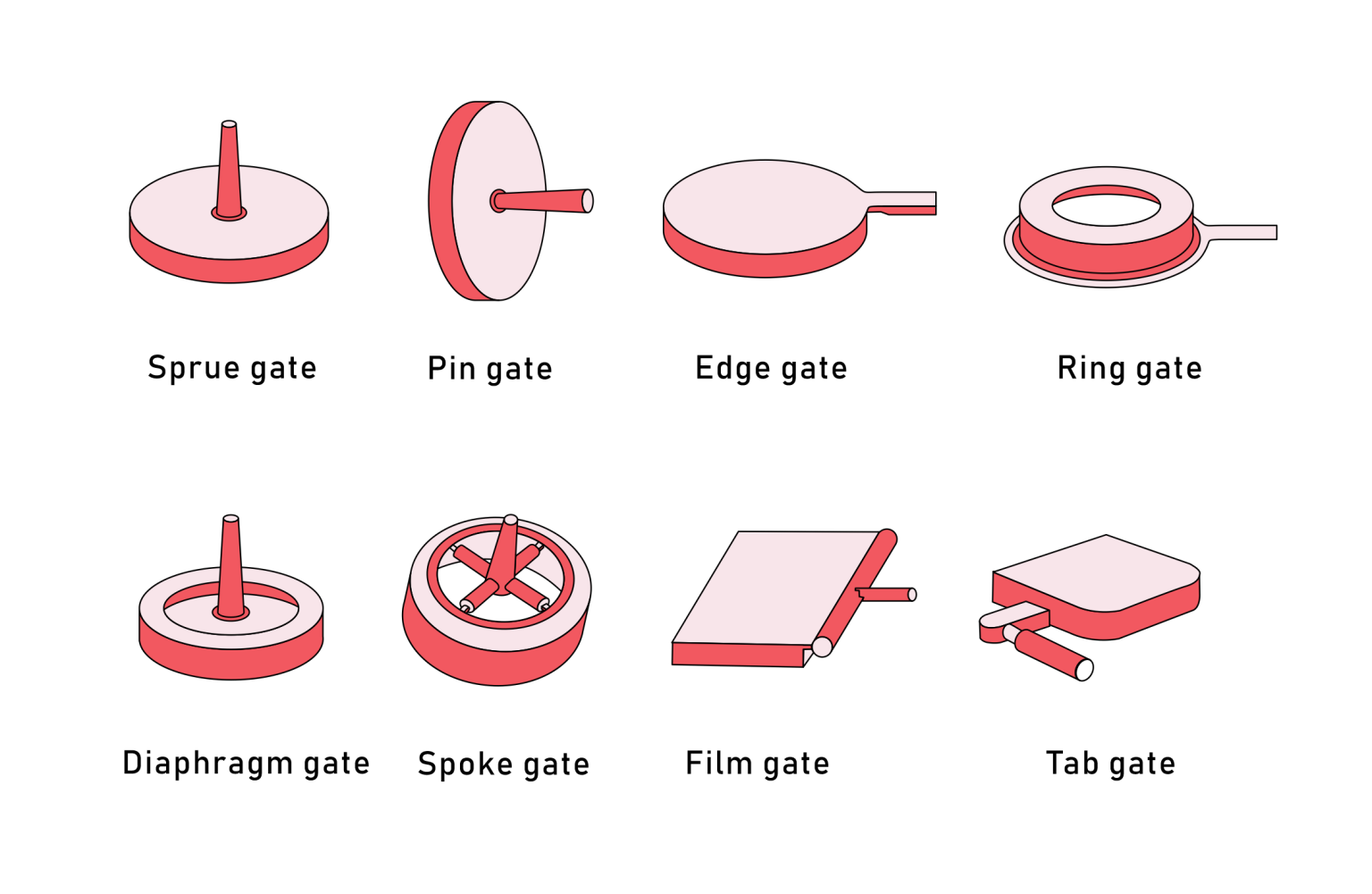

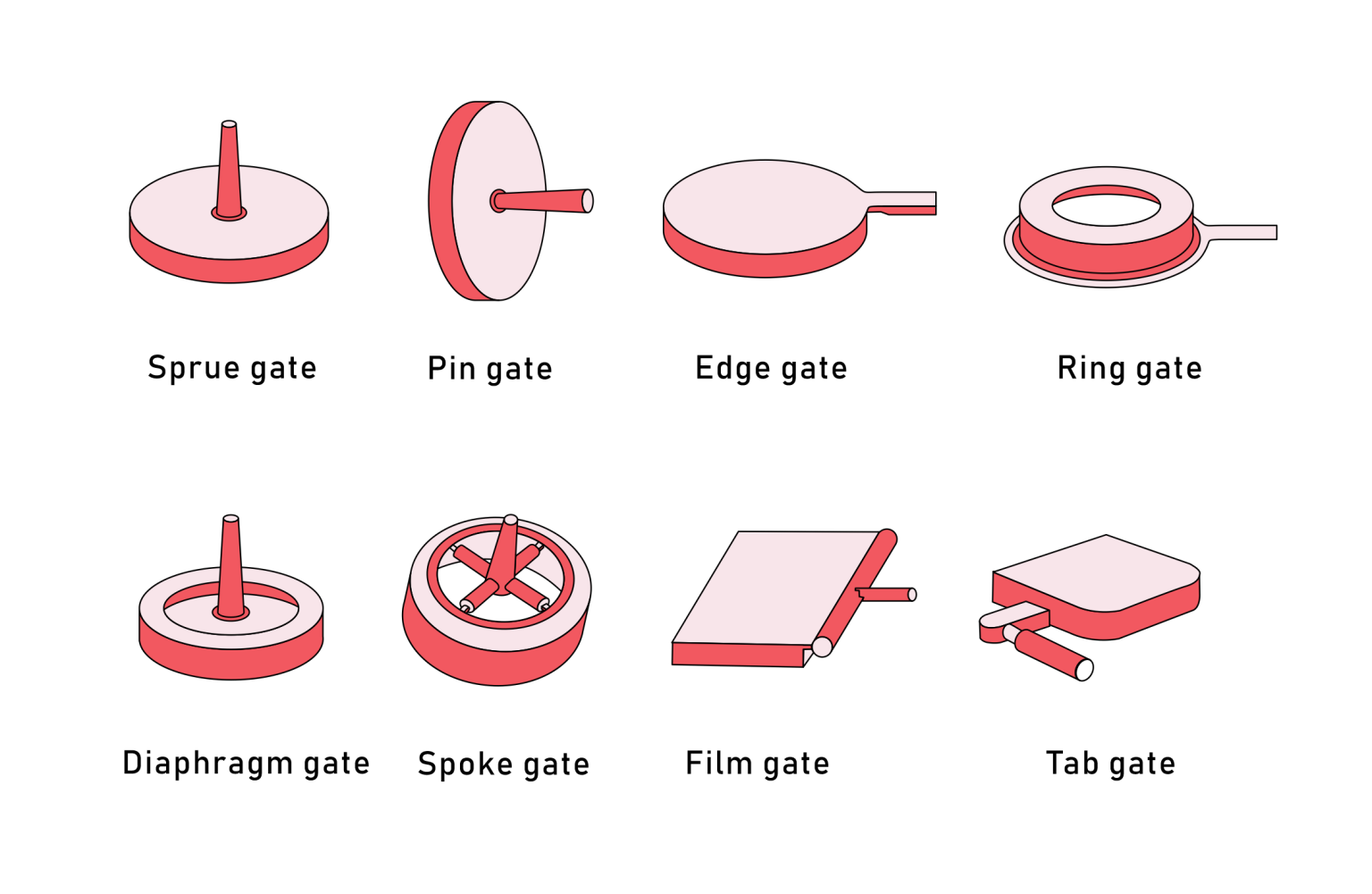

Injection molding gates come in various shapes and sizes, each with its own unique characteristics and applications. Let's explore some of the most common types of gates used in the industry.

1. Direct or Sprue Gates

Direct or sprue gates are the simplest and most basic type of injection molding gate. They consist of a straight, tapered channel that connects the nozzle directly to the mold cavity.

Characteristics:

Simple design and easy to manufacture

Large gate size allows for high flow rates

Suitable for thick-walled parts and large volumes

Advantages:

Low tooling costs and short lead times

Efficient for filling large, simple parts quickly

Minimal shear stress and material degradation

Disadvantages:

Leaves a large, visible gate mark on the part

May require manual gate removal and finishing

Not ideal for parts with thin walls or intricate features

Applications:

Large, thick-walled components

Non-critical parts where aesthetics are not a priority

Prototyping and low-volume production runs

2. Edge Gates

Edge gates are located at the edge of the part, usually along the parting line. They offer a simple and effective solution for many injection molding applications.

Characteristics:

Rectangular cross-section that tapers from the runner to the part

Can be easily trimmed or removed post-molding

Suitable for flat, thin-walled parts

Advantages:

Uniform filling and packing of the mold cavity

Minimal flow resistance and shear stress

Reduced risk of weld lines and other flow-related defects

Disadvantages:

Leaves a visible gate mark on the edge of the part

May require manual gate removal and finishing

Limited to parts with simple geometries and uniform wall thickness

Applications:

Flat, thin-walled components (e.g., plates, covers, panels)

Parts with non-critical appearance requirements

High-volume production runs

3. Submarine Gates

Also known as tunnel gates or sub gates, submarine gates are located below the parting line. They offer a hidden gate solution for parts with high aesthetic requirements.

Characteristics:

Angled or curved channel that enters the part below the surface

Gate is automatically trimmed during ejection

Suitable for small, cylindrical parts or those with undercuts

Advantages:

Leaves no visible gate mark on the part surface

Automatic gate removal reduces post-molding operations

Improved part appearance and quality

Disadvantages:

More complex and expensive tooling compared to other gate types

Limited gate size and flow rate

May cause uneven filling or packing in some cases

Applications:

Small, cylindrical components (e.g., pins, bushings, plugs)

Parts with high aesthetic requirements

Medical or consumer products where gate marks are unacceptable

4. Cashew Gates

Cashew gates, named after their resemblance to a cashew nut, are a variation of the submarine gate. They are used for parts with specific flow or gating requirements.

Characteristics:

Curved or S-shaped channel that enters the part at an angle

Gate is automatically trimmed during ejection

Suitable for parts with non-linear flow paths

Advantages:

Allows gating in hard-to-reach areas or at an angle

Automatic gate removal reduces post-molding operations

Improved part appearance and quality

Disadvantages:

Complex and expensive tooling compared to other gate types

Limited gate size and flow rate

May cause uneven filling or packing in some cases

Applications:

Parts with complex geometries or non-linear flow paths

Components with specific gating requirements or limitations

High-aesthetic parts where gate marks must be hidden

5. Diaphragm Gates

Diaphragm gates, also known as circular gates, are used for parts with cylindrical or conical shapes. They provide a uniform, radial flow of material into the mold cavity.

Characteristics:

Circular gate that surrounds the part or is located at the center

Provides a balanced, radial flow of material

Suitable for cylindrical or conical parts

Advantages:

Uniform filling and packing of the mold cavity

Reduced risk of weld lines and other flow-related defects

Improved part strength and consistency

Disadvantages:

May leave a visible gate mark on the part surface

Requires manual gate removal and finishing

Limited to parts with specific geometries

Applications:

Cylindrical or conical components (e.g., cups, containers, funnels)

Parts with a balanced, radial flow requirement

Products where gate placement at the center or periphery is desired

6. Hot Runner Valve Gates

Hot runner valve gates are used in conjunction with hot runner systems. They provide precise control over the flow of material and offer clean, gate-free part surfaces.

Characteristics:

Valve pin that controls the flow of material into the mold cavity

Provides a clean, gate-free part surface

Suitable for high-volume production and multi-cavity molds

Advantages:

Precise control over material flow and injection

Eliminates the need for gate removal and finishing

Reduced cycle times and improved production efficiency

Disadvantages:

Higher initial investment and maintenance costs

Complex setup and control systems required

May not be suitable for all materials or part geometries

Applications:

High-volume production runs with strict quality requirements

Multi-cavity molds for small, precise parts

Medical, automotive, or consumer products with no visible gate marks

7. Hot Runner Thermal Gates

Hot runner thermal gates are another type of gate used with hot runner systems. They offer improved flow and reduced cycle times compared to traditional cold runner systems.

Characteristics:

Heated nozzle that maintains material temperature and flow

Provides a clean, gate-free part surface

Suitable for high-volume production and multi-cavity molds

Advantages:

Improved material flow and reduced pressure drop

Eliminates the need for gate removal and finishing

Reduced cycle times and improved production efficiency

Disadvantages:

Higher initial investment and maintenance costs

Complex setup and control systems required

May not be suitable for all materials or part geometries

Applications:

High-volume production runs with strict quality requirements

Multi-cavity molds for small, precise parts

Medical, automotive, or consumer products with no visible gate marks

8. Fan Gates

Fan gates are a type of edge gate with a wide, fan-shaped opening. They are used for parts that require rapid filling and uniform distribution of material.

Characteristics:

Wide, fan-shaped gate that tapers from the runner to the part

Provides rapid filling and uniform distribution of material

Suitable for flat, thin-walled parts with large surface areas

Advantages:

Uniform filling and packing of the mold cavity

Reduced risk of weld lines and other flow-related defects

Improved part strength and consistency

Disadvantages:

Leaves a visible gate mark on the edge of the part

May require manual gate removal and finishing

Limited to parts with simple geometries and uniform wall thickness

Applications:

Flat, thin-walled components with large surface areas (e.g., panels, lids, trays)

Parts with non-critical appearance requirements

High-volume production runs

9. Pin Gates

Pin gates are small, cylindrical gates that are used for parts with thick walls or large cross-sections. They offer a concentrated flow of material into the mold cavity.

Characteristics:

Small, cylindrical gate that extends from the runner to the part

Provides a concentrated flow of material into thick or large parts

Suitable for parts with non-critical appearance requirements

Advantages:

Efficient filling and packing of thick or large parts

Reduced risk of short shots or incomplete filling

Minimal shear stress and material degradation

Disadvantages:

Leaves a visible gate mark on the surface of the part

May require manual gate removal and finishing

Limited to parts with thick walls or large cross-sections

Applications:

Thick-walled or large components (e.g., structural parts, housings, brackets)

Parts with non-critical appearance requirements

Low to medium-volume production runs

Factors Affecting Gate Selection

Choosing the right gate for your injection molding project is not a one-size-fits-all decision. Several factors come into play when selecting the optimal gate type and location. Let's explore these considerations in more detail.

Material Properties and Flow Characteristics

The type of plastic material you're using has a significant impact on gate selection. Different materials have varying flow properties, such as viscosity, shear sensitivity, and thermal stability. These characteristics influence how the molten plastic behaves as it enters and fills the mold cavity.

For example, high-flow materials like polyethylene (PE) and polypropylene (PP) may require larger gates to accommodate their fast flow rates. On the other hand, engineering plastics like polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) may benefit from smaller, more precise gates to control their flow and minimize shear stress.

| Material | Flow Characteristics | Suitable Gate Types |

| PE, PP | High flow, low viscosity | Large gates (e.g., sprue, edge) |

| PC, ABS | Moderate flow, shear sensitive | Small gates (e.g., pin, valve) |

| Nylon, POM | Low flow, high viscosity | Medium gates (e.g., fan, submarine) |

Table 1: Material flow characteristics and suitable gate types.

Part Geometry and Wall Thickness

The shape and dimensions of your part also play a role in gate selection. Parts with complex geometries, thin walls, or non-uniform thicknesses may require specific gate types to ensure proper filling and minimize defects.

For instance, thin-walled parts may benefit from edge gates or fan gates, which provide a wide, shallow flow path to fill the cavity quickly and evenly. Thick-walled parts, on the other hand, may require pin gates or sprue gates to deliver a concentrated flow of material into the deep sections of the mold.

Figure 1: The relationship between part geometry and gate selection.

Mold Design and Construction

The design and construction of your injection mold can limit or enable certain gate types. The parting line location, ejector pin placement, and cooling channel layout all influence where and how gates can be incorporated into the mold.

Some gate types, like submarine gates or cashew gates, require specific mold features or additional machining to accommodate their unique shapes and entry points. Others, like hot runner gates, may necessitate more complex and expensive mold builds to integrate the heated manifold and nozzle components.

It's crucial to consider the mold design early in the process and collaborate with experienced toolmakers to ensure that the selected gate type is feasible and optimal for your specific application.

Production Volume and Efficiency Requirements

Your production volume and efficiency goals also influence gate selection. Different gate types offer varying levels of productivity, cycle times, and post-molding requirements.

For high-volume production runs, you may opt for gate types that minimize cycle times and enable faster part ejection, such as valve gates or thermal gates. These gate types also reduce the need for manual gate removal and finishing, further streamlining the production process.

However, these advanced gate systems come with higher initial costs and complexity compared to simpler gate types like edge gates or sprue gates. For low to medium-volume runs, these basic gate types may be more cost-effective while still meeting your quality and efficiency requirements.

| Production Volume | Efficiency Goals | Suitable Gate Types |

| High | Minimal cycle times, automated trimming | Valve gates, thermal gates |

| Medium | Balanced productivity and cost | Fan gates, submarine gates |

| Low | Cost-effective, manual trimming | Edge gates, sprue gates |

Table 2: Production volume, efficiency goals, and suitable gate types.

By carefully evaluating these factors and consulting with injection molding experts, you can select the optimal gate type for your specific application. The right gate selection can greatly enhance the quality, efficiency, and profitability of your injection molding project.

Conclusion

Selecting the proper gate type is crucial in injection molding. It impacts the quality and efficiency of the final product. Carefully consider the type and placement of gates in your designs. This decision can prevent defects and improve manufacturing outcomes. Consult with experienced professionals for guidance. They can help optimize your gate design and ensure the best results.

Team Mfg is your trusted partner for precision injection molding solutions. Contact us today, and let our experts optimize your project for success.